Hydrocracking catalyst, preparation method and applications thereof

A hydrocracking and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems that cannot meet actual needs and product quality is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The preparation method of the carrier is well known to those skilled in the art, and the present disclosure has no special limitation. For example, the method may further include: mixing phosphorus-containing Y-type molecular sieves, Beta molecular sieves, heat-resistant inorganic oxides, solvents and optional additives, and then molding and drying to obtain the carrier. The forming method can adopt various conventional methods, such as tablet forming, rolling ball forming or extrusion forming and the like. The solvent is a common solvent in the catalyst molding process. When the method of extrusion molding is adopted, it is preferable to add an appropriate amount of additives to facilitate molding.

[0064] Optionally, the preparation method of the carrier includes: mixing phosphorus-containing Y-type molecular sieves, Beta molecular sieves, heat-resistant inorganic oxides, peptizers, and optional lubricants, and then forming, drying, and calcining to obtain the carri...

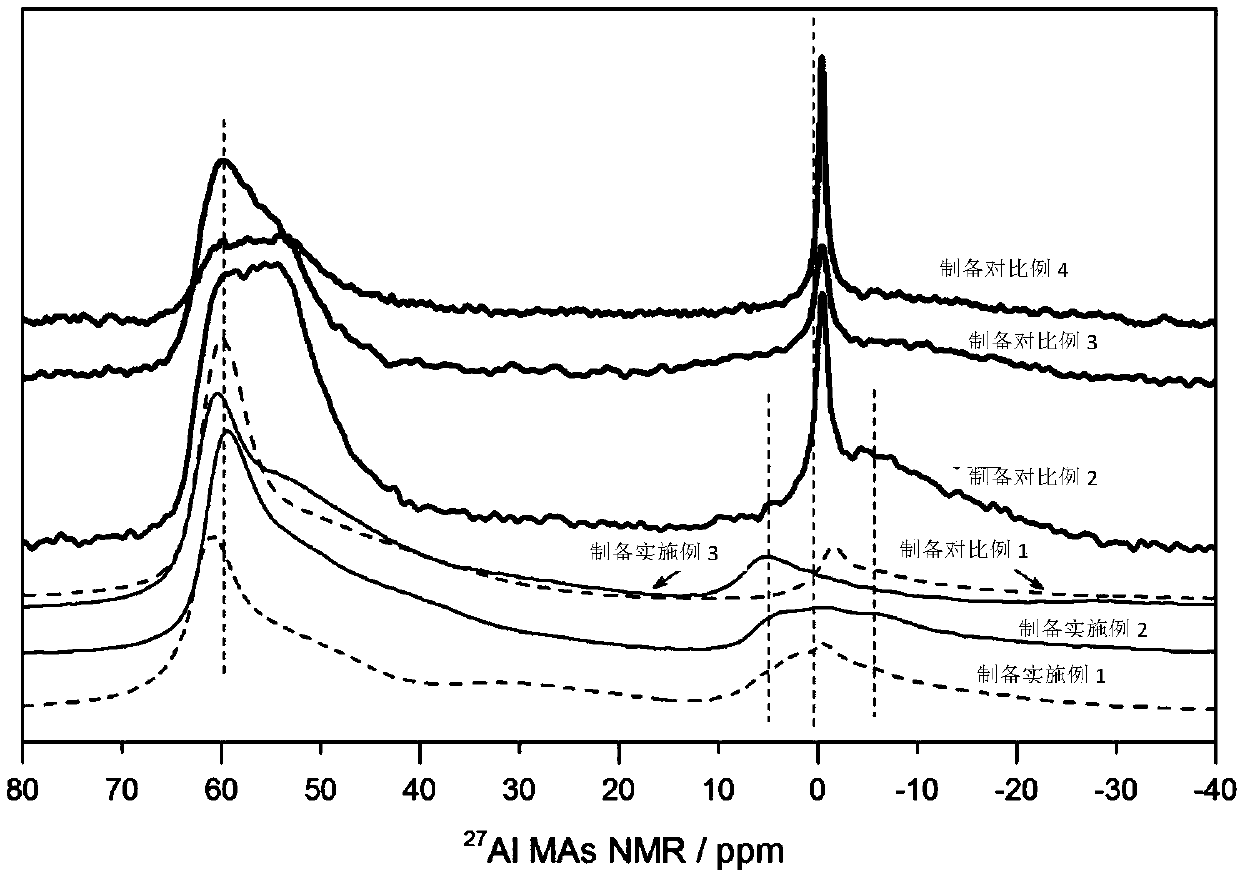

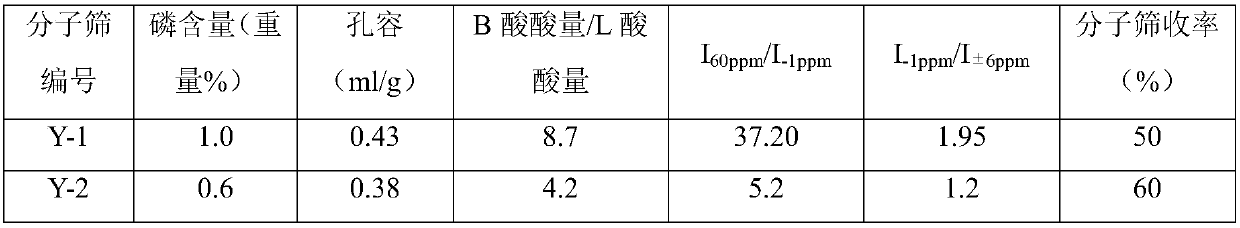

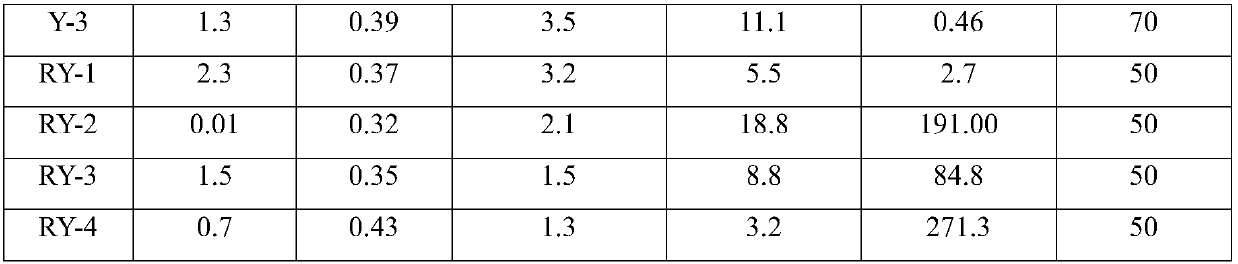

preparation Embodiment 1

[0086] Get NaY molecular sieve (produced by Sinopec Catalyst Changling Branch Company, trade name NaY, unit cell constant is 2.468nm, specific surface area is 680m 2 / g, the pore volume is 0.30ml / g, Na 2 O content is 13.0 wt%, Al 2 o 3 content is 22% by weight) 300g, add 2.0mol / L of (NH 4 ) 2 HPO 4 Aqueous solution, beating, the total amount of water used is 1000ml, filter, repeat the above process for the obtained filter cake three times, and then dry at 100°C for 1 hour to obtain the phosphorus-containing molecular sieve raw material, and the unit cell constant of the phosphorus-containing molecular sieve raw material is measured to be 2.468nm , the specific surface area is 590m 2 / g, the pore volume is 0.37ml / g, P 2 o 5 The content is 4.8% by weight, Na 2 The O content is 3.5% by weight.

[0087] Take 100 g of the above-mentioned phosphorus-containing molecular sieve raw material and put it into a hydrothermal treatment device, feed 100% water vapor, raise the temp...

preparation Embodiment 2

[0091] Take PSRY molecular sieve (Sinopec Catalyst Changling Branch, produced by the company, trade name PSRY, unit cell constant is 2.456nm, specific surface area is 620m 2 / g, the pore volume is 0.39ml / g, Na 2 O content is 2.2% by weight, P 2 o 5 The content is 1.5% by weight, Al 2 o 3 The content is 18% by weight) 300g, add deionized water for beating, the total amount of water is 1000ml, filter, and dry at 70°C for 2h to obtain a phosphorus-containing molecular sieve raw material with a water content of 35% by weight.

[0092] The above-mentioned phosphorus-containing molecular sieve raw material is crushed, sieved into 5-20 meshes (wherein 1mm~500mm particles account for 70% by weight of the total weight of the phosphorus-containing molecular sieve raw material), put into a hydrothermal treatment device, feed 100% steam, and heat up to 580°C, the internal pressure of the control device is 0.4MPa, constant hydrothermal treatment for 2 hours, and then the molecular siev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell constant | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com