Wood polymer composite prepared by using mixed plastic and cotton stalks in domestic garbage, and method for preparing wood polymer composite

A technology of mixing plastic and wood-plastic, which is applied in the field of comprehensive utilization of resources, can solve the problems of unutilized waste plastics and rising production costs of wood-plastic, and achieve low manufacturing costs, up-to-standard processing performance and physical and mechanical properties, and smooth product surfaces Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

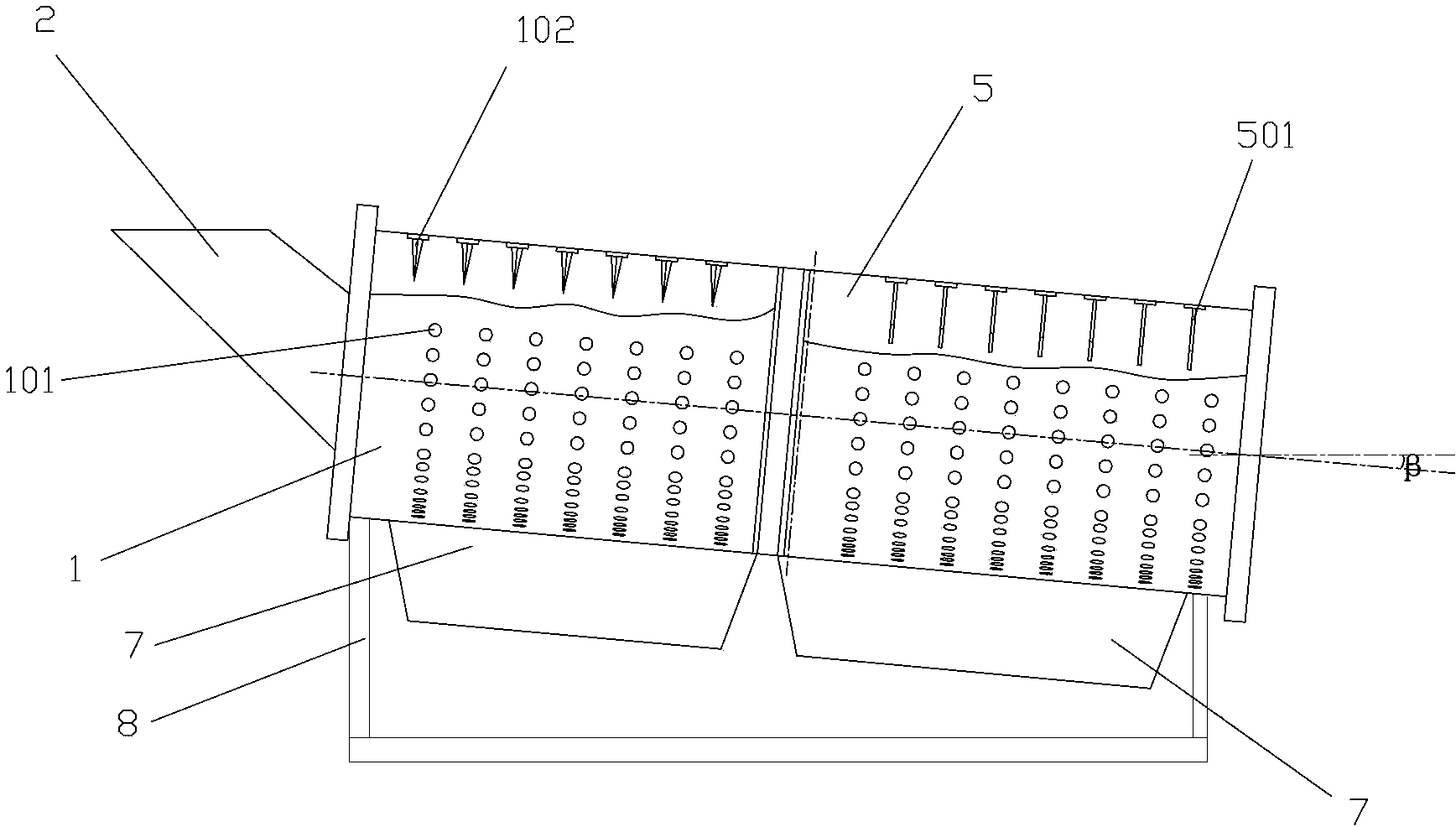

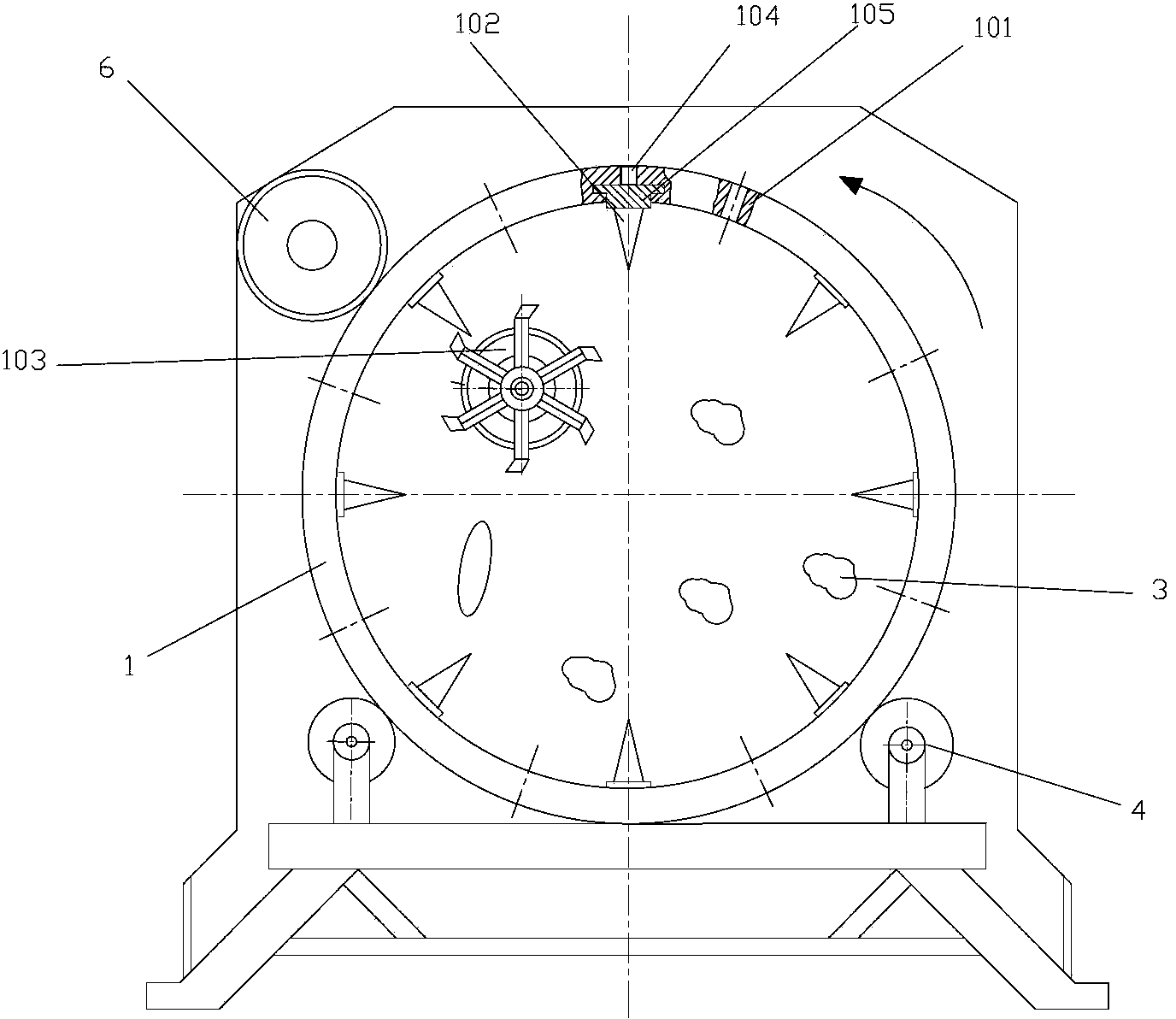

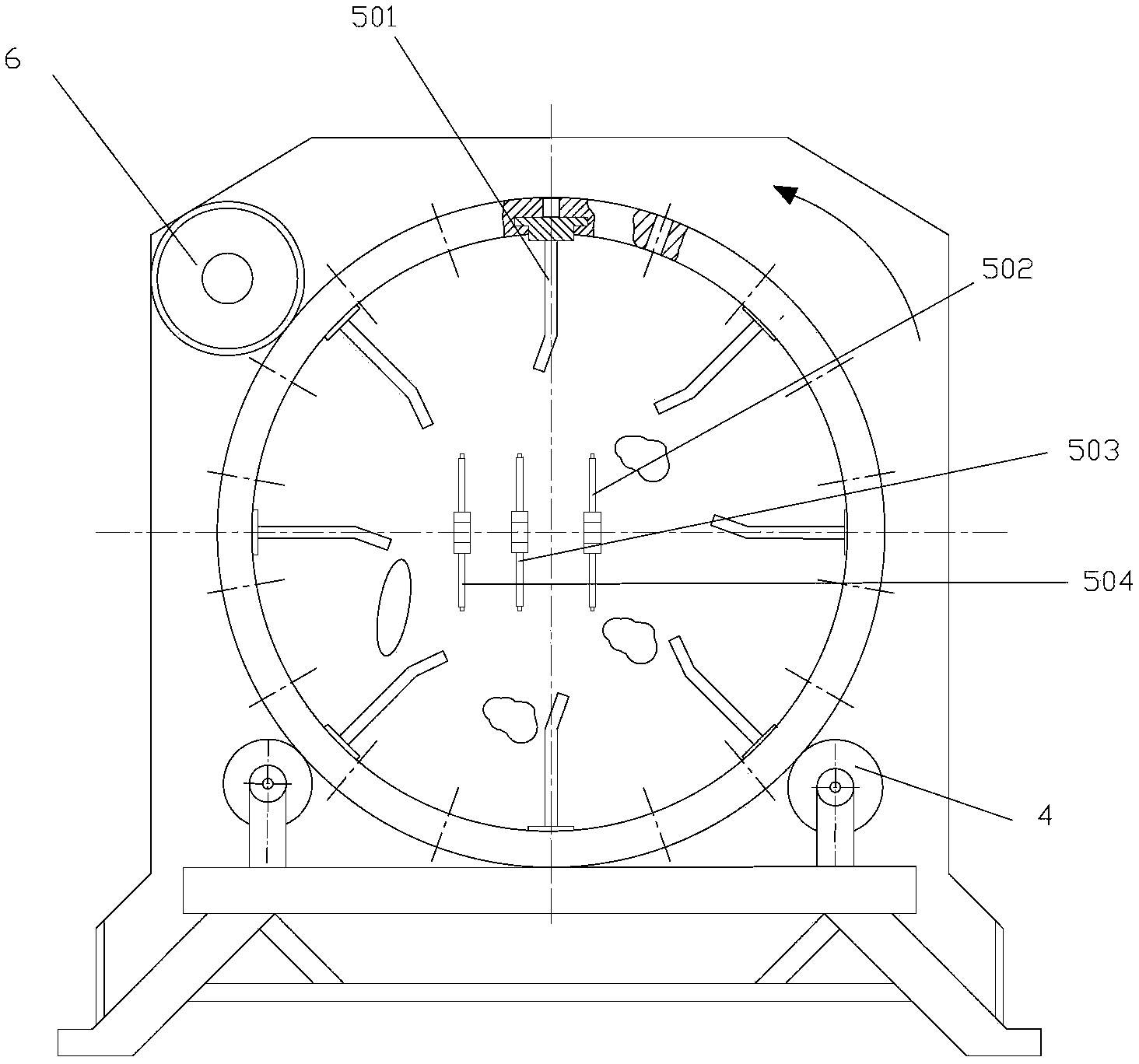

Image

Examples

Embodiment 1

[0051] Table 1 Example 1 WPC formula

[0052]

[0053] The lubricant used in the plastic wood of the present invention is fatty acid amides, including stearic acid amide, oleic acid amide, and palmitic acid amide.

[0054] (1) Dry the cotton stalk fibers crushed to 40-100 mesh in a drying oven at 160°C for 3 hours, so that the cotton stalks can be completely dehumidified and low-molecular volatile substances in the cotton stalk fibers can be removed.

[0055] (2) The municipal solid waste is bag-broken and sorted by two-stage drum sieve, and further air-separated by a double-chamber multifunctional air separator to obtain mixed plastics of polyethylene, polypropylene, and polyvinyl chloride, according to the proportion The polyethylene, polypropylene and polyvinyl chloride are washed and crushed, dried and dehydrated, and granulated to obtain mixed plastic granules with a granulation size of 40-80 mesh.

[0056] (3) In a heating jacket high-speed mixer at a temperature of ...

Embodiment 2

[0064] The preparation method of embodiment 2 is identical with embodiment 1, just formula is different.

[0065] Table 2 Example 2 WPC formula

[0066]

[0067]

Embodiment 3

[0069] The preparation method of embodiment 3 is identical with embodiment 1, just formula is different.

[0070] Table 3 Example 3 WPC formula

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com