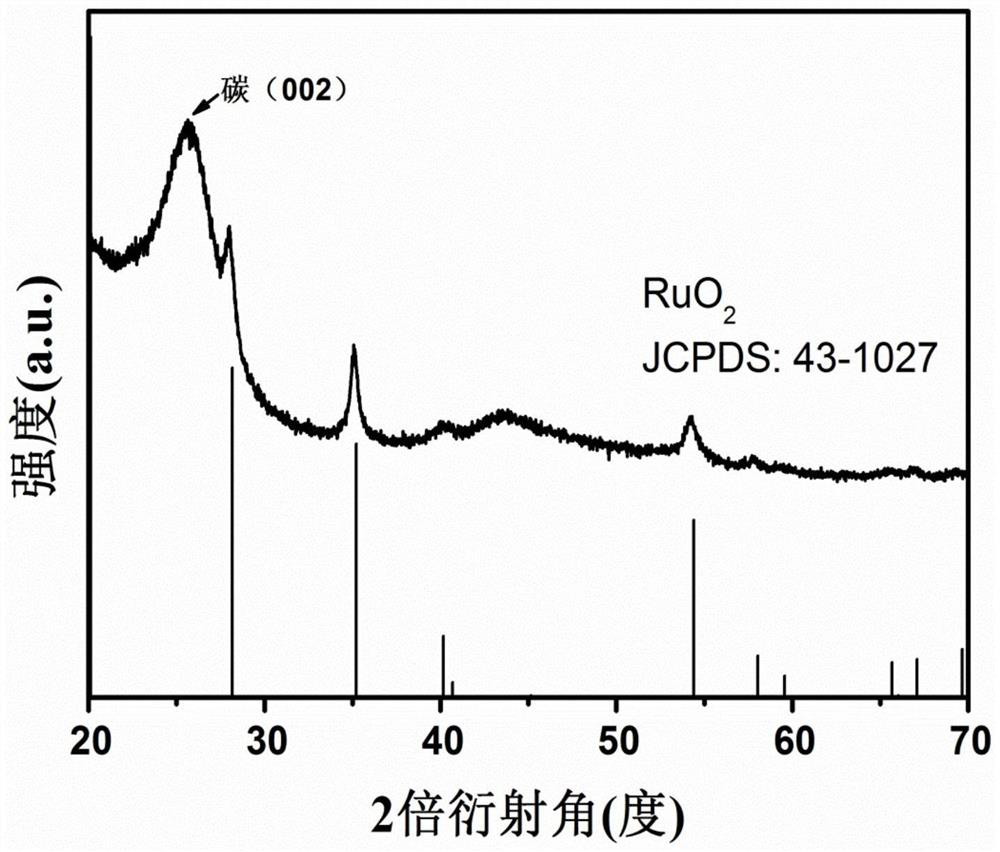

A kind of preparation method of efficient and stable ruthenium dioxide-based acidic oxygen evolution electrocatalyst

A ruthenium dioxide-based acid and electrocatalyst technology, applied in electrodes, electrolysis components, electrolysis processes, etc., can solve the problems of inability to meet the requirements of large-scale industrial production, difficulty in fully utilizing ruthenium precursors, and increase in production processes, and achieve excellent results. Stability, good stability and the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

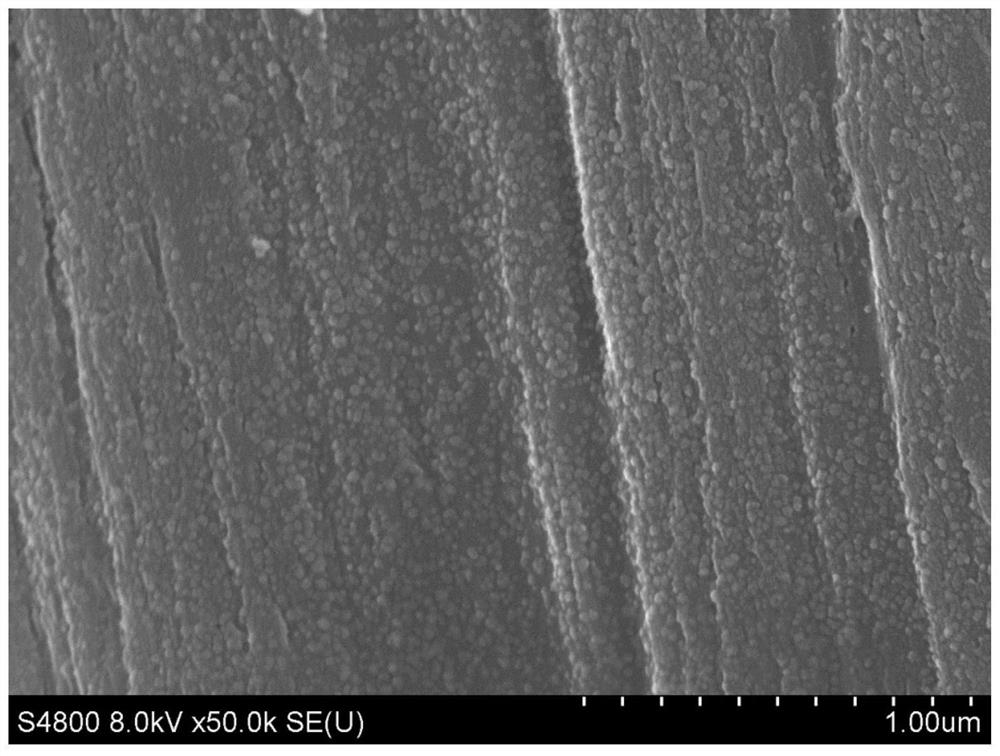

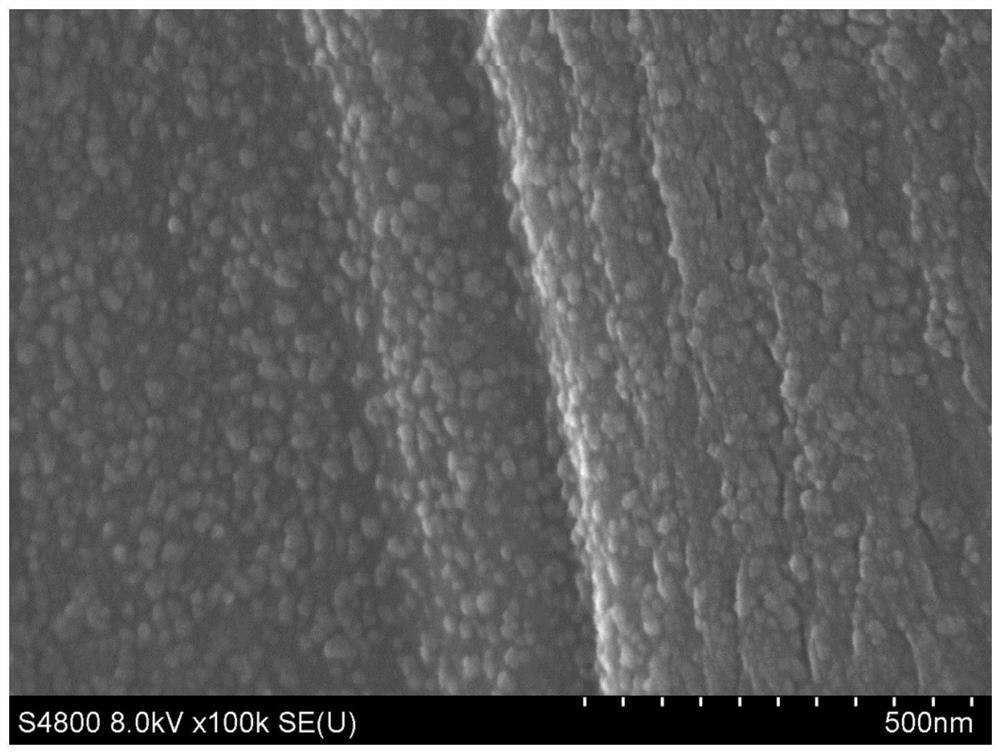

Embodiment 1

[0029] In this example, the preparation of the acidic oxygen evolution electrocatalyst is as follows:

[0030] (1) Substrate pretreatment

[0031] Cut the carbon cloth base to 1 cm wide and 2 cm long, and place it in absolute ethanol for ultrasonic treatment. Then, the carbon cloth was taken out and put into a polytetrafluoroethylene reactor containing a nitric acid solution with a concentration of about 68% by mass, and the reactor was placed in an oven at 120° C. for 2 hours to keep warm. Afterwards, the resulting carbon cloth was washed with deionized water and dried at 80 °C.

[0032] (2) Ruthenium chloride precursor coating

[0033] Dissolve 1.56g of ruthenium trichloride hydrate and 0.25g of polyvinylpyrrolidone K-30 (PVP-K30) in 10ml of N,N-dimethylformamide (DMF), and obtain evenly mixed ruthenium chloride by magnetic stirring precursor solution. Immerse the carbon cloth treated in step (1) in the ruthenium chloride precursor solution for 1 second, take it out quic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com