Carbon nitride nanosheet (CNNS) composite pH-sensitive hydrogel with Pizza structure as well as preparation method and application of CNNS composite pH-sensitive hydrogel

A technology of composite hydrogel and sheet carbon nitride, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, water pollutants, etc. Small area and other problems, to achieve the effect of convenient recycling and solve recycling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

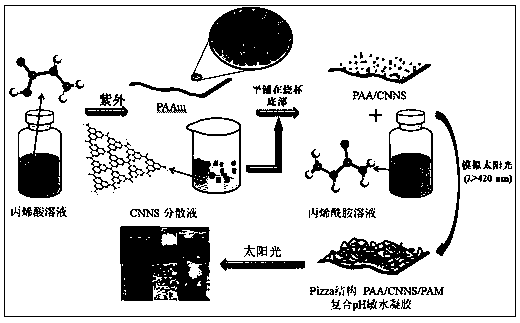

[0026] Example 1: Prepare 8wt% acrylic acid solution with distilled water, take 20ml of the solution and place it in a quartz bottle, then seal it and fill it with nitrogen for 40 minutes; place the quartz bottle filled with nitrogen under a UV lamp with a central wavelength of 365nm and a power of 300w, keeping a distance of 18cm , and irradiate for 100min, the polyacrylic acid film can be obtained; pour out the prepared PAA and solution from the quartz bottle, wash and dry the PAA, intercept 0.08g PAA and place it in the bottom of a beaker with a certain specification, add 2ml of distilled water dropwise, and let it stand for 60min; take 15mg- 30mg CNNS was placed in 5ml distilled water, ultrasonically oscillated for 30min, then introduced into the above-mentioned beaker, and left to stand for 10 hours; then suck out the distilled water that had been clarified on the upper layer, and place it in a thermostat at 50°C for 12 hours to confirm the weight and ratio;

[0027] CNNS / ...

Embodiment 2

[0029] Embodiment 2: synthesis process such as figure 1 As shown, compared with Example 1, the experimental parameters only changed the irradiation time under the simulated solar xenon lamp to 50 minutes, and finally a PAM / CNNS / PAA composite pH-sensitive hydrogel with a mass ratio of 6:3:8 could be obtained.

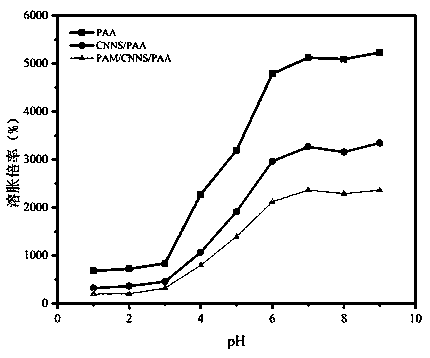

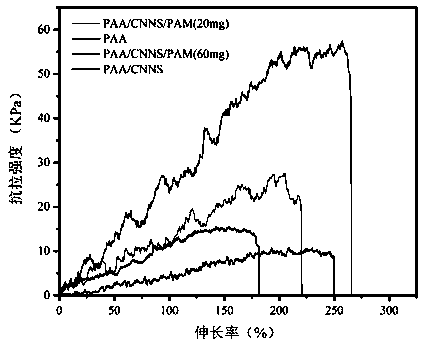

[0030] Combining Examples 1 and 2, it can be known that the mass ratio of PAM / CNNS / PAA can be controlled by changing the reaction time of light under the xenon lamp; (Mass ratio 2:3:8) The swelling ratio is decreasing, and the decrease is small, but its maximum tensile strength is greatly increased to 57.3KPa, which is nearly 6 times the maximum tensile strength of PAA, which is PAM / CNNS / PAA (mass ratio 2:3:8) 1.1 times the maximum tensile strength; 0.17g PAM / CNNS / PAA (mass ratio 6:3:8) at wavelengths above 420nm, optical power density 100 mWcm -2The cycle experiment diagram of the degradation of 30ml (10mg / L) RhB solution under the xenon lamp irradiation of simulated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com