Device and method for recycling trichloroethane in production of sucralose

A technology of trichloroethane and sucralose, which is applied in the preparation of sugar derivatives, sugar derivatives, and sugar derivatives, etc., can solve the problems of inability to recycle dilute DMF in wastewater, loss of recycling value, and complex wastewater components. , to achieve the effect of solving the large amount of waste water, reducing the consumption and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

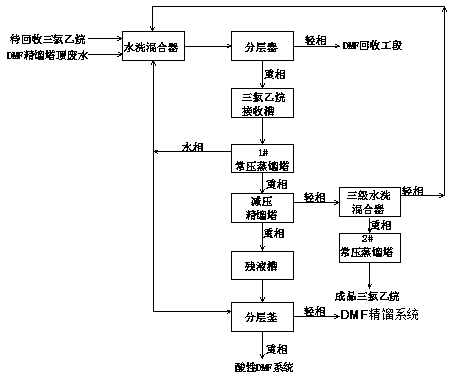

[0021] (1). The trichloroethane to be recovered in the reservoir area and the waste water from the top of the DMF rectification tower are sent to the water washing mixer in a volume ratio of 4:1, and after being fully mixed, enter the stratifier and stand for 2 minutes to stratify. The obtained light phase (water phase) is sent to the DMF recovery section; the obtained heavy phase (containing trichloroethane) is sent to the trichloroethane receiving tank through pipelines;

[0022] (2). Then send trichloroethane into 1# atmospheric distillation tower at 4000~8000L / h, raise the temperature to 116℃, and return part of the water phase from the top of the tower to the washing mixer at 800L / h Apply mechanically, and all the rest are sent to the stratified kettle for water replenishment, and the heavy phase (trichloroethane phase) from the bottom of the tower enters the vacuum distillation tower;

[0023] (3). Control the vacuum degree of the vacuum rectification tower at -0.09MPa a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com