Device and method for removing oils in waste aluminum-based catalyst through continuous refluxing

A technology of spent catalysts and catalysts, applied in chemical instruments and methods, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., can solve problems such as high equipment requirements, large alcohol degradation, complex processes, etc., to reduce operating costs, Strong adsorption, environmental friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

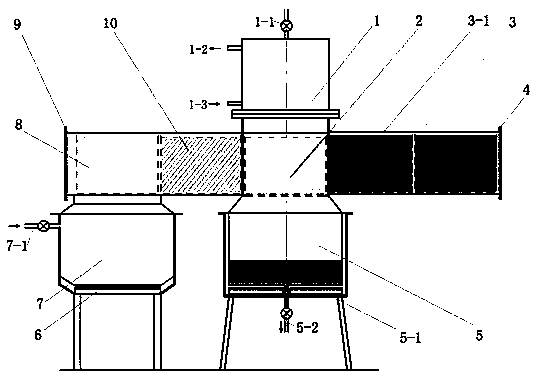

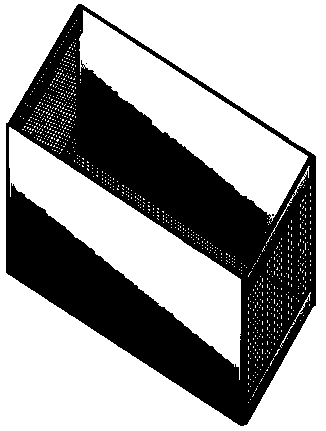

[0035] Embodiment 1: A kind of continuous reflux removes the device of oil in waste aluminum-based catalyst (see figure 1 ), including a horizontal spent catalyst deoiling treatment chamber and a screen frame 3 for containing spent catalyst; the catalyst inlet of the spent catalyst treatment chamber is provided with an openable and closable sealing door I4, and the catalyst outlet of the spent catalyst treatment chamber is provided with an openable and closable sealing door Door II9, the waste catalyst treatment chamber is divided into preheating chamber 3, backflow deoiling chamber 2, light oil initial washing chamber 10, and light oil cleaning chamber 8 from the catalyst inlet to the catalyst outlet in sequence; the backflow deoiling chamber 2 is located in the spent catalyst In the center of the processing chamber, the bottom end of the backflow deoiling chamber 2 is provided with a light oil evaporation chamber 5 communicating with the backflow deoiling chamber 2; the lowe...

Embodiment 2

[0050] Embodiment 2: In this embodiment, the waste aluminum-based catalyst contains 40.22wt% of alumina, 32.40wt% of oily matter, 2.82wt% of sulfur, and the diameter of the waste aluminum-based catalyst is 2mm;

[0051] A method for removing oil from waste aluminum-based catalysts by continuous reflux, using a device for removing oil from waste aluminum-based catalysts by continuous reflux, the specific steps are as follows:

[0052] (1) Mix light oil and waste aluminum-based catalyst evenly to obtain waste aluminum-based catalyst / light oil mixed particles; wherein the mass ratio of waste aluminum-based catalyst to light oil is 100:20;

[0053] (2) Add 180g of light oil into the light oil evaporation chamber, and put the waste aluminum-based catalyst / light oil mixed particles in step (1) into two spent catalyst screen frames, each containing 450g of waste aluminum-based catalyst ; Then put two net frames containing spent catalyst into the preheating cavity from the sealed door...

Embodiment 3

[0057]Embodiment 3: In this embodiment, the waste aluminum-based catalyst contains 54.26wt% of alumina, 15.00wt% of oily matter, 2.00wt% of sulfur, and the diameter of the waste aluminum-based catalyst is 2mm;

[0058] A method for removing oil from waste aluminum-based catalysts by continuous reflux, using a device for removing oil from waste aluminum-based catalysts by continuous reflux, the specific steps are as follows:

[0059] (1) Mix light oil and waste aluminum-based catalyst evenly to obtain waste aluminum-based catalyst / light oil mixed particles; wherein the mass ratio of waste aluminum-based catalyst to light oil is 100:10;

[0060] (2) Add 180g of light oil to the light oil evaporation chamber, and put the waste aluminum-based catalyst / light oil mixed particles in step (1) into two screen frames containing waste catalyst, and each waste catalyst screen frame contains 450g of waste aluminum-based catalyst ; Then put two spent catalyst screen frames into the preheati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com