A Prediction Method of Temperature Field in Cutting Area for Ultra-low Temperature Cooling Machining

A prediction method and ultra-low temperature technology, applied in the direction of design optimization/simulation, geometric CAD, etc., can solve the problem that the boundary of the cutting area of the liquid nitrogen cold source and the influence of cutting parameters cannot be accurately reflected, so as to improve the calculation efficiency and accuracy, and improve the Processing quality and processing efficiency, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

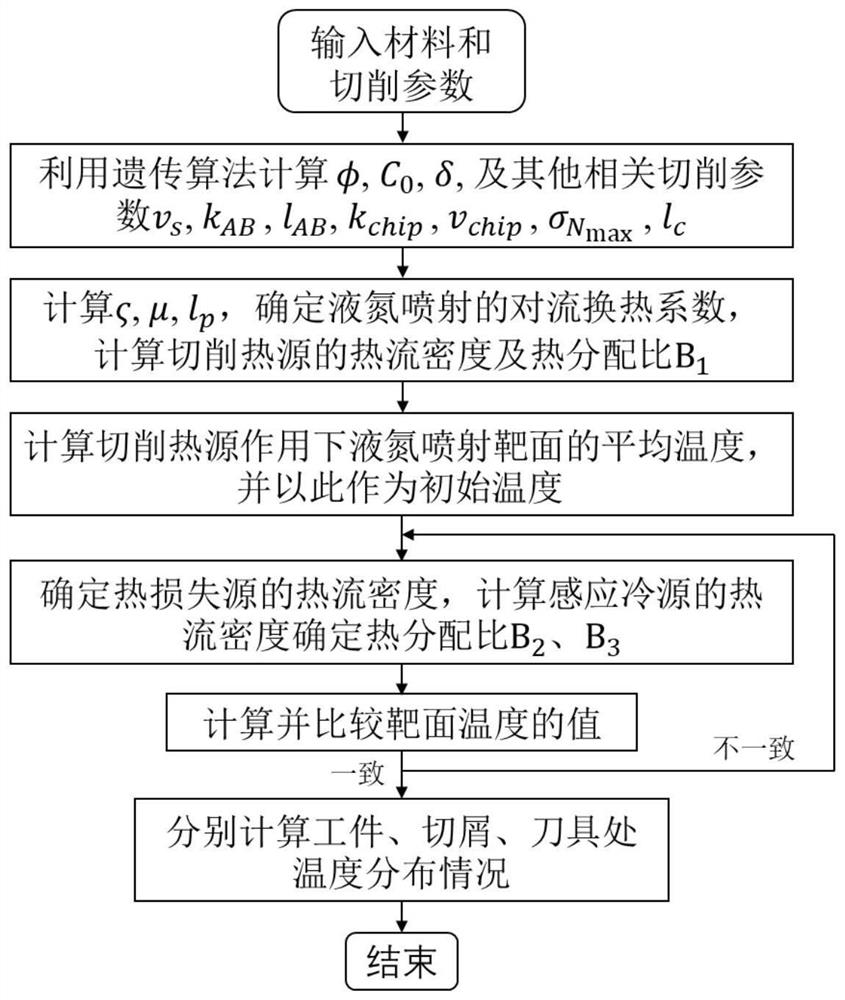

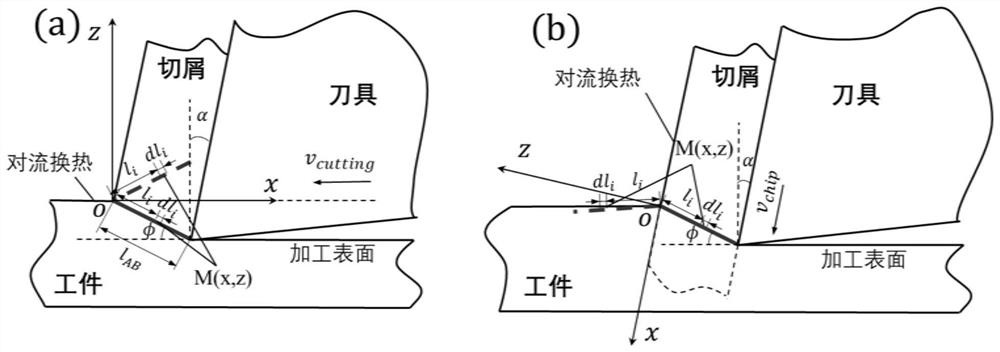

[0136] The detailed implementation of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

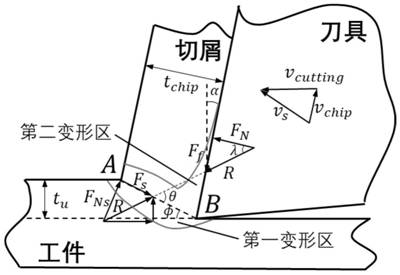

[0137] Taking the external turning of titanium alloy (Ti-6Al-4V) as an example, the workpiece size is Φ100×200, and the cutting process parameter is the cutting depth a p = 0.2mm, feed speed f = 0.15mm / min, spindle speed n = 450rpm; the material of the turning tool is hard alloy, the rake angle α = 5°, the relief angle ψ = 5°, and the cutting width w = 4.5 mm. Liquid nitrogen is applied to the tool surface from the front and rear cutter faces at the same time, and the effective cooling length is l eff = 4.5 mm. The density of titanium alloy ρ=4430kg / m 3 , thermal conductivity λ w =6.7W / mK, specific heat capacity C p =560J / kgK, thermal diffusivity a=2.7×10 -6 m 2 / s, JC material constant A=968MPa, B=380MPa, n=0.421, C=0.0197, m=0.577, melting temperature T m =1668°C. Thermal conductivity of cemented carbide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com