Method of producing chlorides from ethane

A technology for chlorides and chlorinated products, applied in chemical instruments and methods, organic chemistry, preparation of dehydrohalogenation, etc., can solve the problems of increased cost of vinyl chloride and increased difficulty in oil exploitation, and improved economic and environmental benefits. , The effect of reducing the preparation cost and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

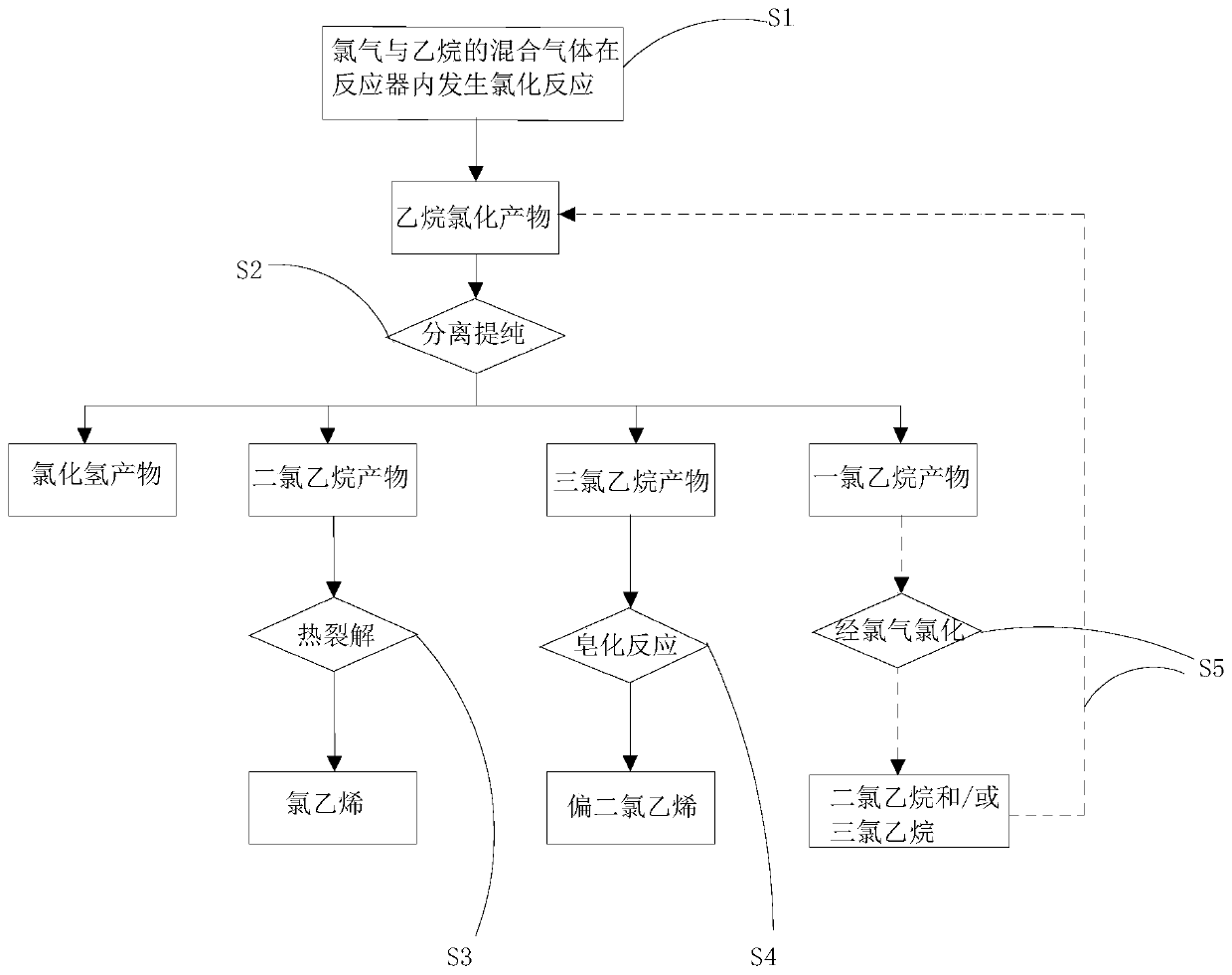

Method used

Image

Examples

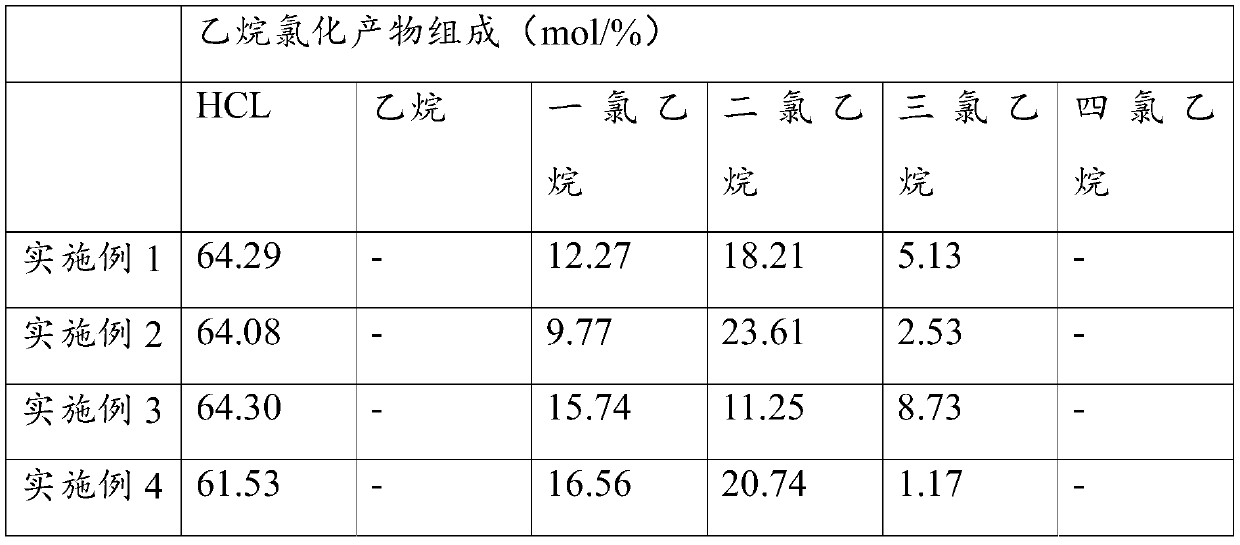

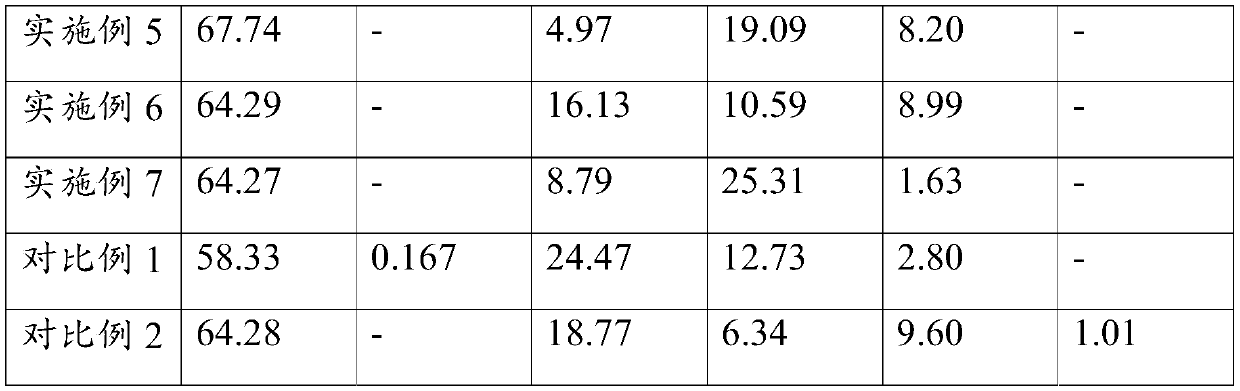

Embodiment 1

[0085] Snake tube preheater ensures that the mixed gas at the outlet of the preheater is ≥150℃.

[0086] Tubular carbon steel reactor With heating and cooling heat conduction oil jacket.

[0087] Take 30m 3 Feed the mixed gas with a molar ratio of ethane to chlorine of 1:1.8 into the preheater at a rate of 1 / h, so that the temperature of the mixed gas entering the reactor after preheating is 165℃, and the pressure inside the reactor is controlled to 0.25MpaG. The oil temperature of the reactor jacket makes the outlet temperature of the reactor 250±5℃, and the mixed gas stays in the mixer for 5.0s.

[0088] In this example, the ethane conversion rate is 95.27%.

Embodiment 2

[0090] The specific operation is the same as in Example 1, except that the oil temperature of the reactor jacket is controlled so that the reactor outlet temperature is 200±5°C and the ethane conversion rate is 95.11%.

Embodiment 3

[0092] The specific operation is the same as in Example 1, except that the oil temperature of the reactor jacket is controlled so that the outlet temperature of the reactor is 300±5°C and the ethane conversion rate is 96.28%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com