Preparation method of high-melting-point AKD type surface sizing agent

A surface sizing agent, high melting point technology, applied in the direction of adding water repellent, can solve the problems of no obvious improvement in the surface strength of paper, slow AKD curing speed, poor sizing effect, etc., to improve water resistance and film formation. performance, improvement of paper surface strength, effect of improving surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

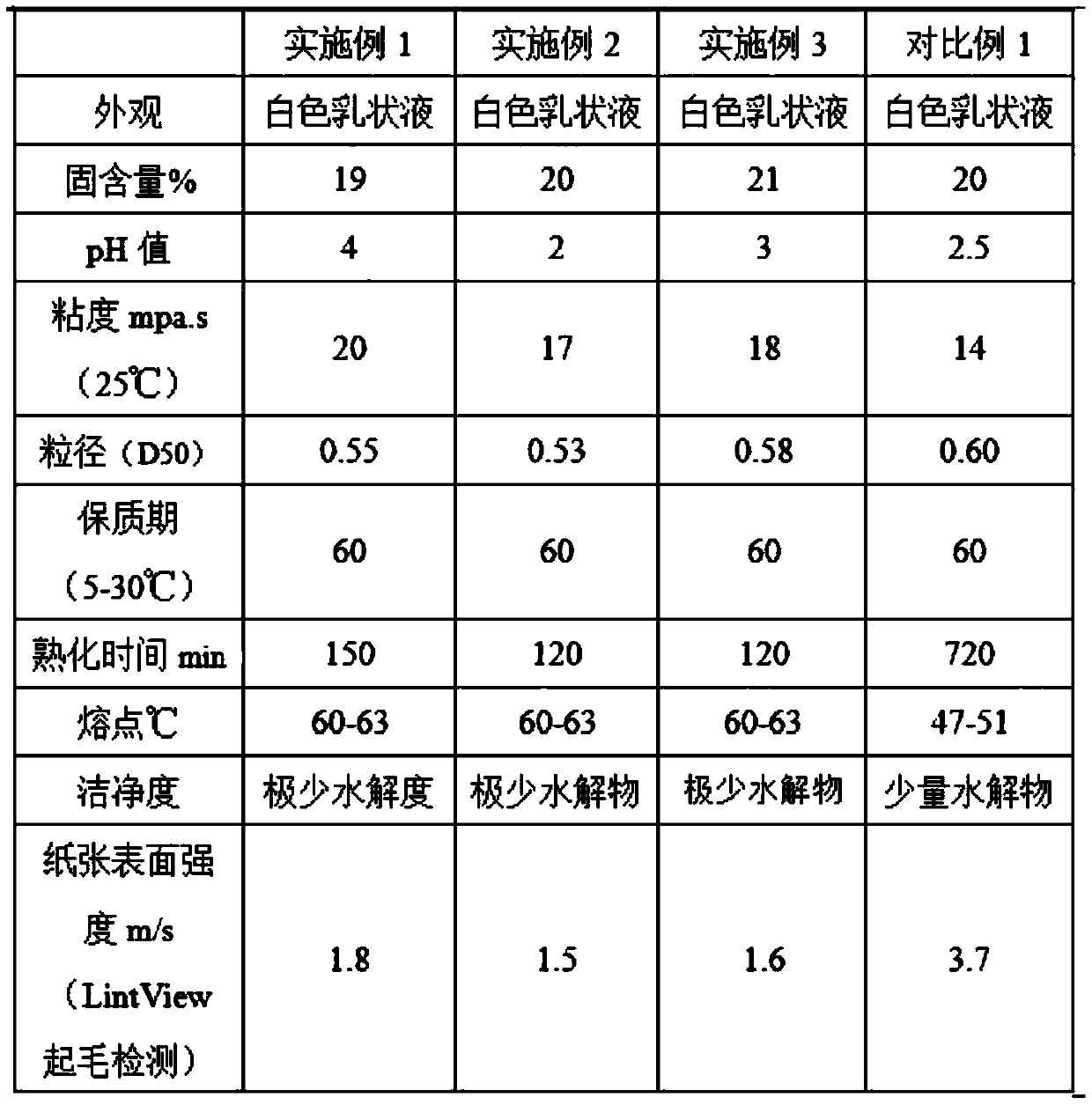

Examples

Embodiment 1

[0024] A preparation method of high melting point AKD type surface sizing agent, comprising the following steps:

[0025] Step 1. Preparation of starch emulsifier: in terms of mass percentage, add 30% deionized water to the reactor, add 20% tapioca oxidized starch under stirring, continue stirring for 30 minutes, then heat up to 40°C, then add 5% liquid caustic soda , keep warm for 20min, continue to heat up to 65°C, add 7% cationic etherification agent, keep warm for 20min, continue to heat up to 73°C, keep warm for 3.5h, stop stirring for 3h, add 27% water, 10% glacial acetic acid to adjust the pH value to 3.5 , after cooling down to 60°C, add 1% dispersant N, stir for 20 minutes and start to heat up to 92°C, keep warm for 50 minutes, and then continue to cool down to 65°C to obtain a starch emulsifier;

[0026] Step 2. Prepare the finished product: Add 26% deionized water and 0.06% dispersant N to the shearing tank in terms of mass percentage, add the 10% starch emulsifier ...

Embodiment 2

[0028] A preparation method of high melting point AKD type surface sizing agent, comprising the following steps:

[0029] Step 1. Preparation of starch emulsifier: in terms of mass percentage, add 35% deionized water to the reaction kettle, add 19% tapioca oxidized starch under stirring, continue stirring for 20 minutes, then heat up to 45°C, then add 6% liquid caustic soda , keep warm for 30 minutes, continue to heat up to 60°C, add 9% cationic etherification agent, keep warm for 30min, continue to heat up to 76°C, keep warm for 3h, stop stirring for 4h, add 20% water, 9% glacial acetic acid to adjust the pH value to 5.5, After cooling down to 65°C, add 2% dispersant N, stir for 30 minutes and start to heat up to 95°C, keep warm for 60 minutes, and then continue to cool down to 60°C to obtain a starch emulsifier;

[0030] Step 2. Prepare the finished product: add 30% deionized water and 0.03% dispersant N to the shearing tank in terms of mass percentage, add the 8.24% starch ...

Embodiment 3

[0032] A preparation method of high melting point AKD type surface sizing agent, comprising the following steps:

[0033] Step 1. Preparation of starch emulsifier: In terms of mass percentage, add 32% deionized water to the reaction kettle, add 18% tapioca oxidized starch under stirring, continue stirring for 25 minutes, then heat up to 42°C, and then add 5.5% liquid caustic soda , keep warm for 25min, continue to heat up to 62°C, add 8% cationic etherification agent, keep warm for 26min, continue to heat up to 75°C, keep warm for 3.4h, stop stirring for 3.5h, then add 30% water and 5% glacial acetic acid to adjust the pH value to 4. After cooling down to 62°C, add 1.5% dispersant N, stir for 25 minutes and start to heat up to 94°C, keep warm for 55 minutes, and then continue to cool down to 62°C to obtain a starch emulsifier;

[0034]Step 2. Prepare the finished product: add 25% deionized water and 0.05% dispersant N to the shearing tank in terms of mass percentage, and add 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com