A moisture-absorbing and heating fabric based on functional polyester and its preparation process

A technology for moisture absorption and heat generation, fabrics, applied in the manufacture of rayon, conjugated synthetic polymer rayon, textile and other directions, it can solve the problems of moisture absorption speed, moisture diffusion speed and evaporation speed, and the fabric structure lacks moisture diffusion gradient and air permeability. The problem of moisture permeability and drainage performance decline, to achieve the effect of speeding up the speed of moisture removal, good water absorption performance, and speeding up the speed of sweating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below through specific embodiments.

[0032] The moisture-absorbing and heat-generating fabric based on functional polyester of the present invention includes a surface fabric and an inner fabric.

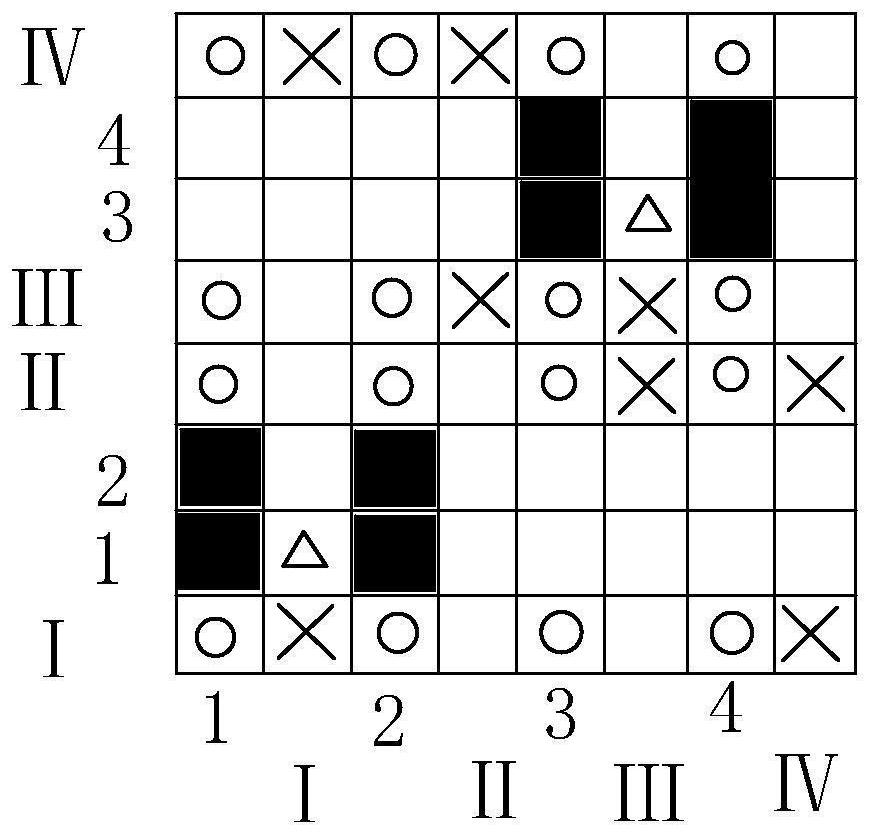

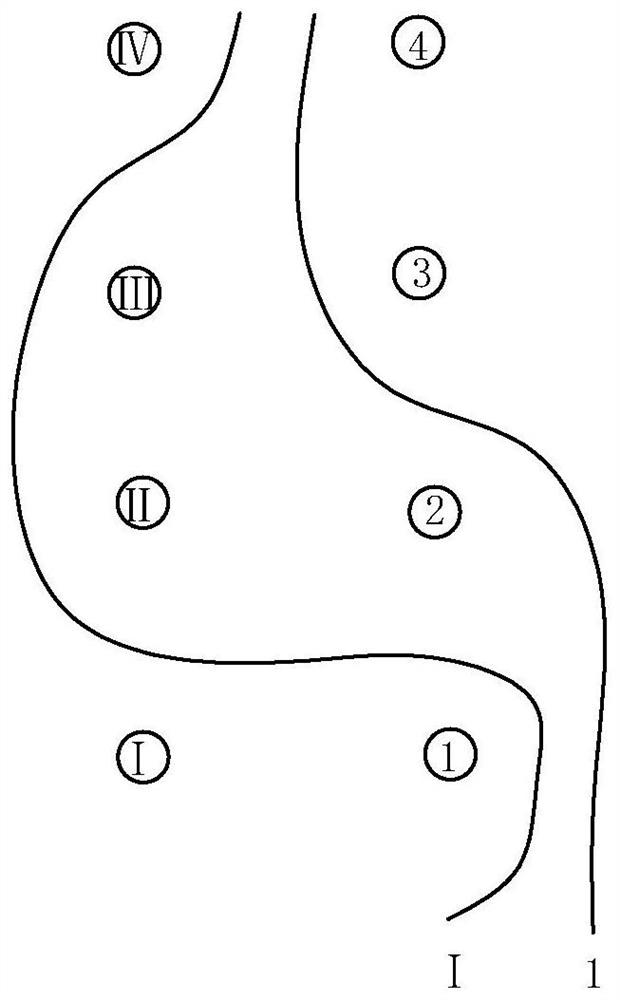

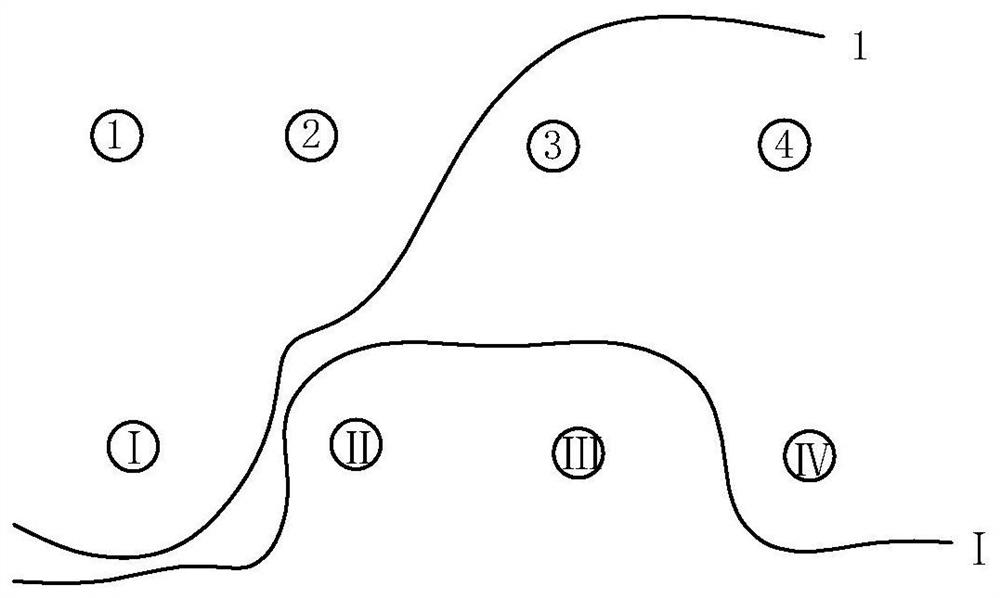

[0033] Such as Figures 1 to 3 As shown, the surface weave of the surface fabric is a square weave, and the inner weave of the inner fabric is two upper and two lower left twill weaves. The knot structure is formed by interweaving the inner warp and the surface weft. The surface fabric and the inner fabric have independent warp and weft yarns, and overlap each other to form a two-layer fabric. Bonded together, it has good thermal insulation properties;

[0034] The arrangement ratio of surface warp yarns and inner warp yarns is 1:1, and the warp floating long lines of the surface weave cover the inner warp joints, and the joint points of the binding weave are located in the center of the warp floating long lines of the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com