Current collector and preparation method and application thereof

A technology of current collector and liquid crystal polymer, applied in the direction of electrode carrier/current collector, etc., can solve the problems of small mass per unit area, problems of battery safety, reduction of battery energy density, etc., so as to increase the content of active substances and reduce internal short circuits. Risk, the effect of alleviating heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

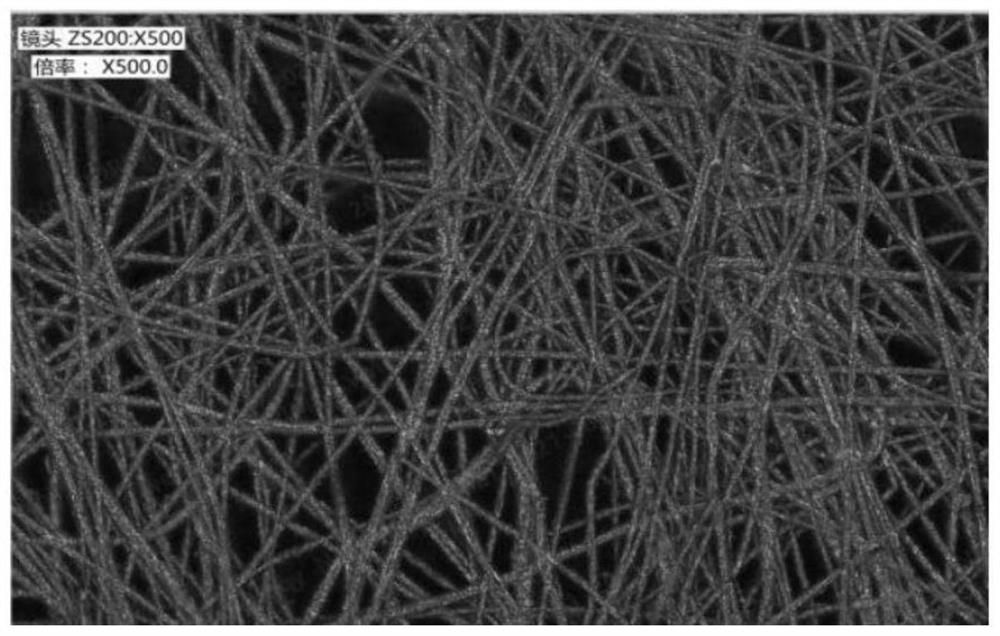

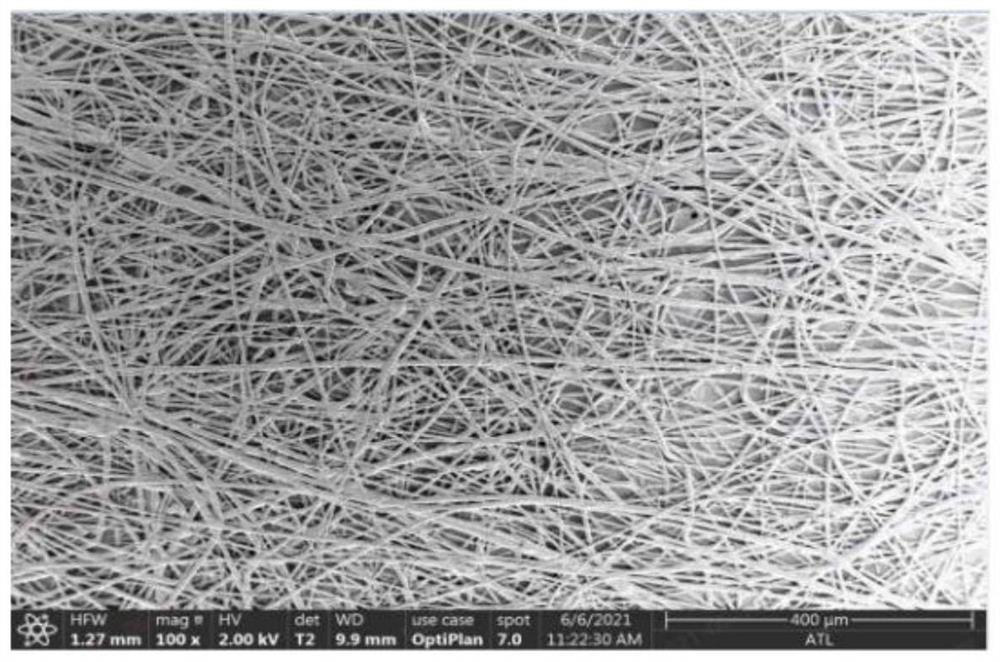

[0033] The present invention also provides the preparation method of the current collector described in the above technical solution, comprising the following steps:

[0034] A conductive metal layer is deposited on the surface and pore structure of a liquid crystal polymer modified fiber cloth substrate with a porous structure to obtain a current collector.

[0035] In the present invention, unless otherwise specified, all preparation raw materials are commercially available products well known to those skilled in the art.

[0036] Before deposition, in the present invention, the liquid crystal polymer modified fiber cloth substrate with porous structure is preferably pretreated, and the pretreatment preferably includes degreasing, roughening and activation in sequence; The process of oil and roughening is not particularly limited, and it can be carried out by a process well known to those skilled in the art. In the present invention, the activation solution used for the act...

Embodiment 1~4

[0055] The liquid crystal polymer non-woven fabrics of the Vecrus series of Japan Kuraray Company, with the grades of MBBK4F-F (Example 1) and MBBK6F-F (Examples 2-4), were successively degreasing, roughening and activating to obtain pre-preg. The treated liquid crystal polymer (LCP) non-woven fabric;

[0056] The liquid crystal polymer non-woven fabric is placed in an electroless plating solution (including 6g / L of anhydrous copper sulfate, 8.5g / L of formaldehyde, 5g / L of complexing agent (mass ratio of 1.3:1 sodium tartrate and Disodium EDTA), 0.041g / L thiourea, and sodium hydroxide as a pH adjuster to adjust the pH value of the electroless plating solution to 11), after electroless plating at 60 °C for 1 min, rinse with deionized water, take out and place in 75 ° C, drying under the hot pressing condition of 2 kg / square inch to obtain a current collector (metallized polymer-based non-woven fabric);

Embodiment 5

[0058] The Vecrus series of Japan Kuraray Company is a liquid crystal polymer non-woven fabric with the grade of MBBK4F-F. The conventional vacuum magnetron sputtering process is used to coat a layer of nickel metal on the surface of the non-woven fabric with a thickness of 0.1um;

[0059] The liquid crystal polymer non-woven fabric is placed in the electroplating solution aqueous solution, and the electroplating solution contains 70g / L of copper pyrophosphate, 300g / L of potassium pyrophosphate, 15g / L of citric acid and 3ml / L of ammonia water, adjusted to PH to about 7.5, after electroplating at 50°C for 1min, washed with deionized water, taken out and dried at 75°C, under hot pressing conditions of 2 kg / square inch, to obtain a current collector (metallized polymer-based non-woven fabric) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com