Detection method and system for detecting bonding defects inside composite insulator

A technology for composite insulators and detection methods, which is applied in the field of detection of internal bonding defects of composite insulators, can solve problems such as the influence of the external insulation surface of composite insulators, false detection of detection results, missed detection, and greater influence of subjective factors, etc., to achieve good detection Effect, intuitive imaging, intuitive detection of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

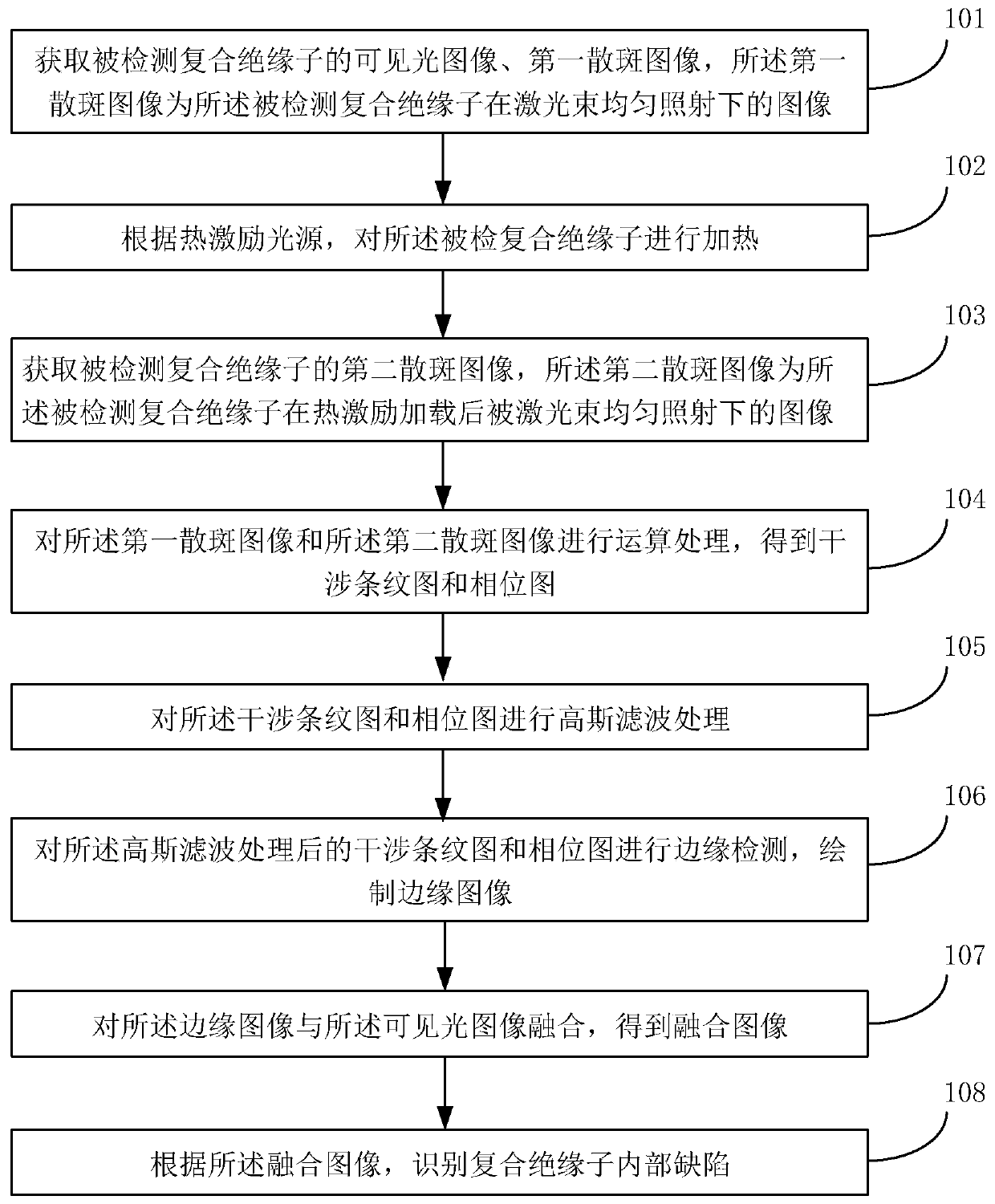

[0055] An embodiment of the present invention provides a detection method for internal bonding defects of composite insulators, which is used in the technical field of power equipment detection. figure 1 Said, the detection method of the internal bonding defect of the composite insulator includes the following steps:

[0056] 101. Acquire a visible light image and a first speckle image of the detected composite insulator, where the first speckle image is an image of the detected composite insulator under uniform laser beam irradiation;

[0057] Specifically, the visible light image is a clear image taken by the detected composite insulator under normal illumination;

[0058] The first speckle image is a dislocation speckle interference image, and the laser beam is uniformly irradiated on the surface of the composite insulator to be detected, and the diffusely reflected single beam dislocation is divided into two beams with the same amplitude, forming two mutual dislocation sca...

Embodiment 2

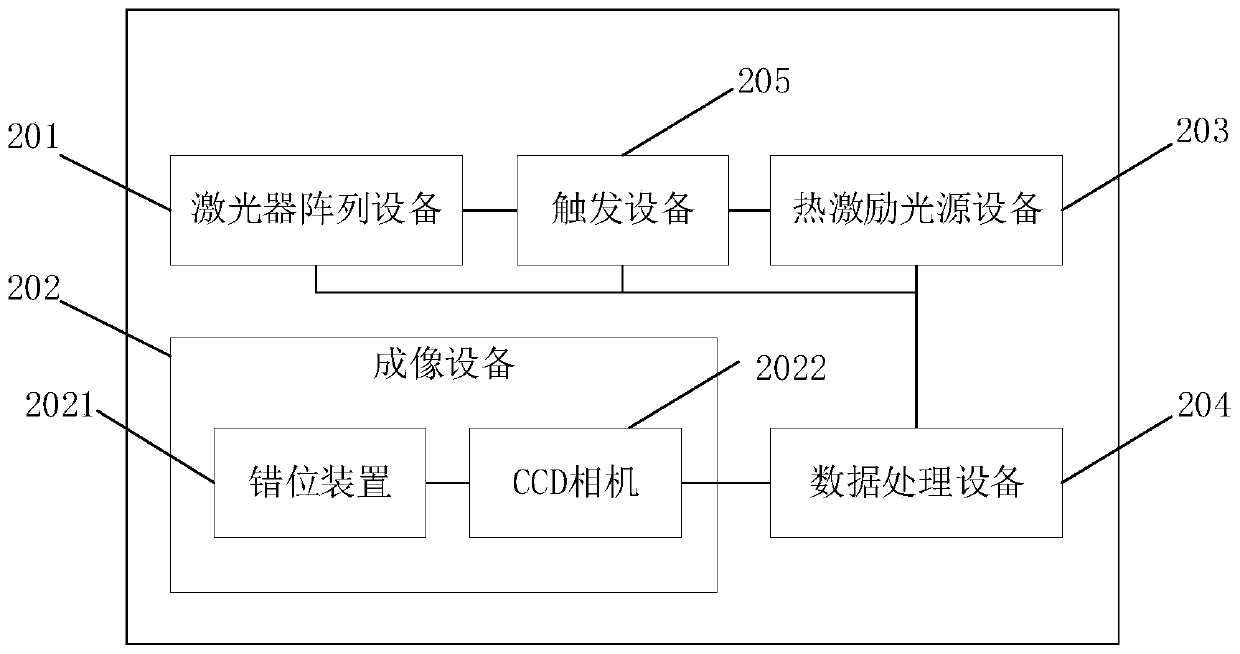

[0108] The embodiment of the present invention provides a detection system for internal bonding defects of composite insulators, which is used in the technical field of power equipment detection. Specifically, it can be used in conjunction with the first embodiment of the present invention to provide a detection method for internal bonding defects of composite insulators. Refer to image 3 As stated, the detection system for internal bonding defects of the composite insulator may include the following structure:

[0109] The laser array device 201 is used to generate a laser beam, which is projected onto the surface of the detected composite insulator through lens expansion;

[0110] Specifically, the emitted light on the surface of the insulator interferes with the reference beam directly projected by the laser array device 201 , thereby generating a speckle field on the irradiated surface of the composite insulator. The laser can control the position of the generated laser b...

Embodiment 3

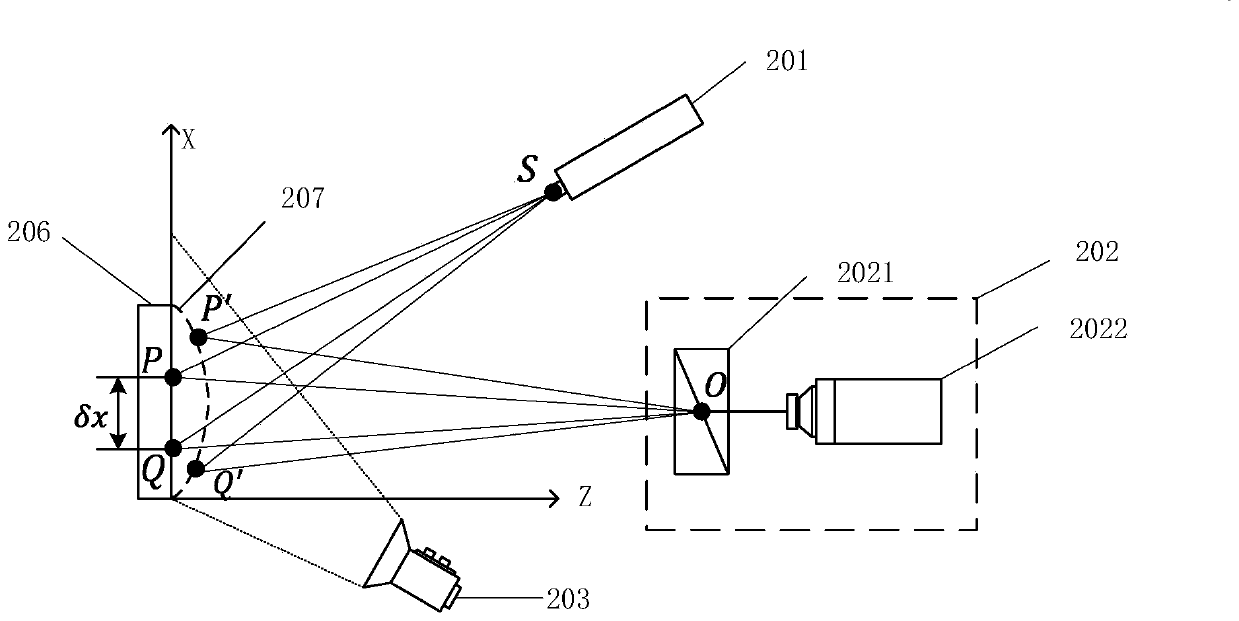

[0127] An embodiment of the present invention provides a detection system for internal bonding defects of composite insulators, which is used in the technical field of power equipment detection, and can be specifically combined with Figure 4 A schematic diagram of a detection system for internal bonding defects of composite insulators is provided to realize the detection and imaging of internal bonding defects of composite insulators.

[0128] The laser array device 201 is used to generate a laser beam, which is projected onto the surface of the detected composite insulator 206 through lens expansion;

[0129] Specifically, the emitted light on the surface of the insulator interferes with the reference beam directly projected by the laser array device 201 , thereby generating a speckle field on the irradiated surface of the composite insulator. The laser can control the position of the generated laser beam in the horizontal and vertical directions, and at the same time adopt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com