Ethylene sulfate preparation method

A technology of vinyl sulfate and ethylene glycol, which is applied in electrochemical generators, electrical components, circuits, etc., can solve the problems of not meeting the requirements of green chemical development, high cost, and many wastes, so as to reduce battery expansion and reduce Production cost, effect of suppressing the rate of decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

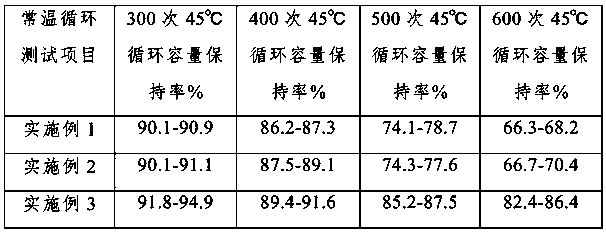

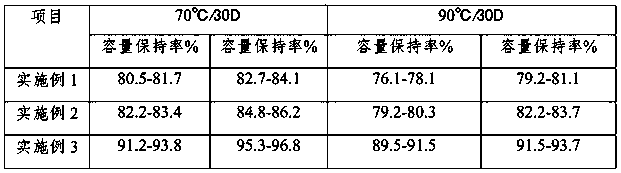

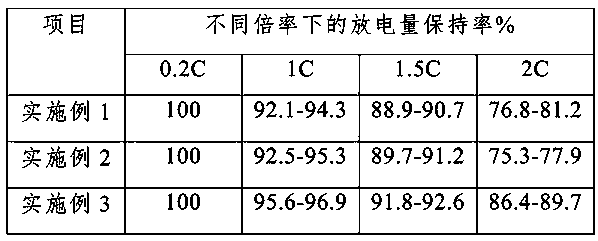

Examples

Embodiment 1

[0025] This embodiment provides a preparation method of vinyl sulfate, the preparation method is: add 100 grams of ethylene glycol and 300 grams of dichloromethane to the reaction kettle, add 200.2 grams of trimethylamine, stir and mix evenly, and add Slowly introduce (5mL / min) 181.9 grams of sulfuryl fluoride, slightly heat the reaction system to 30°C, stir and react for 18 hours, after the reaction is completed, filter to obtain 500.19 grams of organic phase containing vinyl sulfate, and distill out the disulfide under reduced pressure. Methane chloride and drying gave 191.58 g of vinyl sulfate, with a yield of 95.8%, a purity of 99.92%, a water content of 20 ppm, and an acid value of 10 ppm.

Embodiment 2

[0027] This embodiment provides a method for preparing vinyl sulfate. The preparation method is as follows: add 100 grams of ethylene glycol and 300 grams of acetone to the reaction kettle, add 342.7 grams of triethylamine, stir and mix evenly, and slowly add Pass in (4mL / min) 181.9 grams of sulfuryl fluoride, heat the reaction system to 40°C, stir and react for 24 hours, after the reaction is completed, filter to obtain 500.19 grams of organic phase containing vinyl sulfate, dichloromethane is distilled off under reduced pressure , and dried to obtain 192.18 grams of vinyl sulfate, with a yield of 96%, a purity of 99.93%, a water content of 18 ppm, and an acid value of 8 ppm.

Embodiment 3

[0029] The present embodiment provides a preparation method of vinyl sulfate. The preparation method is as follows: add 100 grams of ethylene glycol and 300 grams of acetonitrile into the reaction kettle, add 206.8 grams of tetramethylethylenediamine, stir and mix evenly, and add Slowly pour (2mL / min) 181.9 grams of sulfuryl fluoride into the solution, heat the reaction system to 60°C, stir and react for 36 hours, after the reaction is completed, filter to obtain 500.19 grams of organic phase containing vinyl sulfate, which is evaporated under reduced pressure Dichloromethane, drying to obtain vinyl sulfate 193.18 grams, yield 96.5%, purity 99.95%, water content 15ppm, acid value 6ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com