Carrier dyeing process of polybutylene succinate fibers

A polybutylene succinate, carrier dyeing technology, applied in the direction of dyeing, textile and papermaking, etc., can solve the problems of low dye uptake in ordinary dyeing, achieve high color fastness, and solve the problem of low dye uptake. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

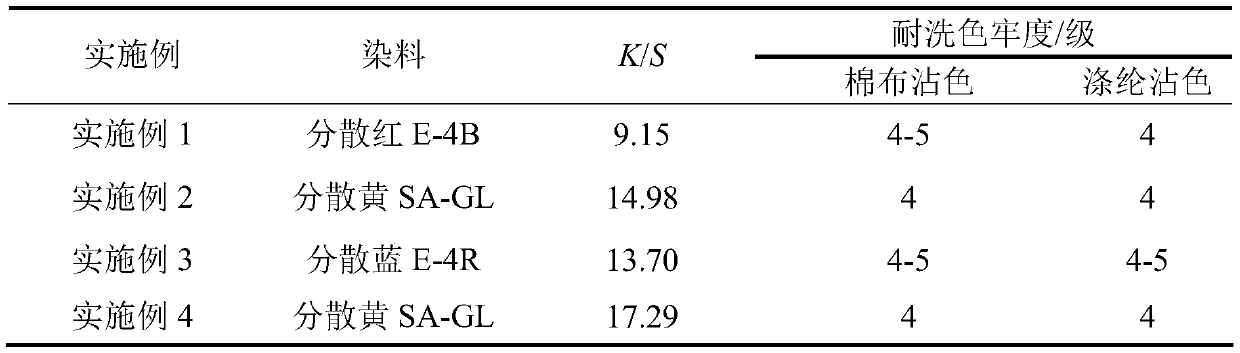

Embodiment 1

[0025] (1) The impurity removal process is: polybutylene succinate fiber is added to the treatment solution containing 2g / L detergent POEA and 2g / L sodium carbonate, treated at 60°C for 30min, washed with water and dried spare.

[0026] (2) carrier preparation process is: dodecyl dimethyl benzyl ammonium chloride consumption 1%, dimethyl succinate consumption 10%, water consumption replenishes to 100% (percentages are volume ratio), The emulsification temperature is room temperature, the emulsification time is 10 minutes, and the rotation speed of the emulsification machine is 8000 rpm.

[0027] (3) The dyeing process is: low-temperature disperse dye 2% (o.w.f), pH=5, carrier dosage 10g / L, liquor ratio 1:30. The reduction cleaning process is as follows: 2g / L sodium hydroxide, 2g / L sodium hydroxide, bath ratio 1:30, reduction cleaning at 60°C for 20 minutes, washing with water and drying.

Embodiment 2

[0029] (1) The impurity removal process is: polybutylene succinate fibers are added to the treatment solution containing 2g / L detergent 6501 and 2g / L sodium carbonate, treated at 60°C for 30min, washed with water and dried spare.

[0030] (2) The carrier preparation process is: octadecyltrimethylammonium chloride consumption 2%, diethyl succinate consumption 15%, water consumption supplemented to 100% (percentages are volume ratio), emulsification temperature Room temperature, emulsification time 20min, emulsifier speed 10000rpm.

[0031] (3) The dyeing process is: disperse dye 3% (o.w.f), pH=6, carrier dosage 15g / L, liquor ratio 1:40. The reduction cleaning process is as follows: 2g / L sodium hydroxide, 2g / L sodium hydroxide, bath ratio 1:30, reduction cleaning at 70°C for 10 minutes, washing with water and drying.

Embodiment 3

[0033] (1) The impurity removal process is: polybutylene succinate fiber is added to the treatment solution containing 2g / L detergent POEA and 2g / L sodium carbonate, treated at 60°C for 30min, washed with water and dried spare.

[0034] (2) The carrier preparation process is: sodium lauryl sulfate and Tween 80 consumption 2%, ethyl acetate consumption 15%, water consumption supplemented to 100% (percentages are volume ratio), emulsification temperature is room temperature , emulsification time 20min, emulsifier speed 10000rpm.

[0035] (3) The dyeing process is: disperse dye 2% (o.w.f), pH=5, carrier dosage 15g / L, liquor ratio 1:30. The reduction cleaning process is as follows: 2g / L sodium hydroxide, 2g / L sodium hydroxide, bath ratio 1:20, reduction cleaning at 60°C for 15 minutes, washing with water and drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com