Cascade pumping optical fiber laser based on double-ended output oscillators

A fiber laser and cascade pumping technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of low laser efficiency and achieve the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

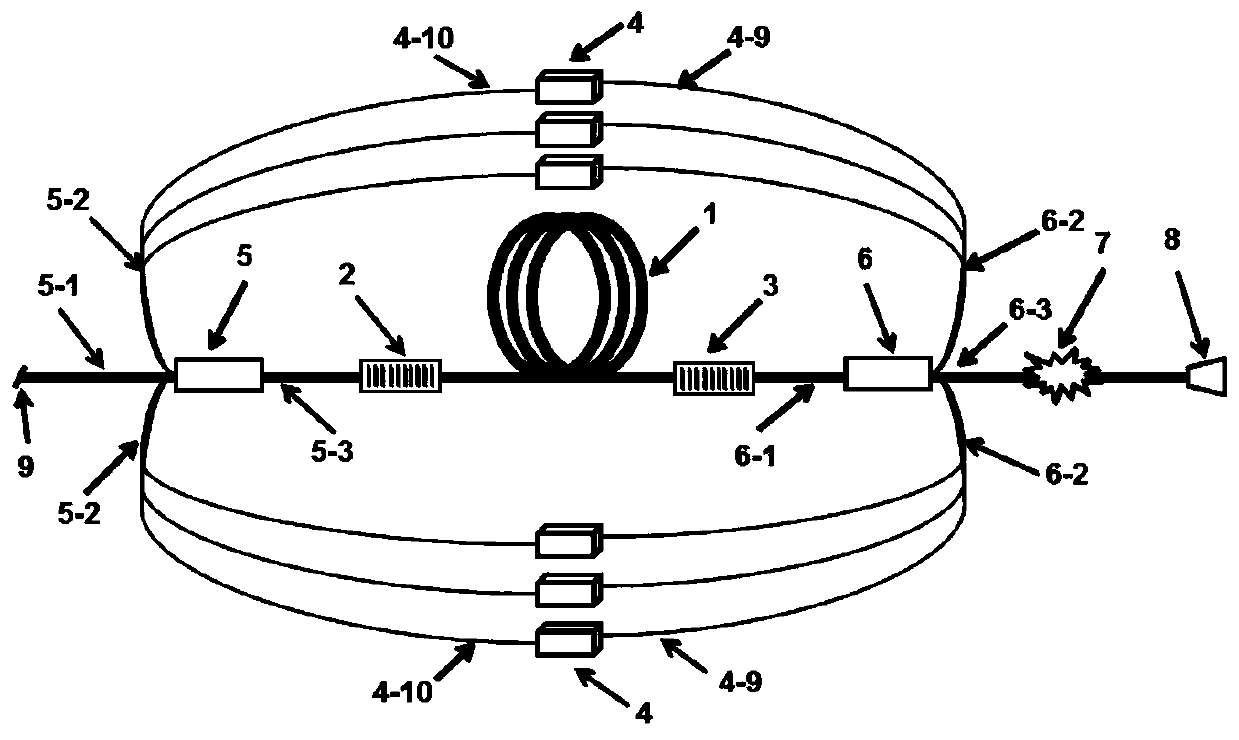

[0032] This example presents a cascaded pumped fiber laser based on a double-ended output oscillator, and its structure refers to figure 1 , the cascaded pump fiber laser includes a laser resonator, a forward pump signal combiner 5, a backward pump signal combiner 6, a cladding optical filter 7, a fiber end cap 8 and at least two double output laser oscillator 4. Both the forward pump signal combiner 5 and the backward pump signal combiner 6 in this embodiment can bidirectionally transmit signal laser light.

[0033] The laser resonator of this embodiment includes a high-reflection fiber grating 2, a gain fiber 1 and a low-reflection fiber grating 3 which are sequentially welded by optical fibers. Wherein, the operating wavelength of the gain fiber 1, the high reflection fiber grating 2 and the low reflection fiber grating 3 in the ytterbium-doped fiber laser is 1050-1150 nm. The gain fiber 1 has a double-clad or triple-clad structure. Among them, the core is doped with rar...

Embodiment 2

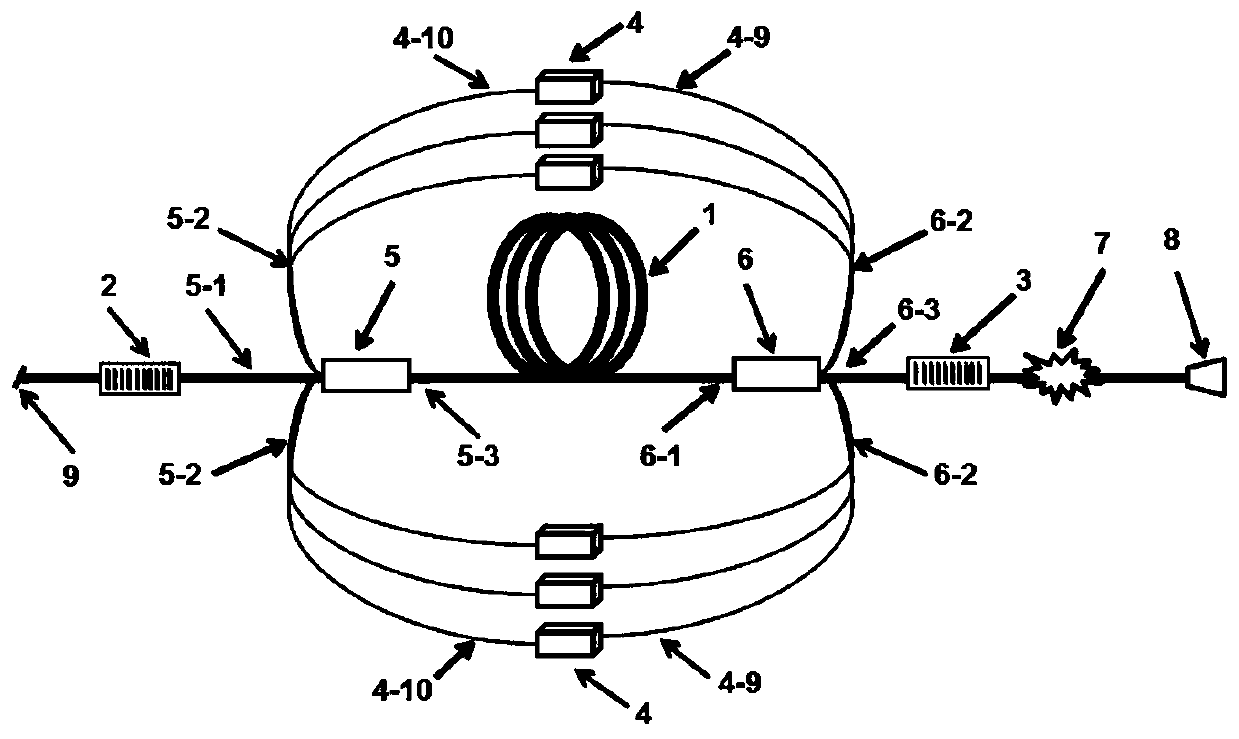

[0042] The structure of this embodiment is basically the same as that of Embodiment 1, except that the connection relationship between the laser resonator and the forward pump signal combiner 5 and the backward pump signal combiner 6 is different, as follows:

[0043] Each forward output optical fiber 4-10 is connected to the corresponding first pump injection arm 5-2; each backward output optical fiber 4-9 is connected to the corresponding second pump injection arm 6-2; the first signal input The arm 5-1 is connected to one end of the high-reflection fiber grating 2, and the other end of the high-reflection fiber grating 2 is welded to the power transmission fiber 9 at an angle of 8 degrees, which can avoid the parasitic oscillation of the laser caused by other optical feedback in the non-laser band. The first pump signal output arm 5-3 is connected to one end of the gain fiber 1 through the pump signal energy transmission fiber; the other end of the gain fiber 1 is connected ...

Embodiment 3

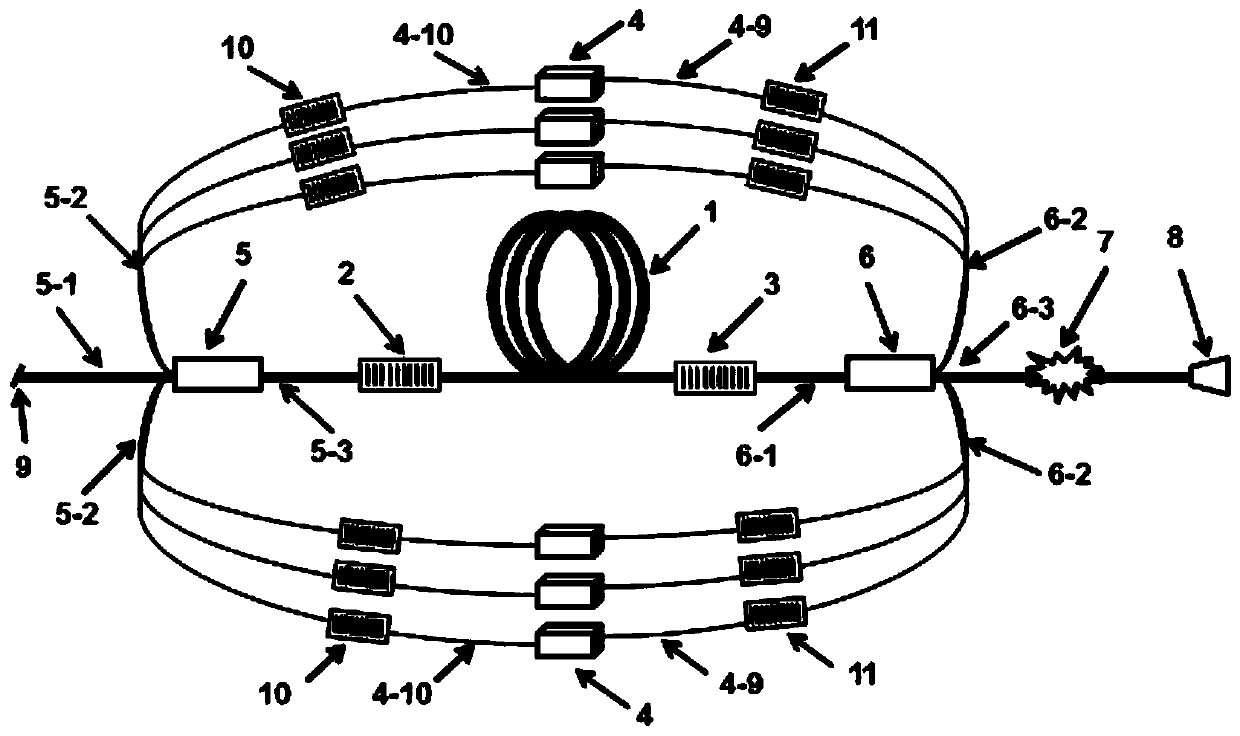

[0047] The structure of this embodiment is basically the same as that of Embodiment 1, except that: a first tilted grating 10 is arranged between each forward output optical fiber 4-10 and the corresponding first pump injection arm 5-2; A second tilted grating 11 is arranged between each backward output optical fiber 4-9 and the corresponding second pump injection arm 6-2, refer to image 3 . Both the first tilted grating 10 and the second tilted grating 11 transmit the working wavelength (1000nm-1040nm) of the double-ended output laser oscillator 4, and reflect the working wavelength (1050-1150nm) of the cascaded pump fiber laser, so as to Avoid long-wavelength laser injection causing self-excitation of the double-ended output laser oscillator 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com