A method for preparing multilayer polymer microneedles

A technology of polymers and polymer sheets, which is applied in the direction of microneedles, medical devices, needles, etc., can solve the problems of high preparation cost, complicated preparation process, and long preparation cycle, and achieve simple process operation, high micromachining precision, Effect of Controlling Drug Dissolution Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a method for preparing a four-layer composite microneedle loaded with lidocaine and acetylspiramycin. The preparation method includes the following steps:

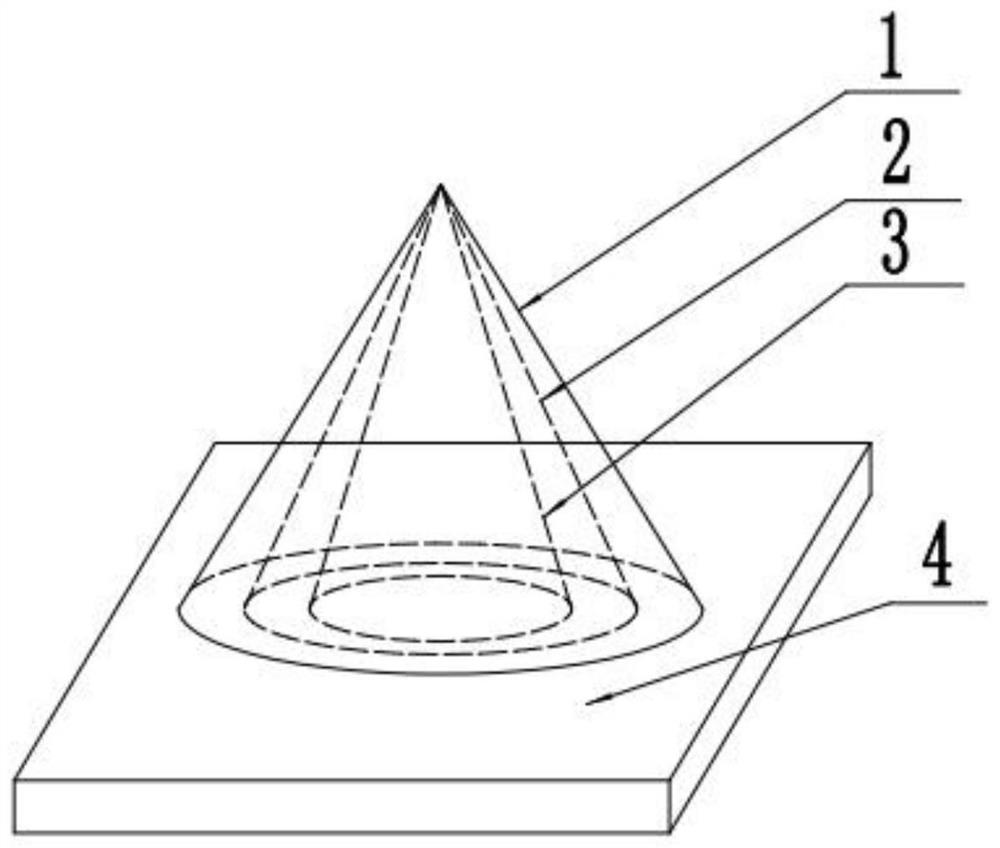

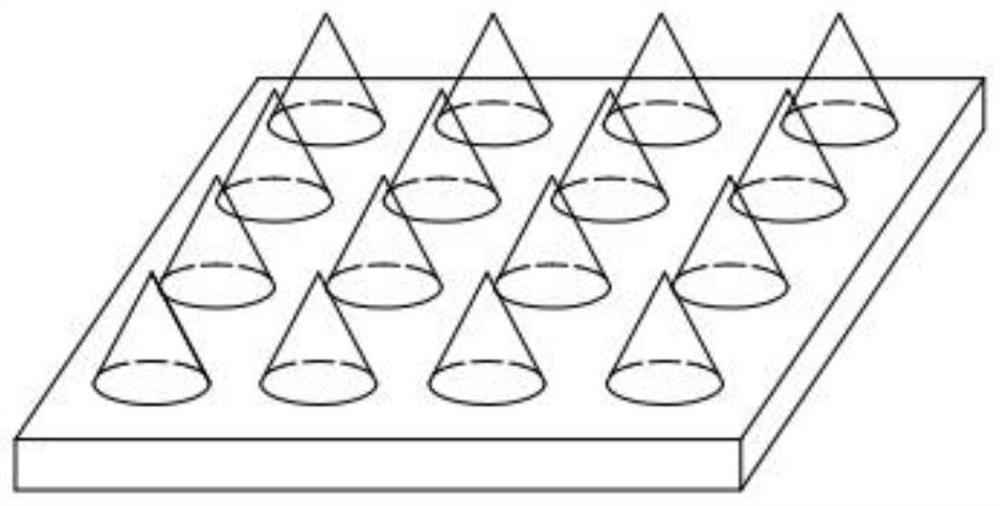

[0028] (1) Preparation of microneedle base layer: The mold used in the experiment is made of stainless steel, and 7×7 microneedle concave-shaped frustum-shaped arrays are distributed on the mold. (The major diameter of the truncated cone) is 0.25mm, the top diameter (the minor diameter of the truncated cone) is 0.05mm, and the depth is 0.55mm. Polylactic acid (PLA) is selected as the polymer material, and the glass transition temperature of PLA is 56°C. Place the microstructure mold and PLA sheet between the upper and lower mold bases of the micro-thermal embossing equipment, and then heat the mold and PLA sheet to a hot embossing temperature of 112°C; load the mold to press it into the softened PLA sheet In the process, adjust the pressure to 4.10MPa, and keep the pressure for a certain ti...

Embodiment 2

[0032] This embodiment provides a method for preparing a four-layer composite microneedle loaded with ibuprofen and gentamicin. The preparation method includes the following steps:

[0033] (1) Preparation of microneedle base layer: The mold used in the experiment is made of stainless steel, and 7×7 microneedle concave-shaped frustum-shaped arrays are distributed on the mold. (The major diameter of the truncated cone) is 0.25mm, the top diameter (the minor diameter of the truncated cone) is 0.05mm, and the depth is 0.55mm. The polymer material is polymethyl methacrylate (PMMA), and the glass transition temperature of PMMA is 105°C. Place the microstructure mold and PMMA sheet between the upper and lower mold bases of the micro-thermal embossing equipment, then heat the mold and PMMA sheet to a hot embossing temperature of 116°C; load the mold to press it into the softened PMMA sheet In the process, the pressure is adjusted to 7.08MPa, and the pressure is maintained for a cert...

Embodiment 3

[0037] This embodiment provides a method for preparing a four-layer composite microneedle loaded with albuterol and norfloxacin. The preparation method includes the following steps:

[0038] (1) Preparation of microneedle base layer: The mold used in the experiment is made of stainless steel, and 7×7 microneedle concave-shaped frustum-shaped arrays are distributed on the mold. (The major diameter of the truncated cone) is 0.25mm, the top diameter (the minor diameter of the truncated cone) is 0.05mm, and the depth is 0.55mm. Polycarbonate (PC) is selected as the polymer material, and the glass transition temperature of PC is 150°C. Place the microstructure mold and PC sheet between the upper and lower mold bases of the micro-thermal embossing equipment, and then heat the mold and PC sheet to a hot embossing temperature of 120°C; load the mold to press it into the softened PC sheet In the process, adjust the pressure to 10.00MPa, and keep the pressure for a certain period of ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com