A self-cleaning outdoor artificial stone slab and its preparation method

A technology for artificial stone slabs and cleaning households, applied in the field of artificial stone, can solve the problems of difficult cleaning and low durability performance, and achieve the effects of saving production costs, improving compactness and improving self-cleaning performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

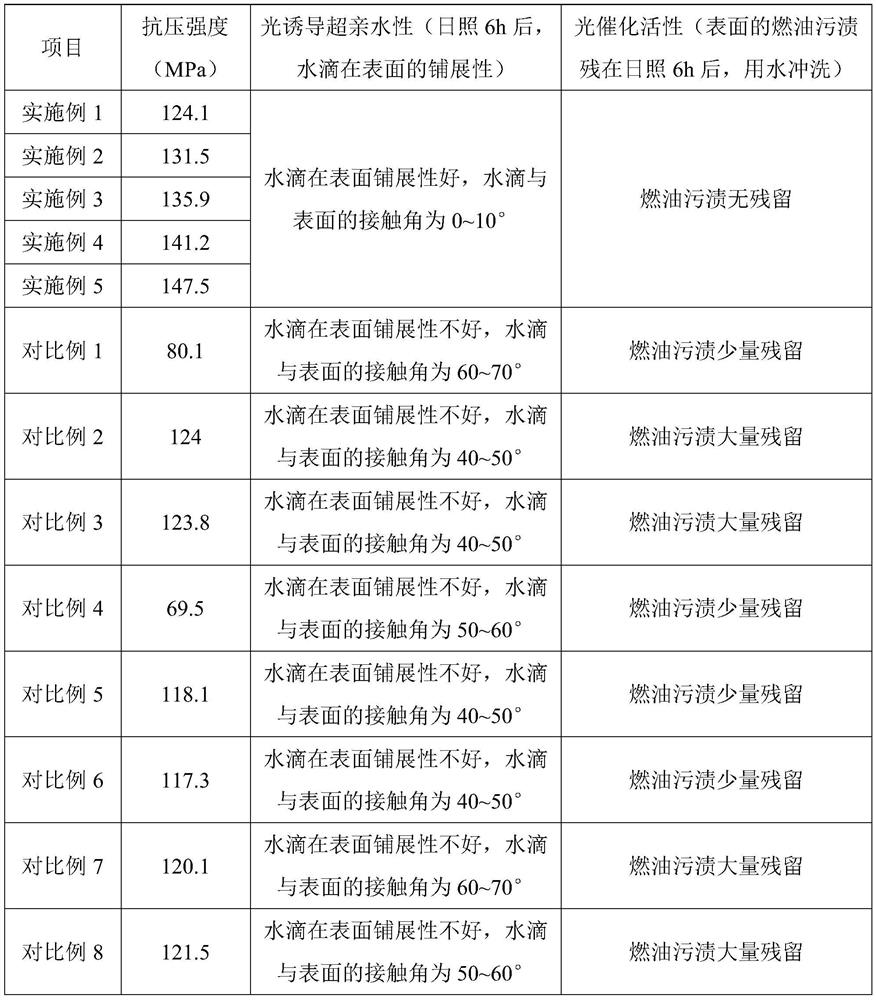

Examples

Embodiment 1

[0033] A self-cleaning artificial stone slab for outdoor use, which is prefabricated from ultra-high-performance mineral powder with a compressive strength of 100-150 MPa, and the ultra-high-performance mineral powder includes the following raw material components in parts by weight: mineral active powder 80 parts of body, 8 parts of titanium dioxide, 150 parts of self-cleaning aggregate, 4 parts of nano-silica, 0.5 parts of water repellent, 10 parts of water, 2 parts of water reducing agent, 4 parts of pigment, the self-cleaning aggregate One or more combinations of quartz sand, river sand, and machine-made sand with a particle size of 20 to 70 meshes are washed and soaked in microsilica powder, nano-titanium dioxide, cement, microbead powder, quartz stone powder, dispersant, retarder, etc. It is made of self-cleaning photocatalytic suspension slurry formed by type water reducer, water and thickener.

[0034]The mass ratio of cement, microsilica powder, nano titanium dioxide,...

Embodiment 2

[0048] Except that the prescription of ultra-high performance mineral powder is different, other conditions are the same as embodiment 1.

[0049] The ultra-high-performance mineral powder includes the following raw material components in parts by weight: 100 parts of mineral active powder, 13 parts of titanium dioxide, 220 parts of self-cleaning aggregate, 8 parts of nano-silica, 2 parts of water repellent, 15 parts of water, 4 parts of water reducing agent, 10 parts of pigment.

Embodiment 3

[0051] Except that the formula of ultra-high performance mineral powder is different, other conditions are the same as embodiment 1

[0052] The ultra-high-performance mineral powder includes the following raw material components in parts by weight: 85 parts of mineral active powder, 9.5 parts of titanium dioxide, 170 parts of self-cleaning aggregate, 5 parts of nano-silica, 0.9 part of water repellent, 11 parts of water, 2.5 parts of water reducer, 5.5 parts of pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com