Preparation method of zero-dimensional/two-dimensional structure copper oxide and tourmaline composite photocatalytic material

A technology of composite photocatalysis and two-dimensional structure, which is applied in the field of preparation of composite photocatalytic materials of copper oxide and tourmaline with zero-dimensional/two-dimensional structure, can solve the problems of high cost and complicated preparation process, and achieve the promotion of separation and preparation process Simple, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

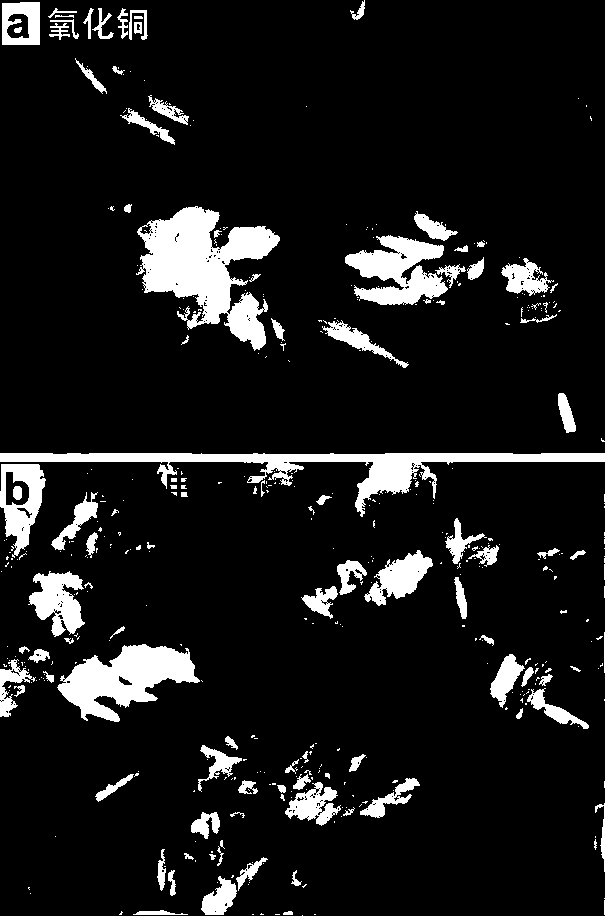

[0019] Add 0.50 g tourmaline powder sample into 40 mL deionized water, stir magnetically for 30 min, and ultrasonically disperse for 30 min, then add 1.25 g copper acetate and stir until completely dissolved to obtain suspension A. Weigh 0.50 g of sodium hydroxide and dissolve it in 20 mL of deionized water to obtain solution B. Under magnetic stirring, solution B was added dropwise to suspension A and stirred continuously for 2 h to obtain suspension C. Finally, the suspension C was put into a 100 mL polytetrafluoroethylene reactor, reacted at 180 °C for 6 h, cooled to room temperature naturally, washed with deionized water, dried at 60 °C, and ground to obtain a zero-dimensional / two-dimensional structure oxidation Copper and tourmaline composite photocatalytic materials, in which the average size of zero-dimensional copper oxide nanoparticles is 10-20 nm, and the average size of two-dimensional copper oxide nanosheets is 200-450 nm.

Embodiment 2

[0021] Add 0.50 g tourmaline powder sample into 40 mL deionized water, stir magnetically for 30 min, and ultrasonically disperse for 30 min, then add 2.50 g copper acetate and stir until completely dissolved to obtain suspension A. Weigh 1.00 g of sodium hydroxide and dissolve it in 20 mL of deionized water to obtain solution B. Under magnetic stirring, solution B was added dropwise to suspension A and stirred continuously for 2 h to obtain suspension C. Finally, the suspension C was put into a 100 mL polytetrafluoroethylene reactor, reacted at 180 °C for 6 h, cooled to room temperature naturally, washed with deionized water, dried at 60 °C, and ground to obtain a zero-dimensional / two-dimensional structure oxidation Copper and tourmaline composite photocatalytic materials, in which the average size of zero-dimensional copper oxide nanoparticles is 15-20 nm, and the average size of two-dimensional copper oxide nanosheets is 250-480 nm.

Embodiment 3

[0023] Add 0.50 g of tourmaline powder sample into 40 mL of deionized water, stir magnetically for 30 min, and ultrasonically disperse for 30 min, then add 2.50 g of copper acetate and stir until completely dissolved to obtain suspension A. Weigh 1.00 g of sodium hydroxide and dissolve it in 20 mL of deionized water to obtain solution B. Under magnetic stirring, solution B was added dropwise to suspension A and stirred continuously for 2 h to obtain suspension C. Finally, the suspension C was put into a 100 mL polytetrafluoroethylene reactor, reacted at 160 °C for 6 h, cooled to room temperature naturally, washed with deionized water, dried at 60 °C, and ground to obtain a zero-dimensional / two-dimensional structure oxidation Copper and tourmaline composite photocatalytic material, in which the average size of zero-dimensional copper oxide nanoparticles is 10-20 nm, and the average size of two-dimensional copper oxide nanosheets is 200-420 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com