Molybdate-based red fluorescent powder, preparation method and application thereof

A citric acid and rare earth luminescent technology, which is applied in chemical instruments and methods, luminescent materials, etc., can solve the problem of rare earth luminescent materials, and achieve the effects of low synthesis cost, high physical and chemical stability, and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the rare-earth luminescent material with luminescent properties: the following steps are carried out:

[0046] a. Raw material preparation: according to LiLa(MoO 4 ) 2 :xSm 3+ ,yAg + The stoichiometric ratio of each element in the formula is taken as Li 2 CO 3 (99.0%), La 2 o 3 (99.9%), AgNO 3 (99.0%), (NH 4 ) 6 Mo 7 o 24 4H 2 O (99.0%), C 6 h 8 o 7 (99.8%), Sm 2 o 3 (99.99%); wherein, 1%≤x≤9%, 0.5%≤y≤6%. ;

[0047] b. Take the good one from step a (NH 4 ) 6 Mo 7 o 24 4H 2 O is added with distilled water to prepare (NH 4 ) 6 Mo 7 o 24 solution, for use; the Sm taken in step a 2 o 3 , La 2 o 3 , Li 2 CO 3 Add dilute nitric acid to prepare Sm(NO 3 ) 3 , La(NO 3 ) 3 、LiNO 3 solution, stand-by; the AgNO taken in step a 3 Adding distilled water to prepare AgNO 3 solution, ready to use;

[0048] c. The AgNO prepared in step b 3 The solution was added to the prepared Sm(NO 3 ) 3 , La(NO 3 ) 3 、LiNO 3 solu...

Embodiment 1

[0073] Weigh 1.4124g (NH 4 ) 6 Mo 7 o 24 4H 2 O was prepared by adding 10 mL of distilled water (NH 4 ) 6 Mo 7 o 24 Solution, heated and stirred to 70°C, set aside; weighed Li 2 CO 3 , La 2 o 3 , Sm 2 o 3 Add 1.5mL of 40% dilute nitric acid to form a nitrate solution, heat and stir to 77°C, and set aside; weigh 2.304g of anhydrous citric acid and add it to the stirred nitrate solution, continue heating and stirring until a clear solution; prepare ( NH 4 ) 6 Mo 7 o 24 Put the solution into the prepared clear solution, heat and stir at 70°C for 1h to obtain a light yellow transparent gel-like precursor; roast the precursor in a muffle furnace at 700°C for 1h to obtain LiLa 1-x (MoO 4 ) 2 :xSm 3+ Phosphor.

[0074] SM 2 o 3 and La 2 o 3 The corresponding amount changes are shown in Table 1.

[0075] Table 1

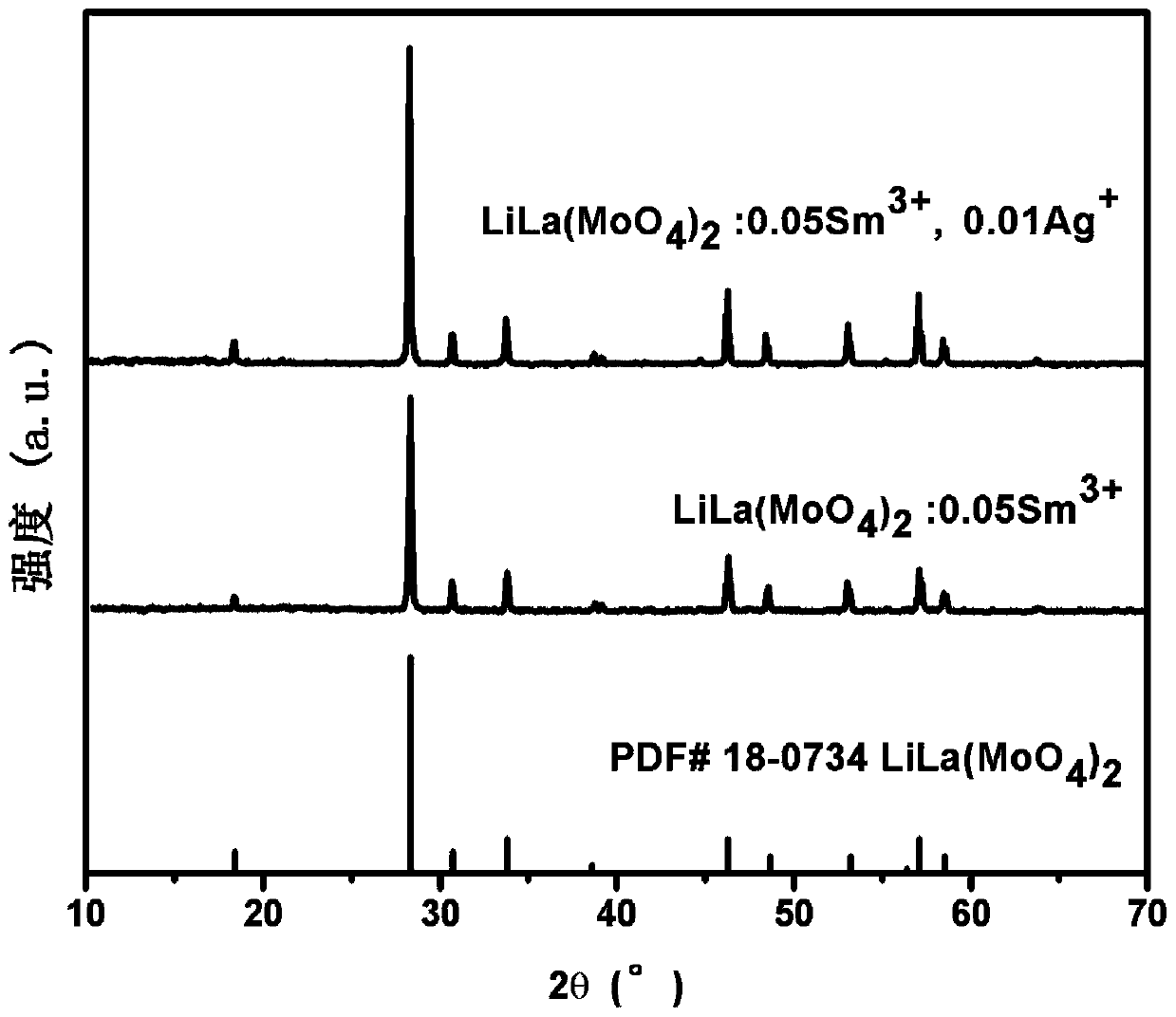

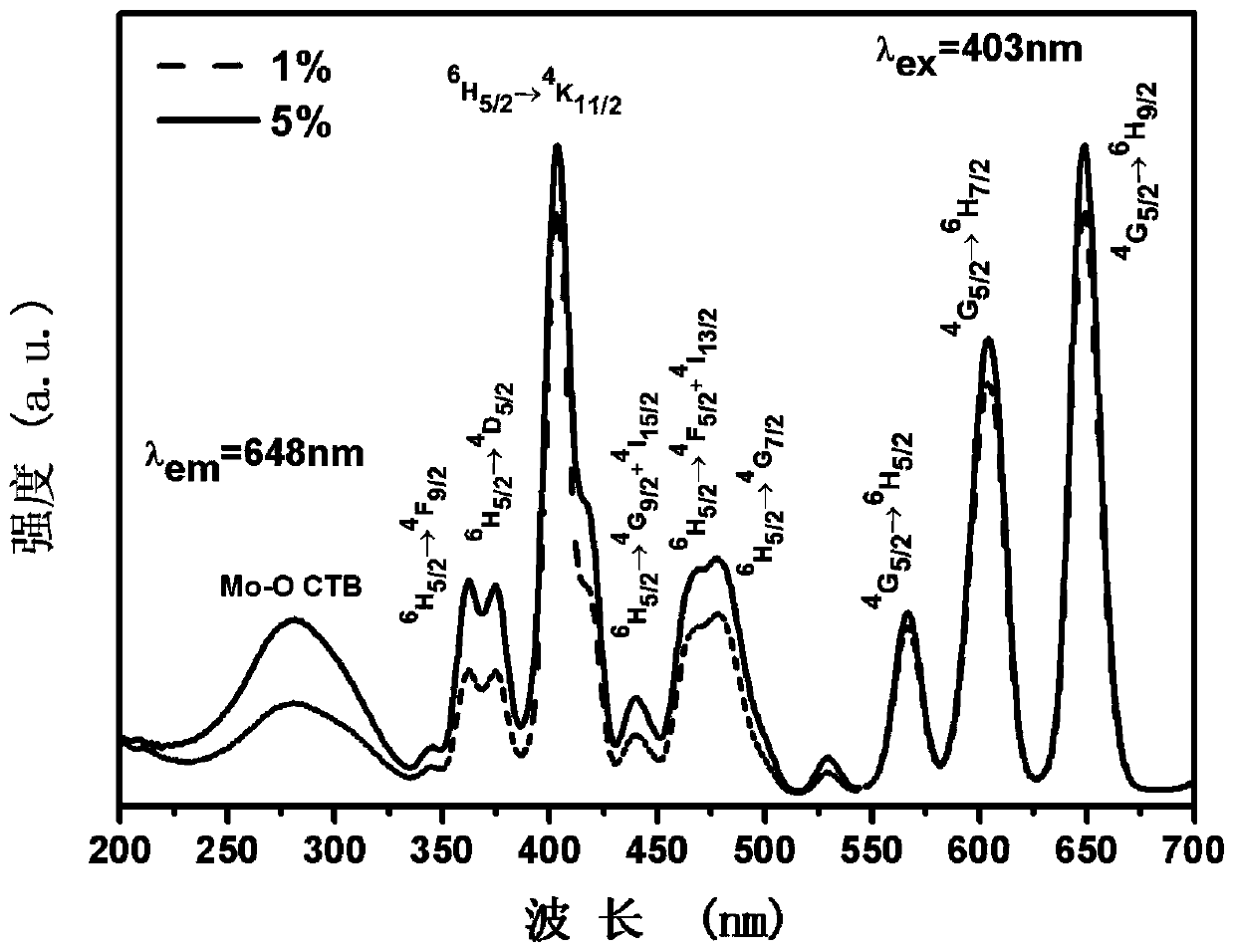

[0076] LiLa(MoO 4 ) 2 :xSm 3+

Embodiment 2

[0078] On the basis of Example 1, change Li 2 CO 3 , AgNO 3 The amount of LiLa(MoO 4 ) 2 :0.05Sm 3+ ,yAg + Phosphor. The chemical formula of the product obtained is: LiLa(MoO 4 ) 2 :0.05Sm 3+ ,yAg + (y=0.5%-6%). AgNO 3 and Li 2 CO 3 The corresponding quantity changes are shown in Table 2.

[0079] Table 2

[0080]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com