A kind of modified flat glass fiber reinforced PBT composite material and preparation method thereof

A flat glass fiber and composite material technology, applied in the field of polyester polymer material preparation, can solve the problem of inability to solve the warpage degree of glass fiber reinforced PBT composition cohesive profiles, and inability to effectively improve the compatibility of inorganic materials and organic polymers It can not effectively improve the notched impact strength and other problems, so as to increase the interface compatibility, overcome the low impact strength and reduce the warpage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

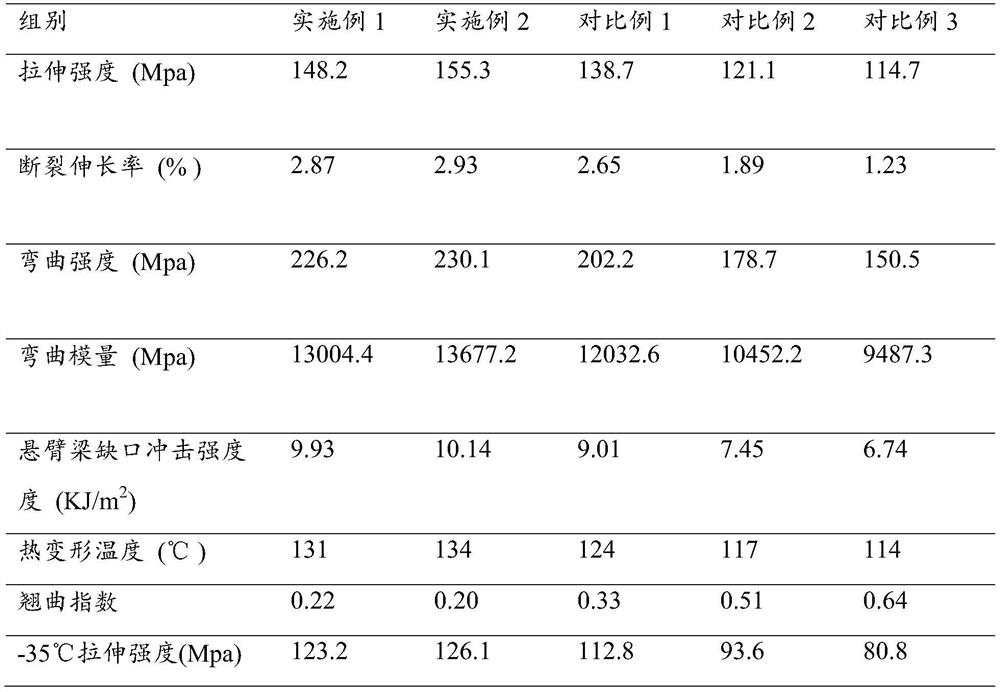

Examples

preparation example 1

[0081] Preparation of doped modified PBT polyester

[0082] In a reactor with stirring, condensing and splitting and decompression devices, add 0.7kg terephthalic acid, 0.65kg 1,4-butanediol, 1.2g tetraisopropyl titanate and 18g mesoporous silica Nanoparticles; after reacting for 2 hours under normal pressure and 240°C, gradually reduce the pressure to 0.08-0.09KPa (total depressurization time 0.6h), and continue the polycondensation reaction for 1.5h; the intrinsic viscosity of the synthesized PBT is 0.82dL / g, Dry and set aside.

preparation example 2

[0084] Preparation of PET-ABS compound composition

[0085] (1) After drying the PET and ABS resin raw materials at a temperature of 100° C. for 4 hours according to the mass ratio of 1:0.3, they were pulverized with an engineering plastic grinder and passed through a 200-mesh sieve, and dried to obtain a PET-ABS mixed raw material;

[0086] (2) Weigh 60 parts of PET-ABS mixture after drying in the above steps, 10 parts of ethylene-methyl acrylate copolymer, 3 parts of butadiene-styrene-methyl methacrylate, 5 parts of surface-treated hollow Glass beads and 2 parts of mesoporous silica treated with silane coupling agent were stirred in a high-speed mixer for 5 minutes until uniform;

[0087] (3) Add the above-mentioned uniformly mixed materials into the feeding port of the twin-screw extruder, melt and extrude through the twin-screw extruder, granulate, and dry in an oven, then pulverize with a pulverizer and pass through a 200-mesh sieve to obtain PET-ABS Mixing composition; ...

preparation example 3

[0089] Preparation of surface-modified flat glass fibers

[0090] Configure isocyanate group propyl triethoxysilane-ethanol solution 1.2kg, so that the isocyanate group propyl triethoxysilane content is 12wt%; Glass fibers, which have a length of 500-600 μm, a width of 20-25 μm, and a thickness of 3-5 μm) are uniformly sprayed, wherein the weight ratio of glass fibers to isocyanate-propyltriethoxysilane-ethanol solution is 1:1; The treated glass fiber is placed in a drying oven, dried at 90°C to remove the solvent, and the surface-treated flat glass fiber is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com