Low-smoke halogen-free flame-retardant polyolefin electric wire material for B1-grade power distribution wires, and preparation method thereof

A technology for laying wires and polyolefins, applied in the field of wire materials, to achieve the effects of less personal and air pollution, improved compatibility, and less smoke from combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Wherein, the preparation method of the first magnesium hydroxide comprises the following steps: dispersing magnesium hydroxide in ethanol, then adding an anionic surfactant whose mass is 2% of the mass of magnesium hydroxide, stirring at 70°C After reacting for 7 hours, the ethanol was removed by rotary evaporation.

[0030] Wherein, the preparation method of the second magnesium hydroxide comprises the following steps: dispersing magnesium hydroxide in ethanol, and then adding a titanate coupling agent whose mass is 2% of the mass of magnesium hydroxide, at 70°C The reaction was stirred for 7 hours, and then the ethanol was removed by rotary evaporation.

[0031] The anionic surfactant is at least one of sodium dodecylbenzenesulfonate, sodium fatty alcohol ether sulfate, and sodium N-lauroyl sarcosinate, purchased from Guangzhou Naying Chemical; the titanate coupling The agent is isopropyl dioleate acyloxy (dioctyl phosphate acyloxy) titanate, isopropyl tris (dioctyl ...

Embodiment 1

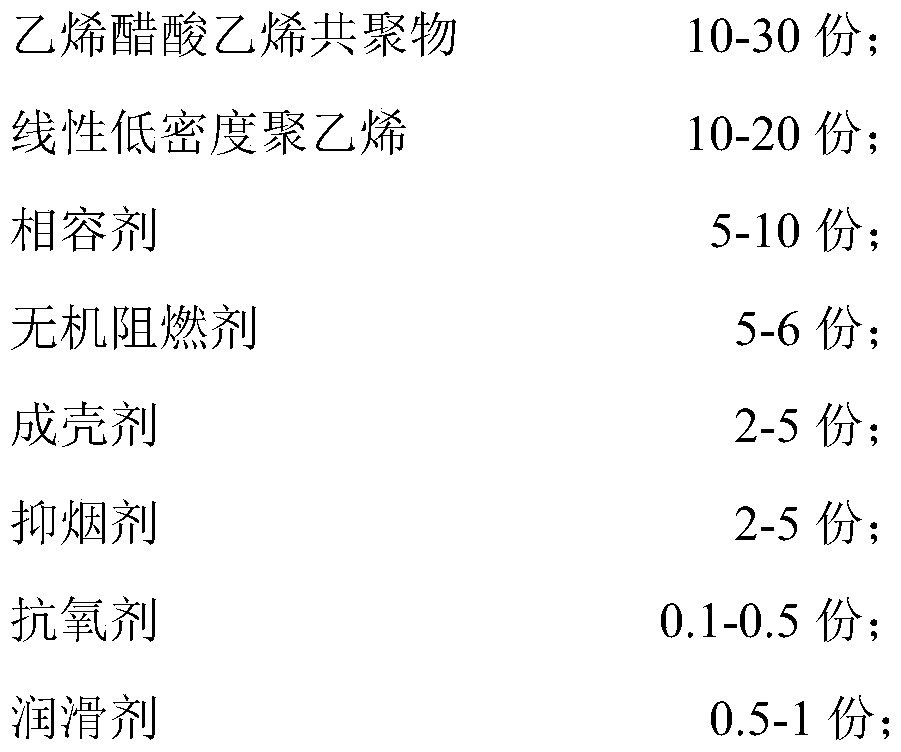

[0036] Embodiment 1 provides a low-smoke, halogen-free, flame-retardant polyolefin wire material for B1 level wiring, including the following components in parts by weight:

[0037]

[0038]

[0039] Wherein the inorganic flame retardant includes the first magnesium hydroxide surface treated with sodium dodecylbenzene sulfonate, the hydrogen oxidized The second magnesium hydroxide formed by surface activation of magnesium; the ratio of parts by weight of the first magnesium hydroxide to the second magnesium hydroxide is 1:1.

[0040] The preparation method of the low-smoke, halogen-free and flame-retardant polyolefin wire material for B1-level wiring of the present invention comprises the following steps: adding weighed ethylene-vinyl acetate copolymer, linear low-density polyethylene, compatibilizer, inorganic resistive Combustion agent, shell forming agent, smoke suppressant, antioxidant and lubricant are mixed at high speed, mixed evenly, heated and banburyed, and then ...

Embodiment 2

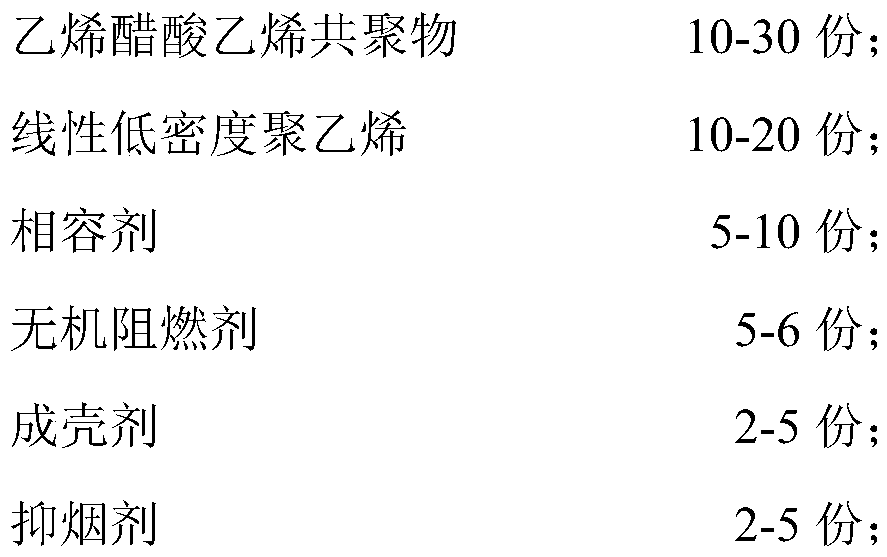

[0042] Example 2 provides a low-smoke, halogen-free, flame-retardant polyolefin wire material for B1-grade electrical wiring. Its formula and preparation method are basically the same as those in Example 1, except that it includes the following components in parts by weight:

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com