Gypsum mold precise casting method and device for magnesium alloy casting

A technology of precision casting and gypsum molding, which is applied in the field of gypsum molding precision casting of magnesium alloy castings, can solve the problem of unsolved magnesium alloy flame retardants, etc., and achieve the effects of facilitating shrinkage, reducing shrinkage porosity, and improving mold filling ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A gypsum-type precision casting method for magnesium alloy castings, using the same material casting model and airway model, the airway model and the casting model are connected using a foam ceramic block; the foam ceramic block is a porous foam corundum ceramic block. The foam ceramic block is placed at the position where the molten metal arrives at the end, and plays an exhaust role in the pouring process to prevent the mold from suffocating.

[0051] When making the plaster mold, the casting model and the airway model are placed in advance, and when the casting model and the airway model are melted, the airway will form naturally; both the casting model and the airway model are preferably wax models.

[0052] The magnesium alloy is poured into a mold under a negative pressure of 2KPa (absolute pressure), and after the pouring is completed, it is pressurized and solidified or solidified under atmospheric conditions. When the negative pressure condition is released or ...

Embodiment 2

[0071] A gypsum type precision casting method for magnesium alloy castings, comprising the following steps:

[0072] 1) Using casting simulation technology, design the air channel model for heat dissipation;

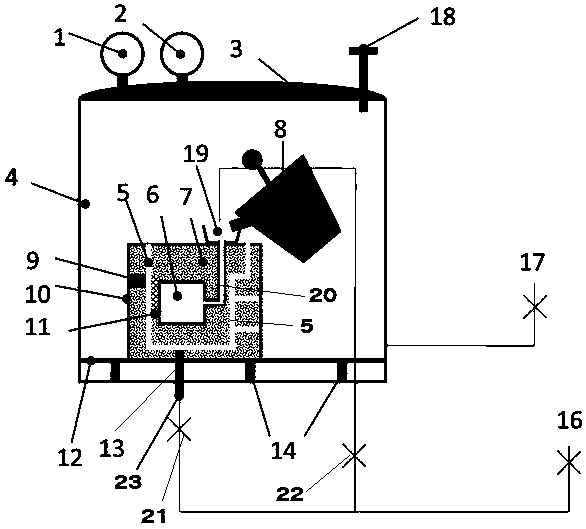

[0073] 2) Make casting wax molds, pouring system wax molds and airway wax molds, and cast casting wax molds, pouring system wax molds, foam ceramic blocks 11 soaked in wax, airway wax molds and airway nozzle wax molds Bonding into a wax tree, the wax tree is placed in the cover box 10 of the gypsum mold;

[0074] 3) Add 10% of 100-mesh graphite particles and 2% of boric acid to the casting gypsum powder, and add 25% of water to prepare gypsum slurry;

[0075] 4) Put the casing 10, the assembled wax tree and the bottom plate 12 into the pressure tank, and connect the vent pipe nozzle wax mold to the pressurized air inlet 23 of the pressure tank; vacuumize to make the pressure tank pressure 10 2 -10 3 Pa, the gypsum slurry was stirred under vacuum for 5-20 minutes, and ...

Embodiment 3

[0089] A gypsum type precision casting method for magnesium alloy castings, comprising the following steps:

[0090] 1) Using casting simulation technology, design the air channel model for heat dissipation;

[0091] 2) Make casting wax molds, pouring system wax molds and airway wax molds, and cast casting wax molds, pouring system wax molds, foam ceramic blocks 11 soaked in wax, airway wax molds and airway nozzle wax molds Bonding into a wax tree, the wax tree is placed in the cover box 10 of the gypsum mold;

[0092] 3) Add 6% of 100-mesh graphite particles and 5% of boric acid to casting gypsum powder, and add 30% of water to prepare gypsum slurry;

[0093] 4) Put the casing 10, the assembled wax tree and the bottom plate 12 into the pressure tank, and connect the vent pipe nozzle wax mold to the pressurized air inlet 23 of the pressure tank; vacuumize to make the pressure tank pressure 10 2 -10 3 Pa, the gypsum slurry was stirred under vacuum for 10 minutes, and then th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com