A high thermal conductivity wear-resistant self-lubricating liner and its preparation method

A self-lubricating, high thermal conductivity technology, used in braids, rolling resistance optimization, fiber processing, etc., can solve the problem of ignoring the requirements of thermal conduction and heat dissipation, and achieve lower production costs, good wear resistance and self-lubrication, and make up for impregnation. ineffective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

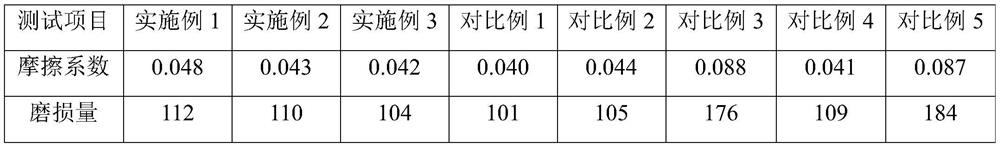

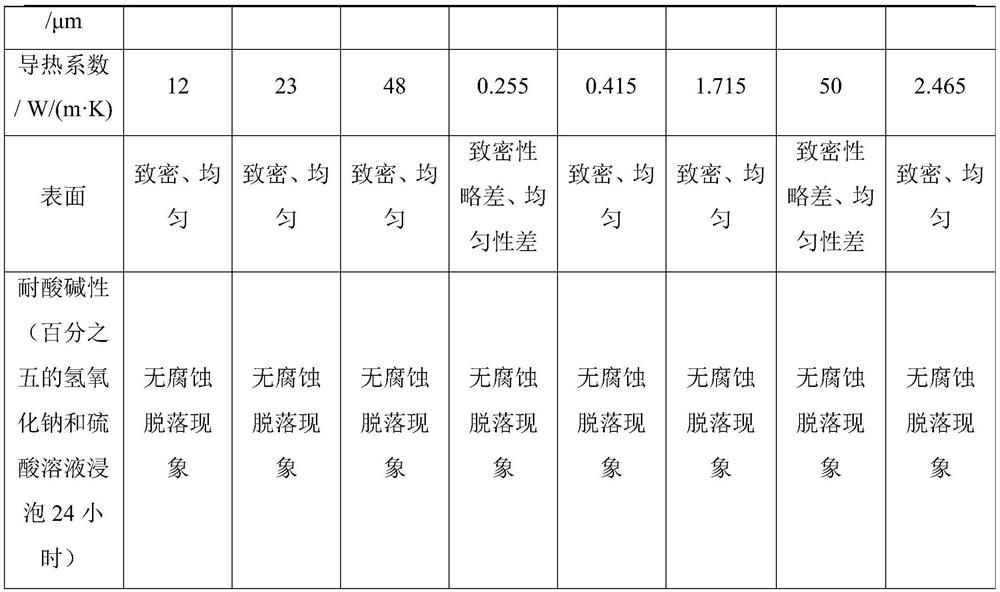

Embodiment 1

[0037] A high thermal conductivity and wear-resistant self-lubricating liner of the present invention, the high thermal conductivity and wear-resistant self-lubricating liner is obtained by immersing a fiber fabric in an immersion solution, and then hot-pressing; wherein the fiber fabric is made of the following parts by weight Weaving of components: 40 parts of polytetrafluoroethylene fiber, 30 parts of aramid 1313 fiber, 5 parts of graphite fiber, 25 parts of PA6 / 66 / 1010 / 12 quaternary copolyamide (melting point is 132°C); carbon of graphite fiber Content ≥ 99%, modulus ≥ 344Gpa. The impregnating solution is made by mixing diluent and phenolic resin in a mass ratio of 1:3, and the diluent is made by mixing absolute ethanol and ethyl acetate in a mass ratio of 1:1.

[0038] The preparation method of the high thermal conductivity wear-resistant self-lubricating liner of this embodiment comprises the following steps:

[0039] (1) Mix absolute ethanol and ethyl acetate uniformly...

Embodiment 2

[0044] A high thermal conductivity and wear-resistant self-lubricating liner of the present invention, the high thermal conductivity and wear-resistant self-lubricating liner is obtained by immersing a fiber fabric in an immersion solution, and then hot-pressing; wherein the fiber fabric is made of the following parts by weight Weaving of components: 35 parts of polytetrafluoroethylene fiber, 25 parts of aramid fiber 1313, 15 parts of graphite fiber, 25 parts of PA6 / 66 / 1010 / 12 quaternary copolyamide (melting point is 132°C); carbon of graphite fiber Content ≥ 99%, modulus ≥ 344Gpa. The impregnating solution is made by mixing diluent and phenolic resin in a mass ratio of 1:3, and the diluent is made by mixing absolute ethanol and ethyl acetate in a mass ratio of 1:1.

[0045] The preparation method of the high thermal conductivity wear-resistant self-lubricating liner of this embodiment comprises the following steps:

[0046] (1) Mix absolute ethanol and ethyl acetate uniforml...

Embodiment 3

[0051] A high thermal conductivity and wear-resistant self-lubricating liner of the present invention, the high thermal conductivity and wear-resistant self-lubricating liner is obtained by immersing a fiber fabric in an immersion solution, and then hot-pressing; wherein the fiber fabric is made of the following parts by weight Weaving of components: 30 parts of polytetrafluoroethylene fiber, 30 parts of aramid 1313 fiber, 20 parts of graphite fiber, 20 parts of PA6 / 66 / 1010 / 12 quaternary copolyamide (melting point is 132 °C); carbon of graphite fiber Content ≥ 99%, modulus ≥ 344Gpa. The impregnating solution is made by mixing diluent and phenolic resin in a mass ratio of 1:3, and the diluent is made by mixing absolute ethanol and ethyl acetate in a mass ratio of 1:1.

[0052] The preparation method of the high thermal conductivity wear-resistant self-lubricating liner of this embodiment comprises the following steps:

[0053] (1) Mix absolute ethanol and ethyl acetate uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com