A high-temperature resistant ultra-short cavity distributed reflection single-frequency fiber laser and its manufacturing method

A fiber laser and distributed reflection technology, used in lasers, laser parts, phonon exciters, etc., can solve problems such as differences in refractive index and temperature resistance, reduce cavity length, ensure temperature resistance, and increase complexity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

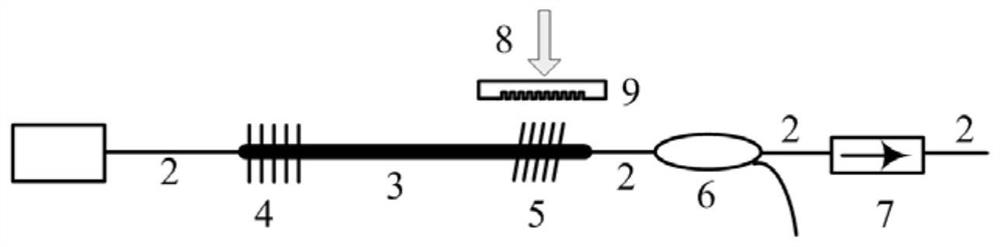

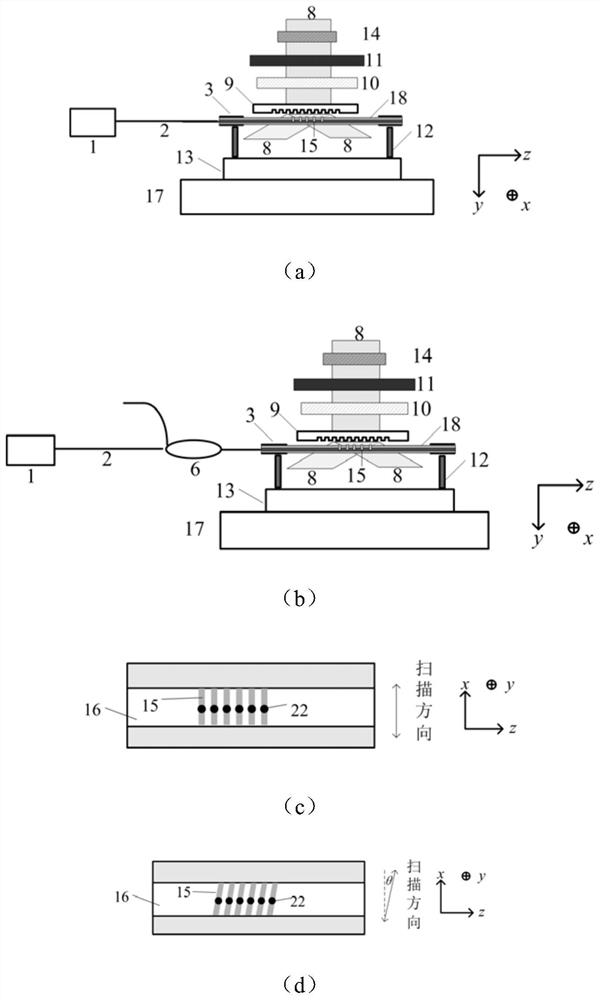

[0056] This embodiment takes the preparation of an ultra-short cavity erbium-doped fiber distributed reflection fiber laser as an example, and the manufacturing steps and laser structure are as follows image 3 As shown, the details are as follows:

[0057] Material: Erbium-doped fiber Liekki Er80-8 / 125, mask period 2142nm, 976nm single-mode semiconductor laser pump source;

[0058] (1) The pigtail 2 of the laser pump source 1 is fused together with a section of erbium-doped optical fiber, as image 3 As shown in (a).

[0059] (2) Strip the active optical fiber coating near the fusion point by about 2 cm with a wire stripper, and fix the active optical fiber stripped of the coating on the three-dimensional piezoelectric nano-displacement stage 13 with an optical fiber clamp 12, such as image 3 Shown in (b).

[0060] (3) The femtosecond laser 8 is incident on the cylindrical lens 10 through the optical shutter 14 and the variable attenuator 11. After being focused by the cy...

Embodiment 2

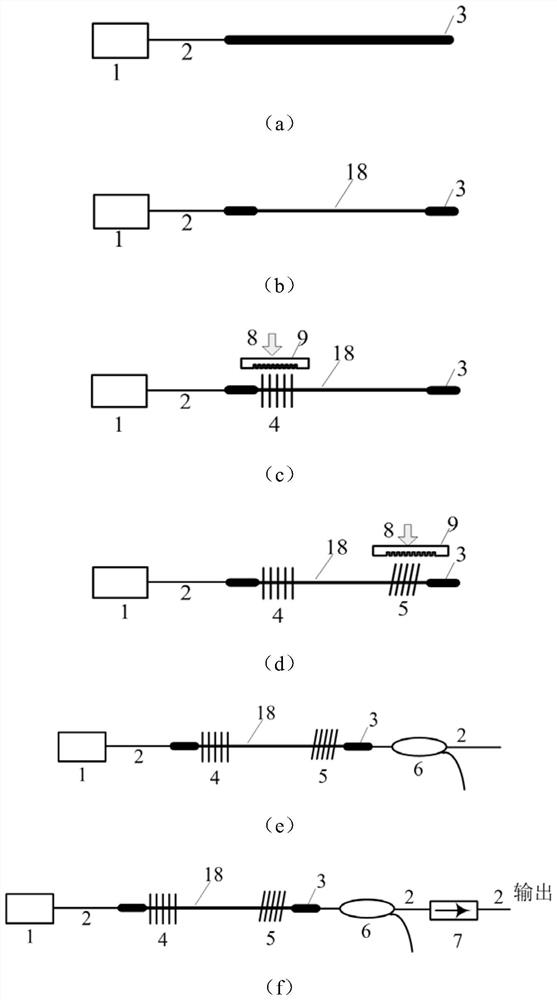

[0066] This embodiment takes the fabrication of a short-cavity distributed reflection fiber laser on an ytterbium-doped active fiber as an example, such as Figure 5 As shown, the details are as follows:

[0067] Material: Ytterbium-doped active fiber SM-YSF-HI, mask period 1485nm, 976nm single-mode semiconductor laser pump source;

[0068] (1) The pigtail 2 of the laser pumping source 1 is fused together with the pump end of the wavelength division multiplexer 6, and the common end of the wavelength division multiplexer 6 is fused with a section of ytterbium-doped active optical fiber with a length of 4 cm. See Figure 5 Medium (a)

[0069] (2) Strip the active optical fiber coating near the fusion point by about 2 cm with wire strippers, and fix the active optical fiber stripped of the coating on the three-dimensional piezoelectric nano-displacement stage 13 with an optical fiber clamp 12, see Figure 5 In (b).

[0070] (3) The femtosecond laser 8 is incident on the cylin...

Embodiment 3

[0075] This embodiment takes the example of making a short-cavity distributed reflective fiber laser on an erbium / ytterbium co-doped active fiber, as follows:

[0076] Material: Erbium / ytterbium co-doped active fiber EYDF-6 / 125-HE, mask period 2142nm, 976 nm single-mode semiconductor laser pump source,;

[0077] (1) The pigtail 2 of the laser pump source 1 is fused together with the pump end of the wavelength division multiplexer 6, and the common end of the wavelength division multiplexer 6 is co-doped with an erbium / ytterbium active fiber with a length of 4 cm, See Figure 5 Medium (a)

[0078] (2) Use wire strippers to strip off the erbium / ytterbium co-doped active fiber coating near the fusion point by about 2 cm, and fix the stripped active fiber on the three-dimensional piezoelectric nano-displacement stage with the fiber clamp 12 13, see Figure 5 Middle (b).

[0079] (3) The femtosecond laser 8 is incident on the cylindrical lens 10 through the optical shutter 14 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com