Method for selectively preparing gold-tin eutectic solder on surface of ceramic thin film circuit of 5G optical module

A technology of ceramic film and eutectic solder, which is applied in the manufacture of printed circuits, assembly of printed circuits with electric components, printed circuits, etc., can solve the problems of alignment deviation, easy decomposition, and dislocation movement, etc., to improve accuracy and Yield rate, meet small chip welding requirements, good wettability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0031] The problem to be solved by the present invention is to provide a method for selectively preparing gold-tin eutectic solder on the surface of ceramic thin film circuits for 5G optical modules with good stability and wide application range.

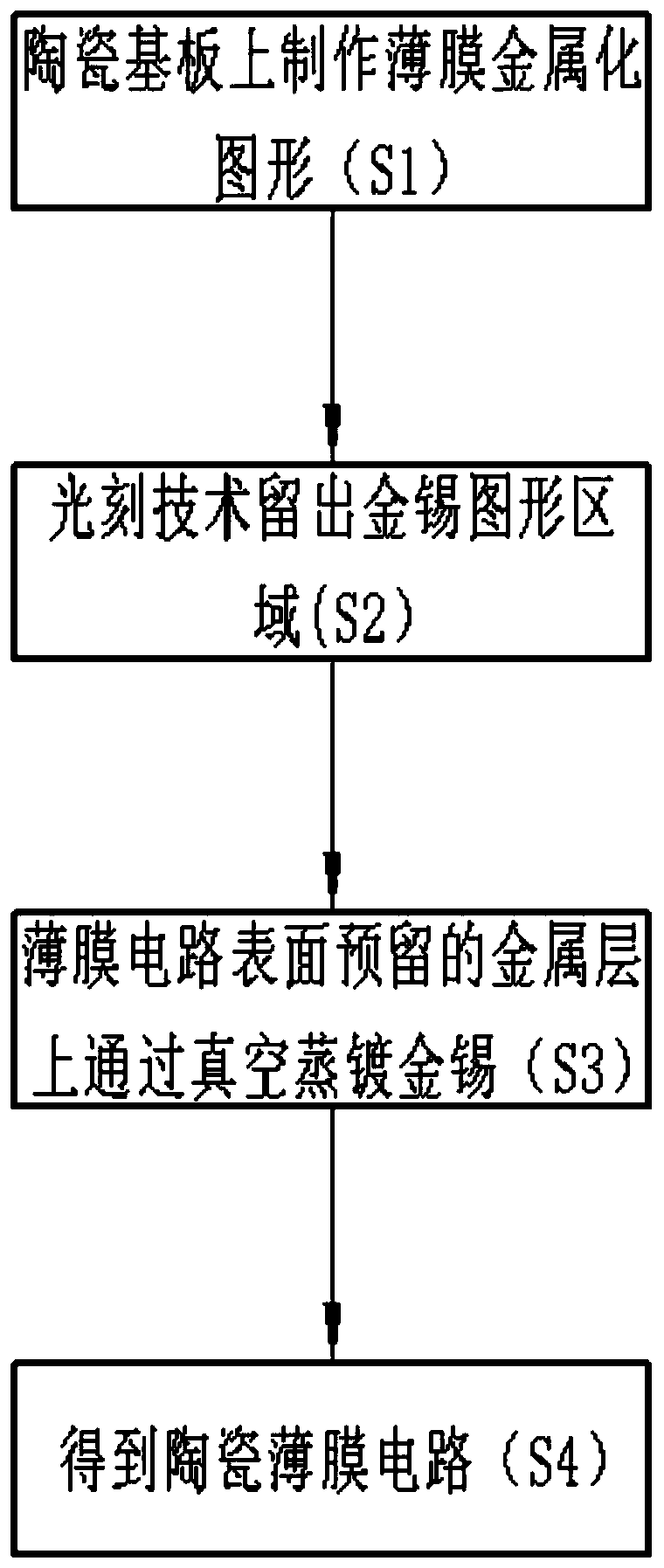

[0032] Such as figure 1 As shown, in order to achieve the technical purpose, the technical solution of the present invention is: the present invention relates to a method for selectively preparing gold-tin eutectic solder on the surface of a ceramic thin film circuit for a 5G optical module, comprising the following steps:

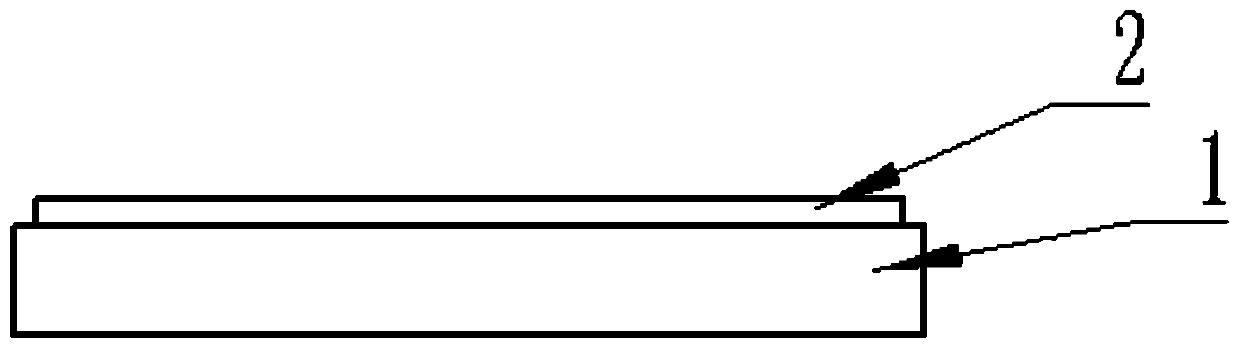

[0033] S1: making a thin film metallization pattern on a ceramic substrate;

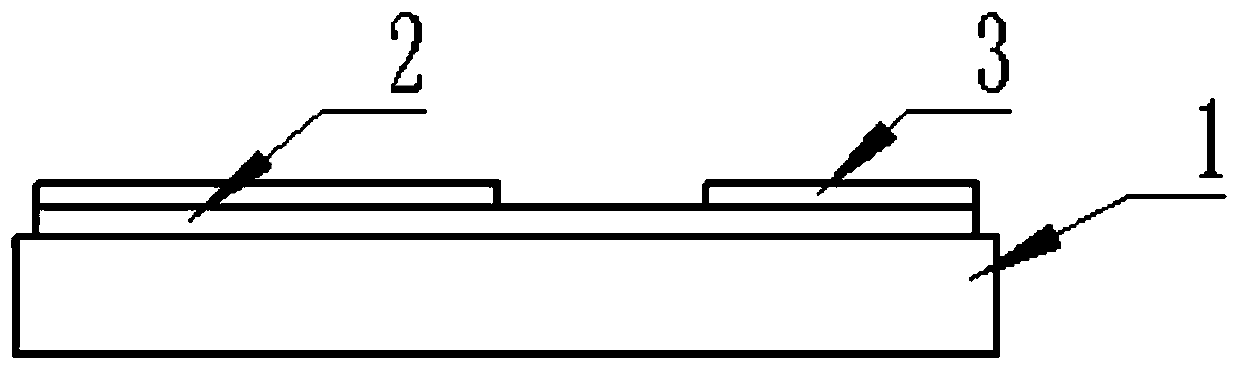

[0034] S2: Leave a gold-tin pattern area by photolithography in the designated area of the film metallization surface;

[0035] S3: Vacuum evaporation of gold and tin on the metal layer reserved on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com