Method for preparing methyl heptenone

A technology of methyl heptenone and methyl, which is applied in the field of organic synthesis, can solve the problems of difficult product purification, many wastes, and complicated side reactions, and achieve the effect of high atom utilization rate, less wastes, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

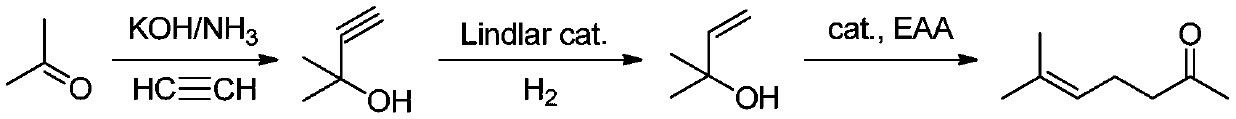

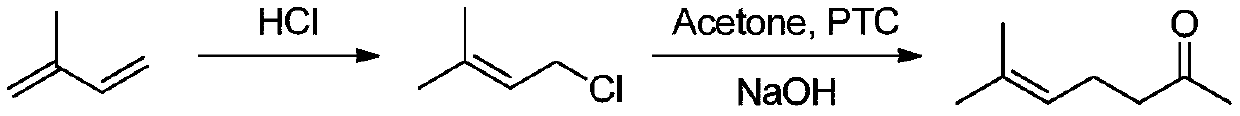

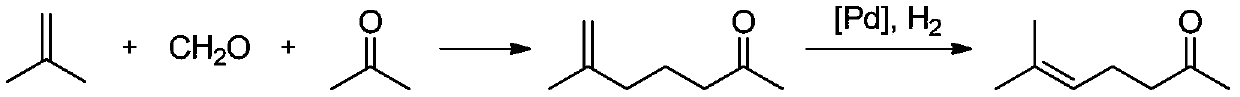

Method used

Image

Examples

Embodiment 1

[0053] Add anhydrous lithium hydroxide (122.2mg, 5mmol) in the autoclave of 1000mL, after replacing three times with high-purity nitrogen, charge the nitrogen of 0.4MPa in the reaction kettle; In the glove box, [Rh(COD) 2 ]OTf (94.62mg, 0.2mmol), 3-methyl-2-butene-1-alcohol (87.0g, 1mol) and acetone (348.5g, 6mol) were mixed, and under nitrogen atmosphere, the above-mentioned mixture was pumped Add it into the autoclave, turn on the heating and stirring device of the reactor, raise the temperature to 80°C and keep it warm for 4 hours, the conversion rate of the raw material 3-methyl-2-buten-1-ol is >99% according to GC analysis, and the reaction is terminated .

[0054] After the reaction, the reaction liquid was lowered to room temperature, excess acetone and reaction water were removed by distillation under reduced pressure, and then further distillation under reduced pressure was performed to obtain a light yellow transparent liquid product, which was characterized by NMR a...

Embodiment 2-7

[0057] When carrying out embodiment 2-7, by rhodium catalyst by [Rh(COD) 2 ] OTf is replaced by other metal rhodium catalysts of an equivalent amount, and other conditions are constant.

Embodiment 8-15

[0059] When carrying out embodiment 8-13, metal rhodium catalyst is [Rh(COD) 2 ] OTf, the alkali is replaced by other types of alkali by lithium hydroxide, the consumption of acetone is 5-20eq. (the consumption of acetone is 20eq. -2-buten-1-alcohol addition is 0.25mol).

[0060] When carrying out embodiment 14-15, metallic rhodium catalyst is [Rh(COD) 2 ] OTf, the base is lithium hydroxide, the consumption of acetone is 4eq and 6eq, and other conditions remain unchanged.

[0061]

[0062] Table 2 embodiment 1-15 reaction result

[0063] Numbering Reaction time reaction pressure Conversion rates / % selectivity / % Example 1 4h 0.6MPa 99.63 97.29 Example 2 4h 0.6Mpa 98.79 96.11 Example 3 4h 0.6MPa 98.99 97.43 Example 4 4h 0.6MPa 97.33 95.13 Example 5 4h 0.6MPa 98.65 94.36 Example 6 4h 0.6MPa 95.99 95.78 Example 7 4h 0.6MPa 99.13 97.23 Example 8 6h 1.0MPa 98.56 98.13 Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com