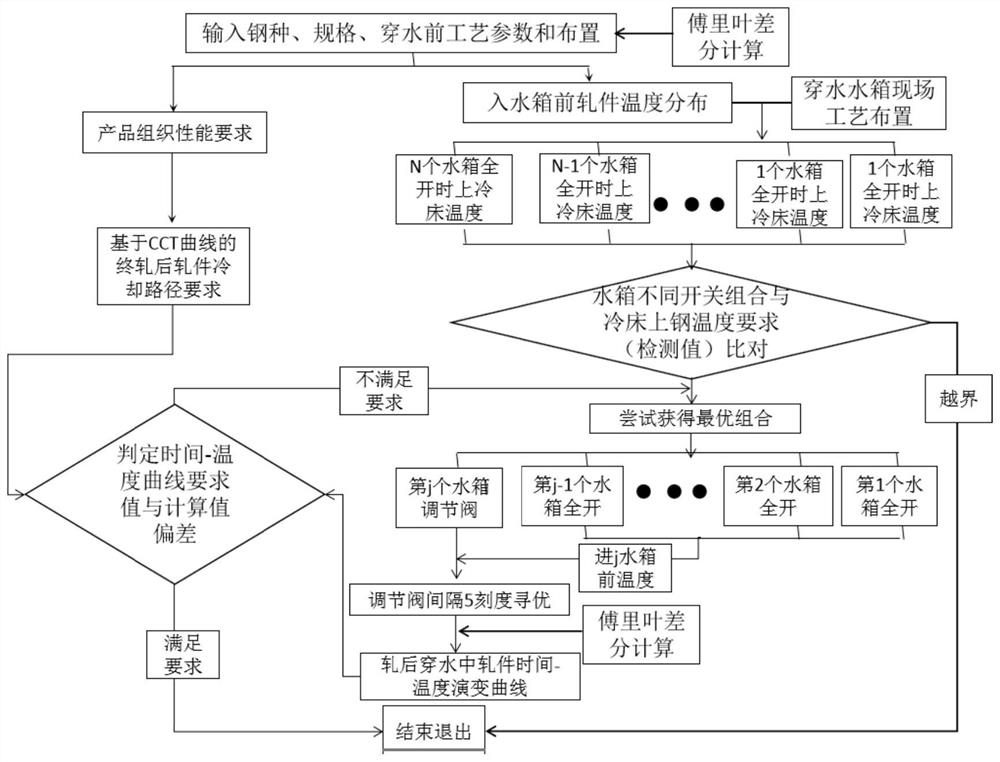

Intelligent calculation method for reverse self-decision temperature control of bar water tank based on trial method

A technology of calculation method and trial method, which is applied in the field of intelligent calculation of reverse self-decision temperature control of bar water tank, which can solve the problems of uneven wear and cooling, unstable heat transfer coefficient value, and temperature deviation of intermediate rolling pieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In a typical hot-rolled bar rolling production line, there are usually 18 stands, including 6 rough rolling stands, 6 intermediate rolling stands, and 6 finishing rolling stands. The rolling start temperature is generally 950°C-1200°C. After 18 passes of rolling, the temperature of the rolled piece after exiting the finishing mill is about 900°C-1100°C. On the one hand, the temperature of the high-temperature rolled piece should be quickly lowered to room temperature for subsequent Finishing;

[0018] On the one hand, according to the metallurgical continuous cooling transformation principle of low-carbon steel materials, the cooling rate caused by a reasonable cooling path can ensure that the high-temperature austenite of the high-temperature rolled piece forms fine ferrite, promotes the refinement of pearlite, and obtains good microstructure and properties ;

[0019] On the one hand, the cooling intensity of the high cooling rate should not be so high that unfavorabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com