Thinly-coated high-viscosity pressure-sensitive adhesive, and pressure-sensitive adhesive tape

A pressure-sensitive adhesive, high-viscosity technology, applied in the field of pressure-sensitive adhesives, can solve the problems affecting the yield rate of wireless charging module assembly, the poor actual bonding effect of nanocrystals, and the lack of bonding performance, and achieve excellent adhesion. knot effect, excellent peel force, excellent initial tack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

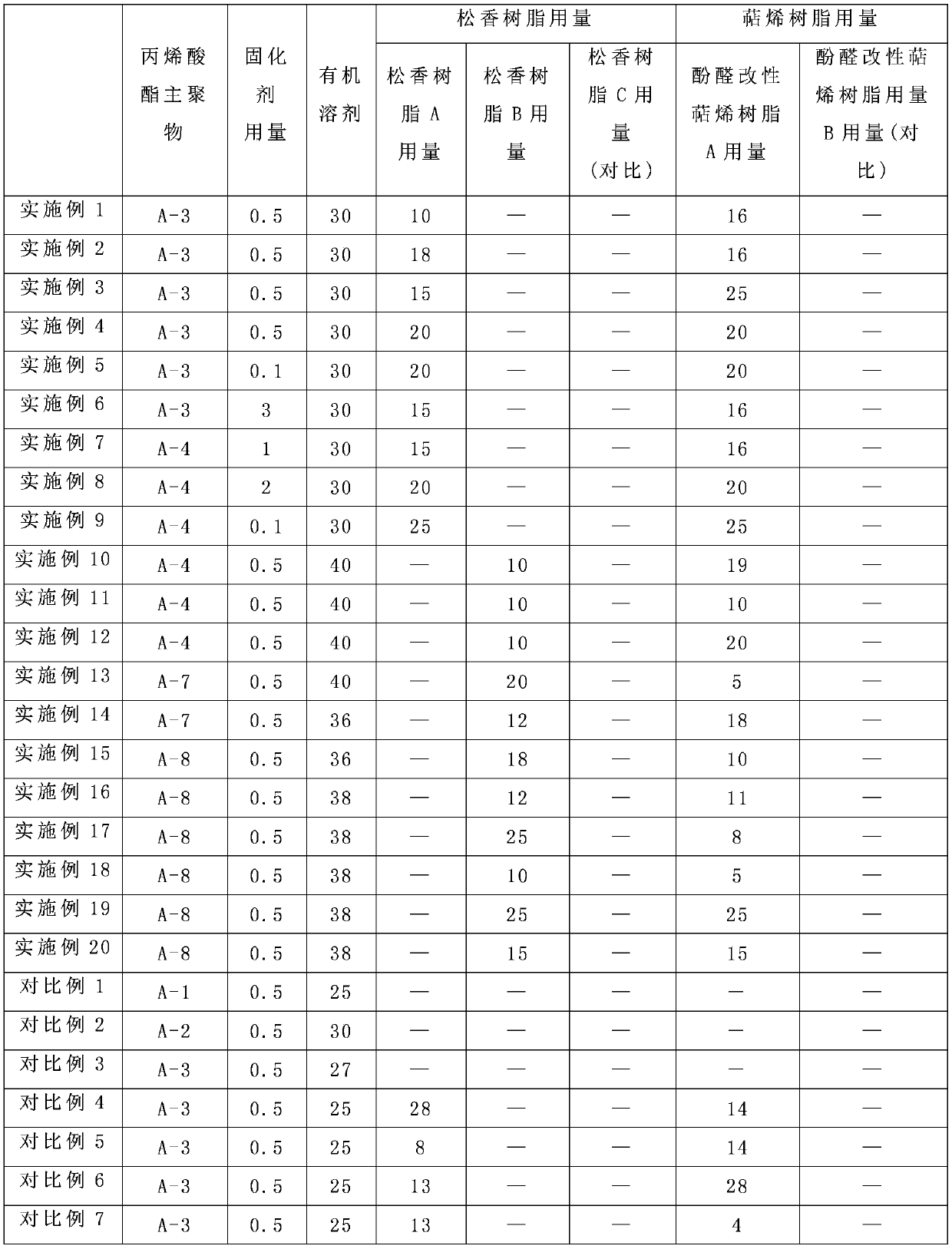

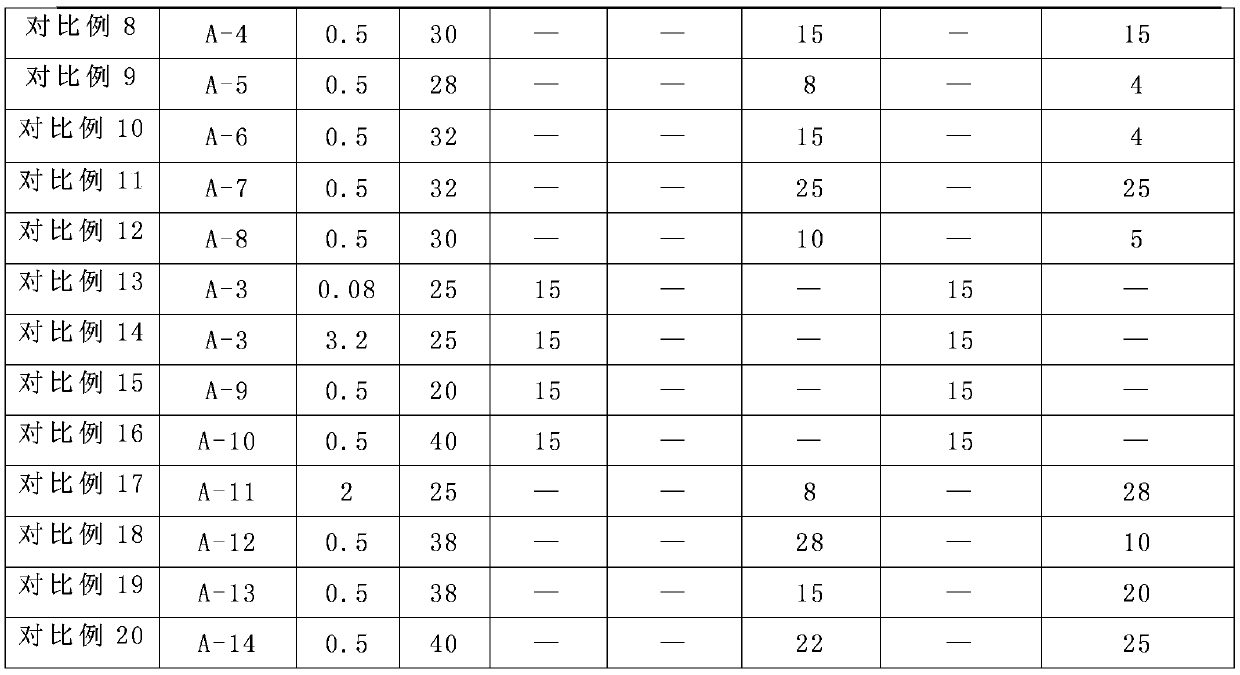

Examples

preparation example Construction

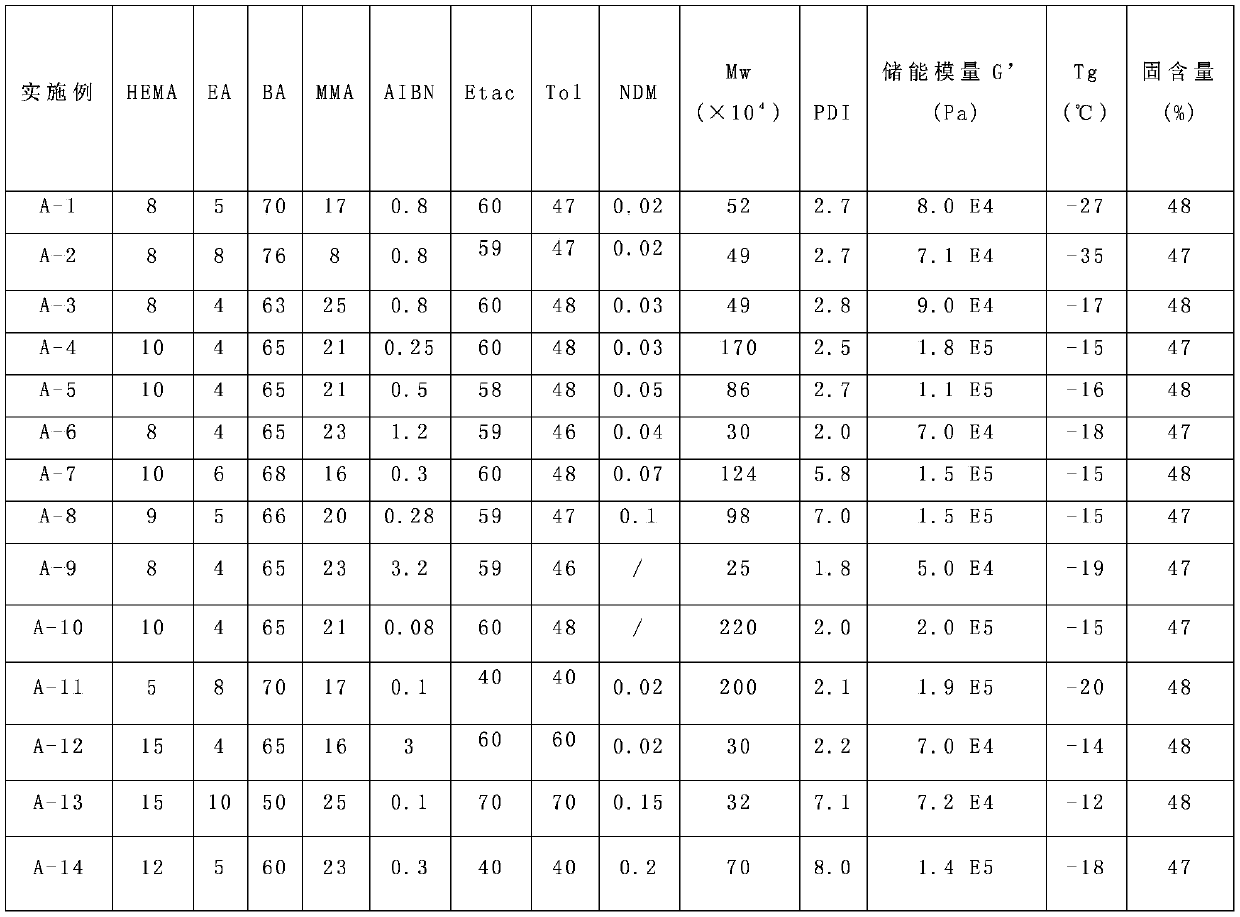

[0020] 1. Preparation of acrylate resin pulp

[0021] This example provides a preparation method of acrylate resin syrup, the specific steps are as follows: Weigh the raw materials in parts by mass, add 1 / 2 of the total mass of acrylate soft and hard monomers, 1 / 2 of the total mass of the hydroxyl-containing monomer, 1 / 3 of the total mass of the organic solvent, and 3 / 5 of the total mass of the thermal initiator, stirred and mixed under nitrogen flow for 30-60min, and then slowly dripped 1 / 3 of the total mass of the initiator 5 and 1 / 3 of the total mass of the remaining soft and hard acrylate monomers, hydroxyl-containing monomers and organic solvents, react at a temperature of 60-85°C for 8-15 hours, and finally add the remaining thermal initiator, the remaining Organic solvent and molecular weight regulator, heat preservation for 1-2 hours, make the polymerization reaction complete, and obtain acrylate resin syrup.

[0022] Specifically, in this example, the acrylate soft a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com