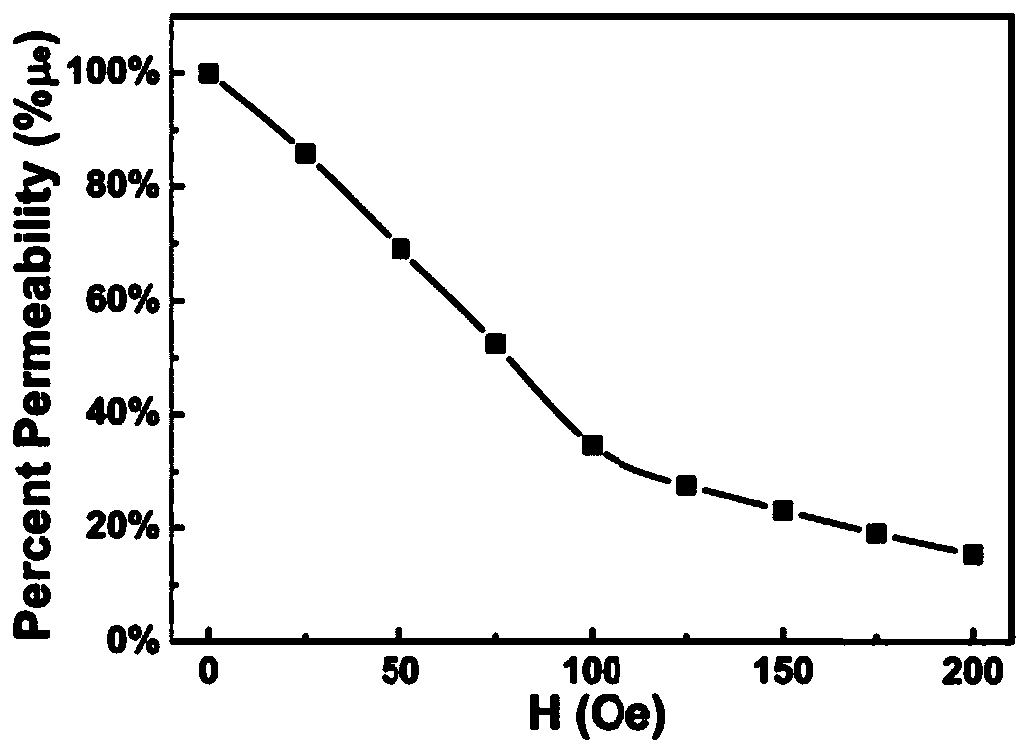

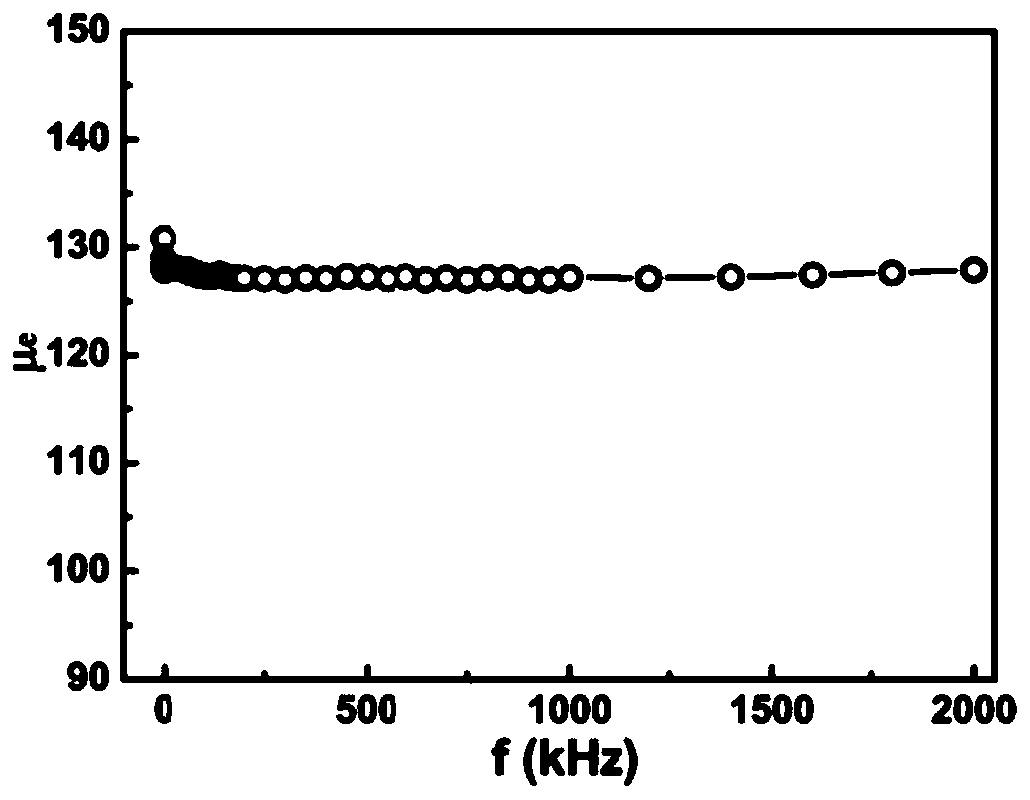

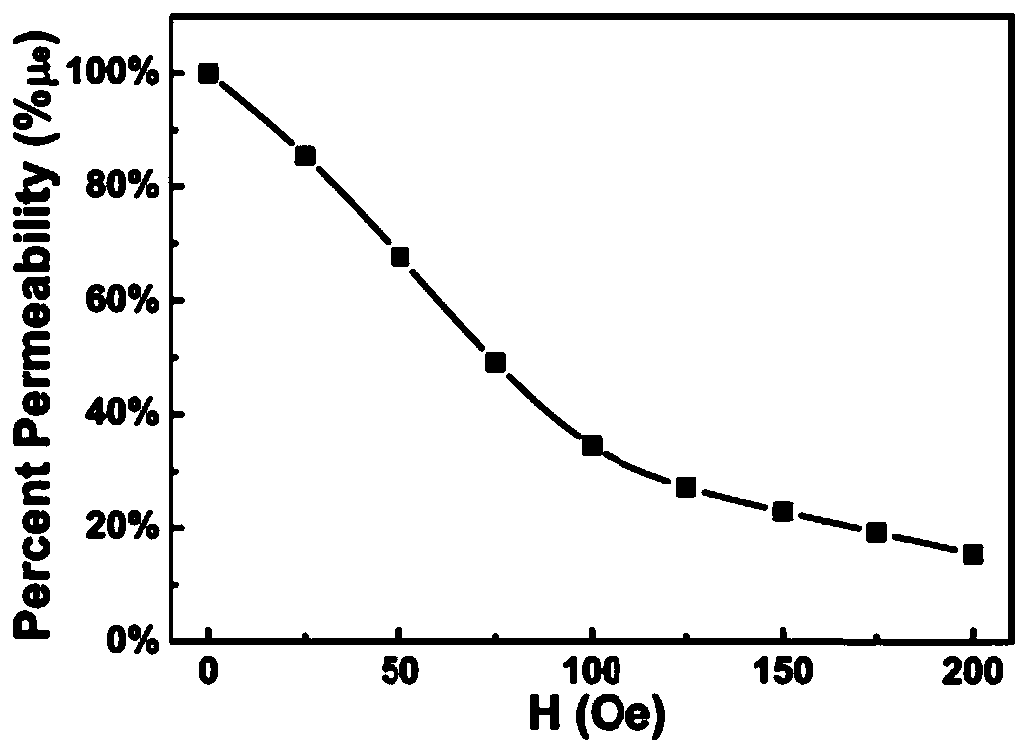

Iron-silicon-aluminum-nickel soft magnetic powder core with effective magnetic permeability of 125 for boost inductor and preparation method thereof

An iron-silicon-aluminum-nickel and magnetic permeability technology, applied in the field of iron-silicon-aluminum-nickel soft magnetic powder core and its preparation, can solve the problems of low DC superposition performance and high loss level of iron-silicon powder core, achieve easy operation and control, improve performance, the effect of avoiding environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Select the commercially available alloy with the particle size of -200 mesh as Si 4.0%, Al 3.5%, Ni 2.0% by mass percentage respectively, and the remainder is Fe-susilicate-nickel magnetic powder 1000.0g; then, add 0.3g of epoxy resin, 1.0g of SiO 2Powder, 10.0g of acetone and 90.0g of water were stirred at room temperature for 20 minutes to form a uniform mixed slurry; then, the mixed slurry was heated to 100°C and kept stirring for 35 minutes. The Sensitive Aluminum Nickel insulating powder is sieved with a 100-mesh sieve; 3.0 g of polyamide resin binder and 4.0 g of talcum powder release agent are added to the sieved powder, and mixed evenly to obtain The magnetic powder; the uniformly mixed powder is pressed into a powder core blank with a pressing pressure of about 2300MPa, wherein the powder core blank is an annular powder core with an outer diameter of 33.02mm x an inner diameter of 19.94mm x a height of 10.67mm; nitrogen is used as a protective Gas, heat the pr...

Embodiment 2

[0050] The raw powder particle size is selected as -200 purpose commercially available alloy composition mass percent is Si 4.0%, Al 3.5%, Ni 2.0% respectively, the remainder is the sendust magnetic powder 1000.0g of Fe; Then, add 0.8g epoxy resin, 0.5g of SiO 2 Powder, 10.0g of acetone and 90.0g of water were stirred at room temperature for 20 minutes to form a uniform mixed slurry; then, the mixed slurry was heated to 140°C and kept stirring for 15 minutes. The Sensilicon Alnickel insulating powder was sieved with a 100-mesh sieve; 3.0g of phenolic resin binder and 4.0g of mica powder release agent were added to the sieved powder, and mixed evenly, using a pressing pressure of about Press the uniformly mixed powder into a powder core blank at 2500MPa, wherein the powder core blank is an annular powder core with an outer diameter of 33.02mm x an inner diameter of 19.94mm x a height of 10.67mm; using nitrogen as a protective gas, the pressed powder The core blank is kept at 8...

Embodiment 3

[0058] Select 1000.0g of sendust magnetic powder whose grain size is -200 mesh and the mass percentages of commercially available alloy components are Si 4%, Al 4.5%, Ni 1.5%, and the rest is Fe; then, add 0.5g of epoxy resin , 0.7g of SiO 2 Powder, 10.0g of acetone and 90.0g of water were stirred at room temperature for 20 minutes to form a uniform mixed slurry; then, the mixed slurry was heated to 120°C and kept stirring for 25 minutes. The SensiAlNi insulating powder is sieved with a 100-mesh sieve; 3.0 g of silicone resin binder and 4.0 g of zinc stearate release agent are added to the sieved powder, and mixed uniformly, The magnetic powder to be formed is obtained; the uniformly mixed powder is pressed into a powder core blank with a pressing pressure of about 2800MPa, wherein the powder core blank is an annular powder core with an outer diameter of 33.02mm×an inner diameter of 19.94mm×a height of 10.67mm; As a protective gas, heat the pressed powder core blank at 900°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Inductance | aaaaa | aaaaa |

| Inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com