System and method for treating ammonia-nitrogen wastewater

A technology of ammonia nitrogen wastewater and treatment system, applied in the field of pollutant treatment, can solve the problems of low biological treatment efficiency, unstable treatment effect, difficult organic wastewater treatment, etc., achieve high pollutant removal rate and reduce the content of nitrogen oxides , The effect of reducing the burden on the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

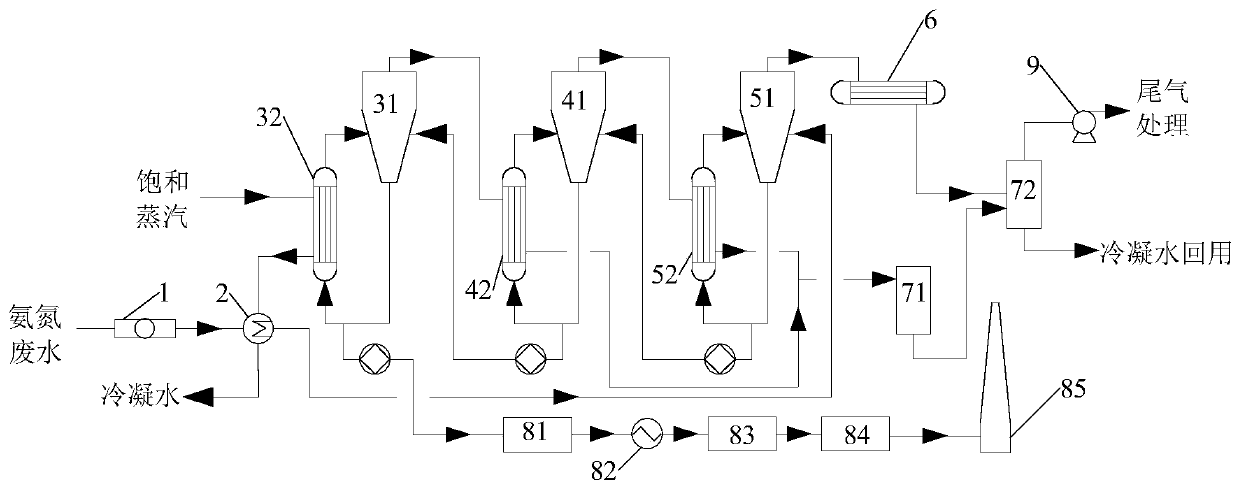

[0070] This embodiment provides an ammonia nitrogen wastewater treatment system, the structural diagram of the ammonia nitrogen wastewater treatment system is as follows figure 1 As shown, it includes: a filter device 1, a preheating unit 2, a three-effect countercurrent evaporator, a gas-liquid separation unit and a concentrated liquid combustion unit.

[0071] The discharge port of the preheating unit 2 is connected to the feed port of the three-effect evaporator 51 in the three-effect countercurrent evaporator, and the condensate outlet of the three-effect evaporator 51 in the three-effect countercurrent evaporator is connected to the gas-liquid separation unit , the liquid outlet of the first-effect evaporator 31 in the three-effect countercurrent evaporator is connected with the concentrated liquid combustion unit through a jacketed pipe.

[0072] The concentrated liquid combustion unit includes a direct combustion furnace 81 , a heat exchanger 82 , an SCR reactor 83 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com