High-energy and high-safety lithium ion battery

A lithium-ion battery, safety performance technology, applied in the direction of battery electrodes, secondary batteries, secondary battery repair/maintenance, etc., can solve the problems of limiting battery energy density, safety performance degradation, etc., to improve battery rate performance and energy Density, the effect of ensuring the safety performance of anti-acupuncture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A high-energy and high-safety lithium-ion battery includes a battery core formed by stacking or winding a negative electrode sheet, a separator, and a positive electrode sheet.

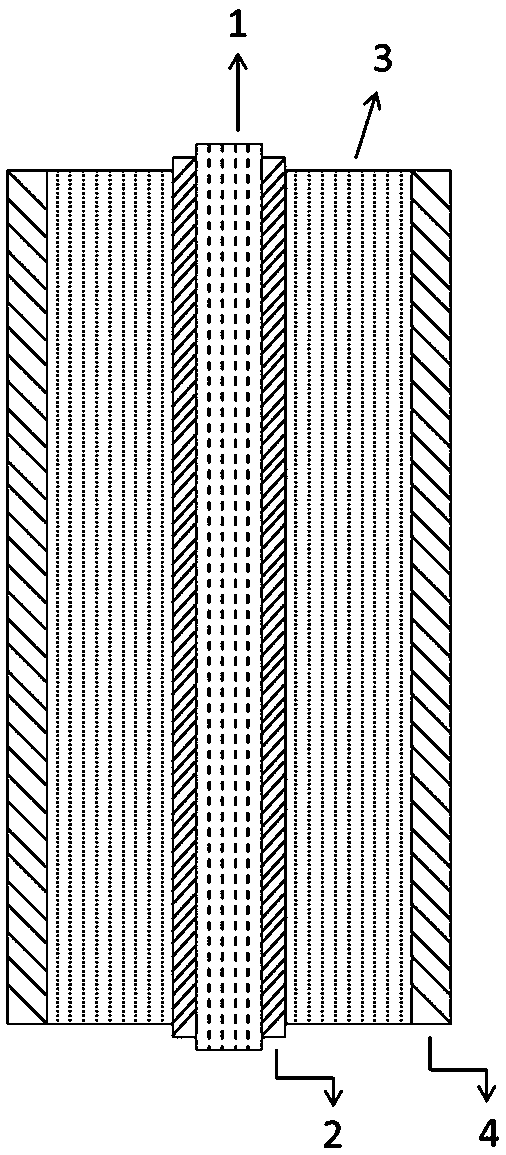

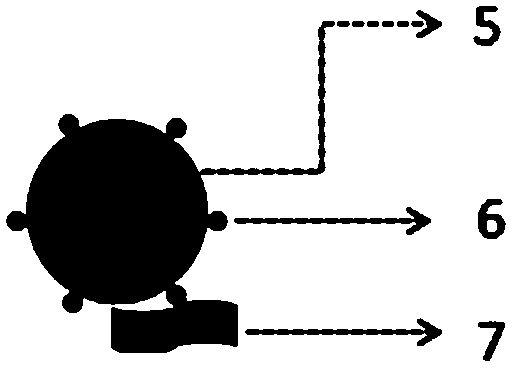

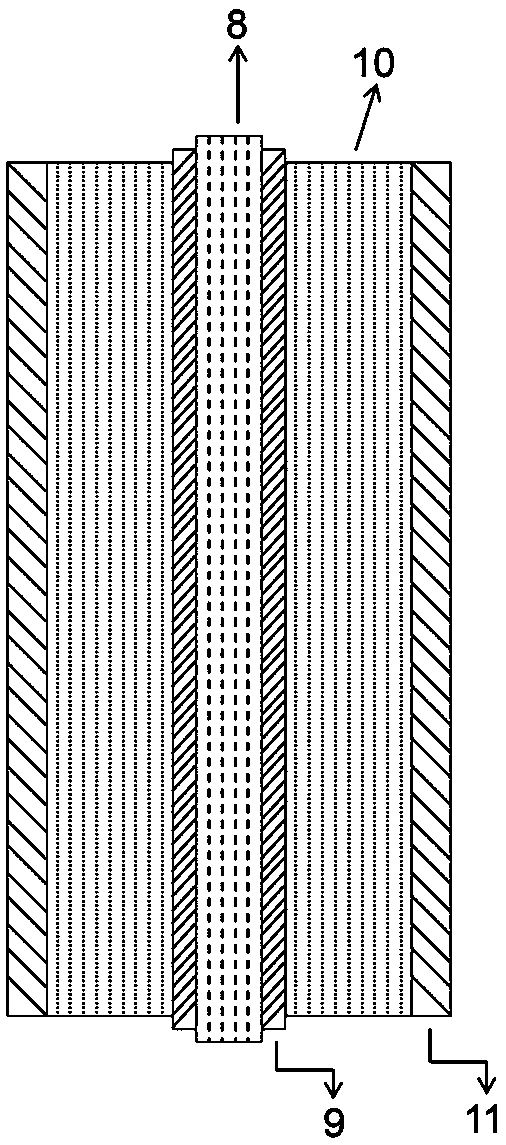

[0036] See attached figure 1 The positive electrode sheet is composed of a positive electrode current collector foil 1 in the center, a positive electrode current collector coating 2 , a positive electrode slurry coating 3 , and a positive electrode surface coating 4 on both sides of the positive electrode current collector foil 1 . Among them, the positive electrode current collector foil 1 is made of aluminum foil, the positive electrode current collector coating 2 is composed of PTC materials, aluminum powder and carbon nanotubes, and the positive electrode slurry coating 3 is composed of positive electrode active materials, positive electrode conductive agents, positive electrode binders and positive electrode additives. constitute. See attached figure 2 , the positive electrode additive...

Embodiment 2

[0055] The VDA standard (DIN 91252-2016) square 2614891 size battery cell is selected, the battery capacity is 54Ah, the energy density is 230Wh / kg, and the positive electrode material is 811 ternary with the highest nickel content in commercialization. According to the "Safety Requirements and Test Methods for Traction Batteries for Electric Vehicles" (GB / T 31485-2015), the acupuncture test was carried out, and the test results are shown in Table 4, Table 5, Table 6, and Table 7.

[0056] It can be seen from Table 4 that due to the high-nickel positive electrode system, when the thickness of the surface coating of the current collector and the content of additives in the positive and negative electrodes are too low, even if the thickness of the surface coating of the positive and negative electrodes is increased by 2 μm on one side, the safety cannot be fully guaranteed. performance. It can be seen from Table 5 that when the thickness of one side of the surface coating of the...

Embodiment 3

[0068] After the coating and rolling of the electrode sheet in the lithium-ion battery, there will be a cutting process, which is mainly to cut off the excess exposed metal current collector to reduce its own weight and make room. Laser slicing is likely to cause high internal short circuit rate, self-discharge and inconsistency due to the phenomenon of molten beads, so the current mainstream of slitting is hardware die cutting and knife die slicing. The principle of metal die cutting and knife die slicing causes burrs after the current collector metal is cut. The existence of burrs affects the short circuit rate of the process, and ultimately affects the self-discharge of the battery, showing the inconsistency of the group.

[0069]The length and width of the surface coating of the current collector are both smaller than the length and width of the inner layer of the current collector, and larger than the length and width of the coating of the outer slurry (active material, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com