Test paper box capable of being arranged according to recent effective date and application test paper thereof

A test paper box and test paper technology, applied in non-removable covers/covers, biological tests, material inspection products, etc., can solve problems such as inability to take timely measures to deal with items, easy forgetting by managers, and no prompt effect. , to achieve a good prompt effect, easy to replace, and not easy to waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

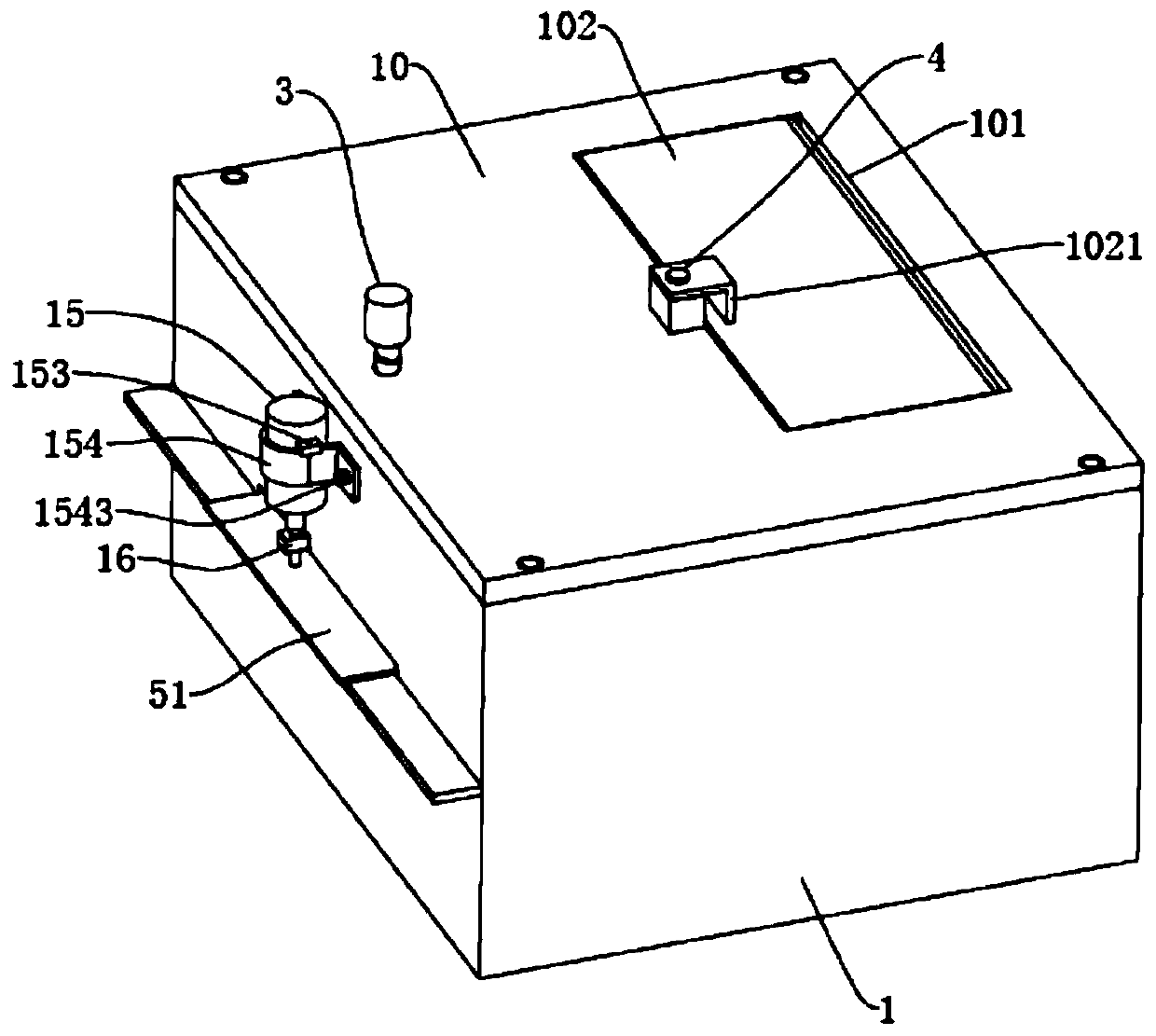

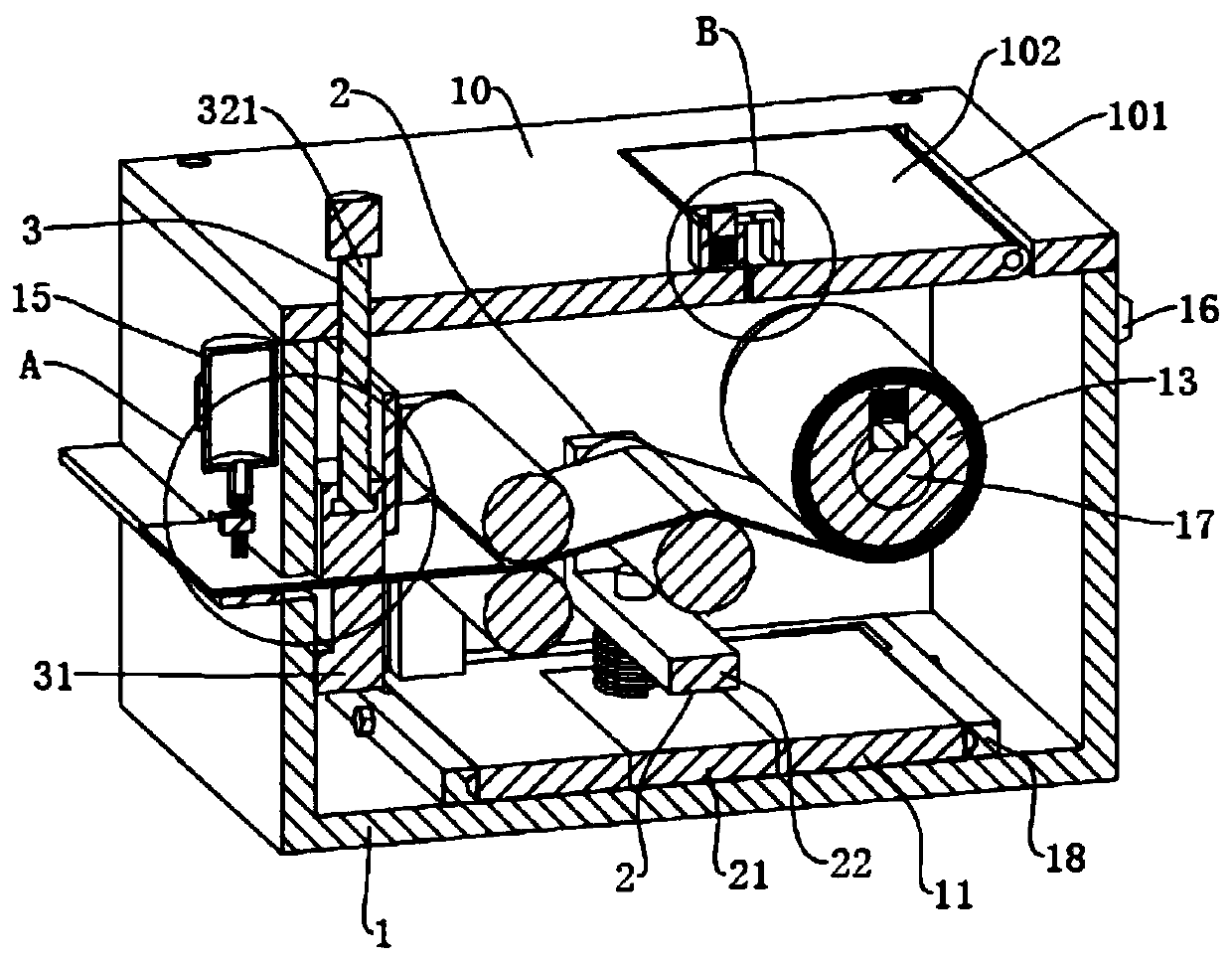

[0054] refer to figure 1 , a test paper box that can be set according to the near-expiration date, including a box body 1 and a box cover 10. In order to use the test paper box to achieve the effect of timely processing the medical articles with the near-expiration date, it is necessary to use the The test paper records the items that are about to reach their service life, and at the same time warns the operator when the items reach their service life. In order to improve the warning effect, this scheme adopts two main means of color impact and sound stimulation.

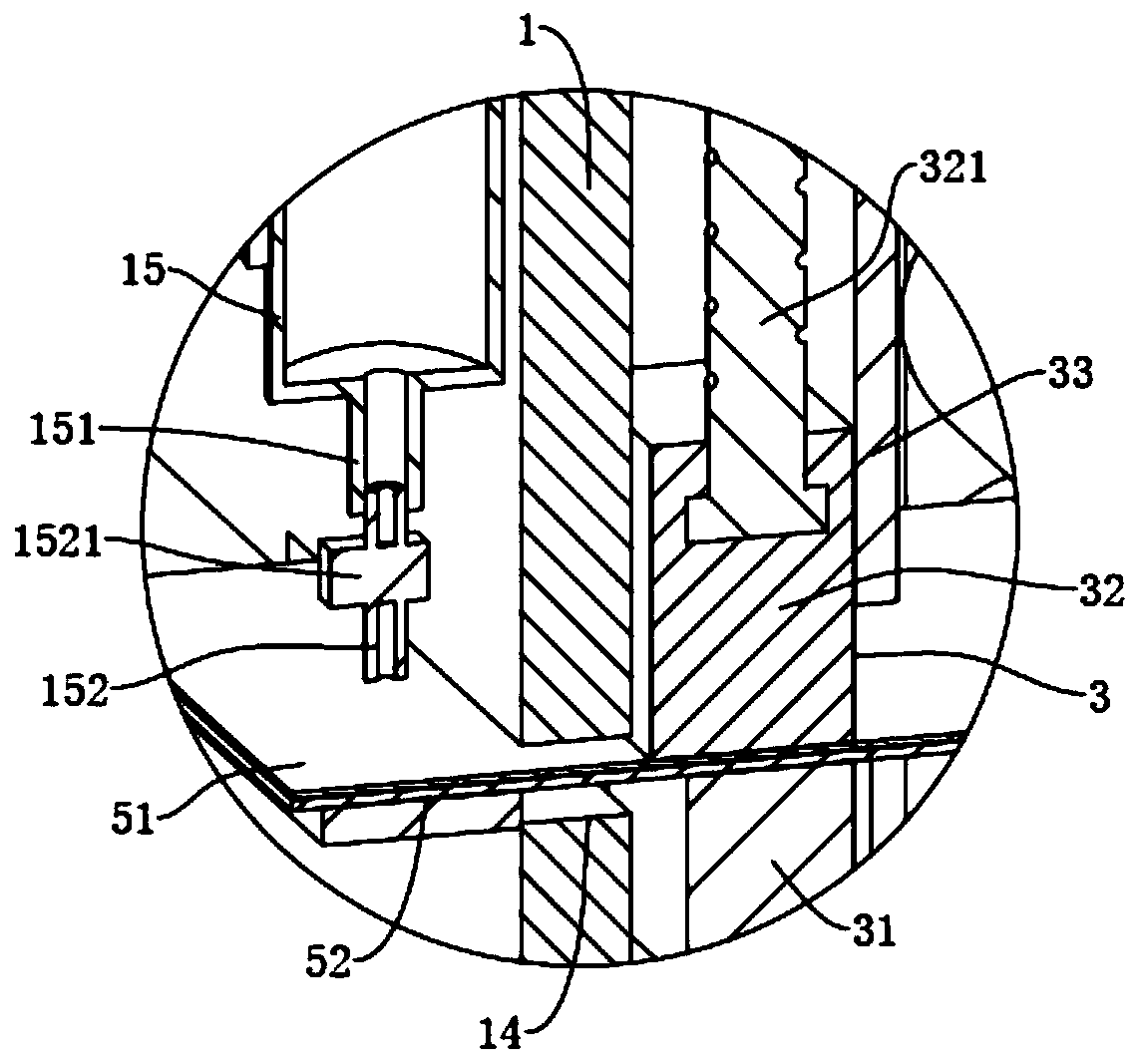

[0055] refer to figure 1 , figure 2 and image 3 , in order to facilitate the use of test paper, a base 11 is installed and fixed inside the box body 1, and a first fixed rod 12 is rotatably connected to the end of the base 11, and a coil for coil is connected to the end of the first fixed rod 12 for detachment. The winding roller 13 of the test paper is provided with a torsion spring 121 on the outside of the f...

Embodiment 2

[0065] The difference from Example 1 is that it also provides an application test paper for a test paper box that can be set according to the near-expiration date, wherein the test paper includes a polypropylene film 52 and a plurality of cut but connected test paper sheets 51, and a plurality of cut but connected test paper sheets 51 are provided. The connected test paper sheets 51 are respectively located above the polypropylene film 52 and attached and fixed thereto; since a plurality of cut but connected test paper sheets 51 are attached and fixed on the polypropylene film 52, when the test paper is torn off, It is more convenient, and the polypropylene film 52 also has a protective effect on the test paper sheet 51 at the same time.

Embodiment 3

[0067] The difference from Example 2 is that the surface of the box cover 10 is also coated with a layer of antifouling coating. After the test paper box is placed for a period of time, the box cover 10 on the box body 1 is easy to accumulate large dust. In order to facilitate the cleaning of the surface of the lid 10, the surface of the lid 10 is coated with an antifouling coating, wherein the preparation method of the antifouling coating is as follows:

[0068] Take the following raw materials of each component by weight for later use: 45 parts of methyl methacrylate, 30 parts of polypropylene, 26 parts of n-butyl titanate, 24 parts of polytetrafluoroethylene, and 23 parts of polyethylene terephthalate , 20 parts of fluoroethylene carbonate, 20 parts of alkylphenol polyoxyethylene ether, 15 parts of sodium acrylate, and 8 parts of dimethyl sulfoxide;

[0069] S1. Prepare antifouling coating pre-preparation solution; mix methyl methacrylate, polypropylene, n-butyl titanate, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com