Intelligent humidifying brick

A humidity-conditioning and intelligent technology, applied in applications, household appliances, clay products, etc., can solve the problems of humidity-conditioning bricks that absorb and release large amounts of moisture, affect the humidity-conditioning performance of materials, and require higher production equipment. The effect of intelligently adjusting air humidity and meeting the requirements of transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0044] (1) Take sepiolite clay (sepiolite), glass powder and powder according to the mass percentage in Table 1, add water with 5% powder mass, and ball mill for 2 hours in a planetary ball mill to obtain a uniform mixture Powder;

[0045] (2) Add the mixed powder into the mould, cloth (pave) and press to form under 12MPa. Dry the green body in a blast drying oven according to the process of 40°C for 4 hours and 70°C for 2 hours, with a thickness of 5mm;

[0046] (3) Put the dried green body into a muffle furnace and fire it at 650° C. for 40 minutes.

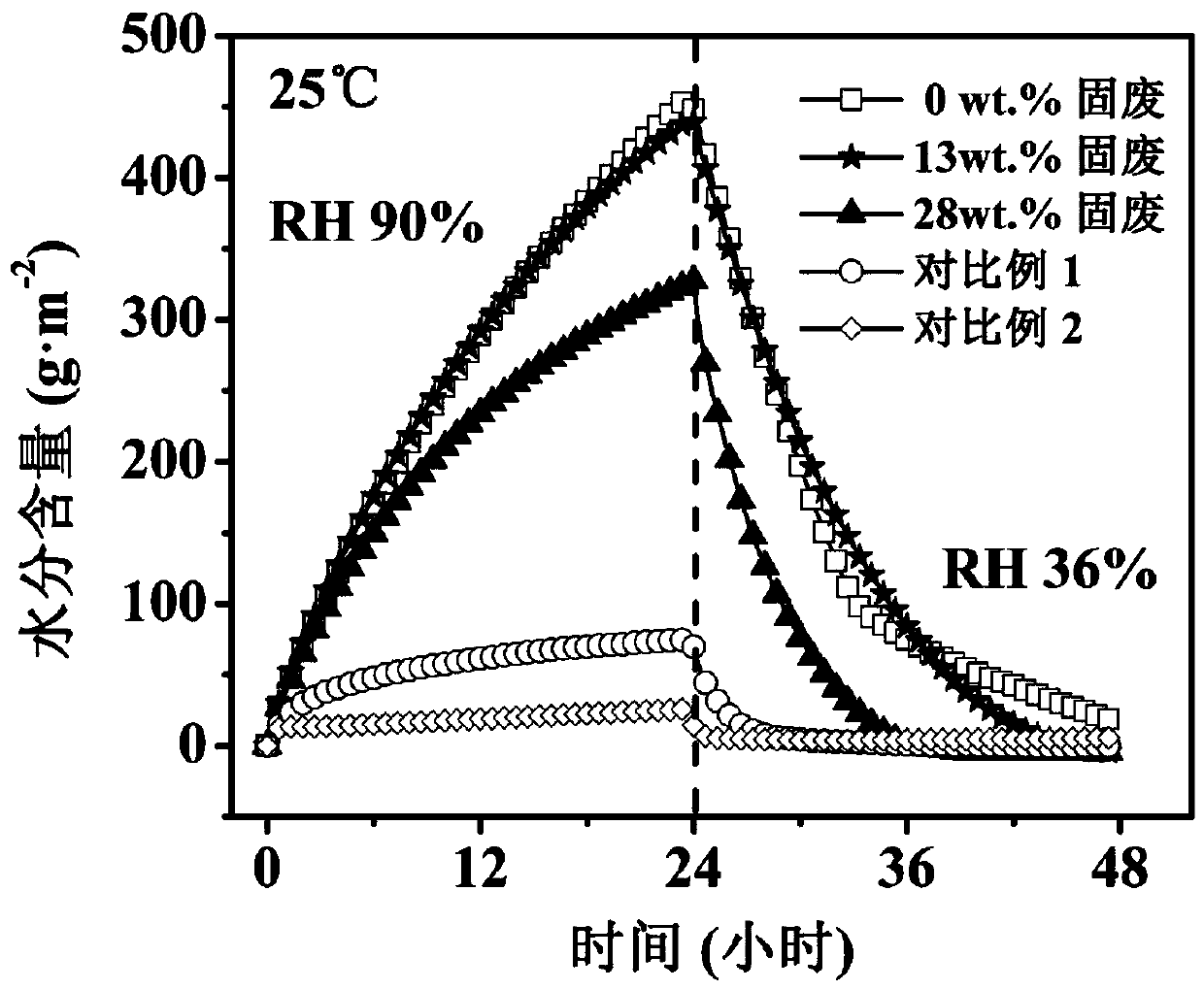

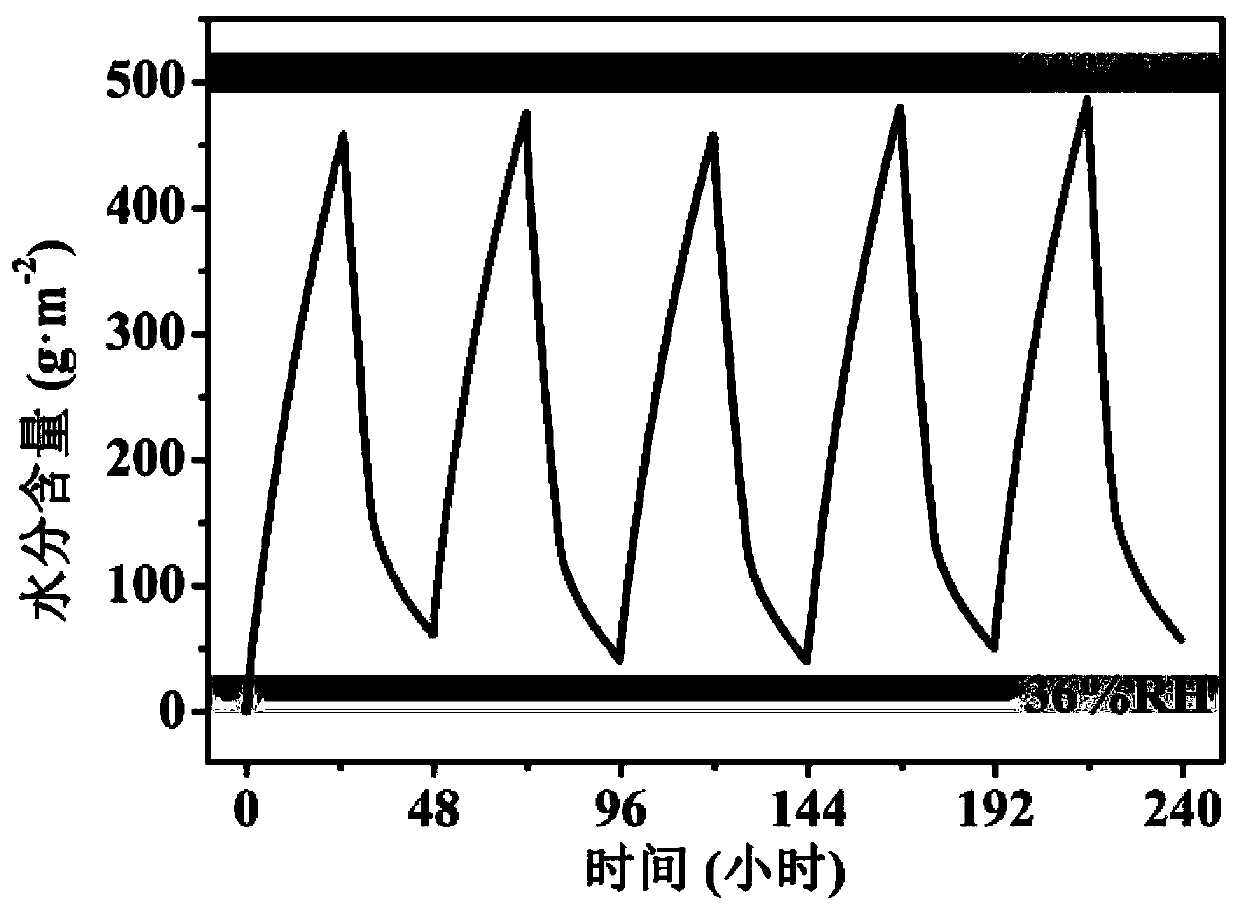

[0047] The flexural strength of the intelligent humidity-adjusting bricks obtained in Examples 1-3 is shown in Table 1, and the flexural strength of the bricks tends to increase with the increase of the amount of glass powder added. Then wrap the intelligent humidity-adjusting brick with aluminum foil, and only expose the upper surface. Under the condition of 25°C, absorb and dehumidify in the environment of 90% and 36% humid...

Embodiment 4-6

[0051] (1), sepiolite clay and glass powder are weighed according to the mass percentage in Table 2, the main ingredient sepiolite: glass powder mass ratio is 4:1, add 10% water of powder quality, in the planetary formula Ball milling in a ball mill for 4 hours to obtain a uniform mixed powder;

[0052] (2) Add the mixed powder into the mould, cloth, press and form at 20MPa. Dry the green body in a blast drying oven according to the process of 40°C for 4 hours and 70°C for 2 hours, with a thickness of 5mm;

[0053] (3) Put the dried green body into a muffle furnace, and fire at 600°C, 700°C, and 800°C for 60 minutes.

[0054] The flexural strength of the intelligent humidity-adjusting brick obtained in this embodiment is shown in Table 2. As the firing temperature increases, the flexural strength of the brick tends to increase. Then wrap the intelligent humidity-adjusting brick with aluminum foil, and only expose the upper surface. Under the condition of 25°C, absorb and deh...

Embodiment 7-9

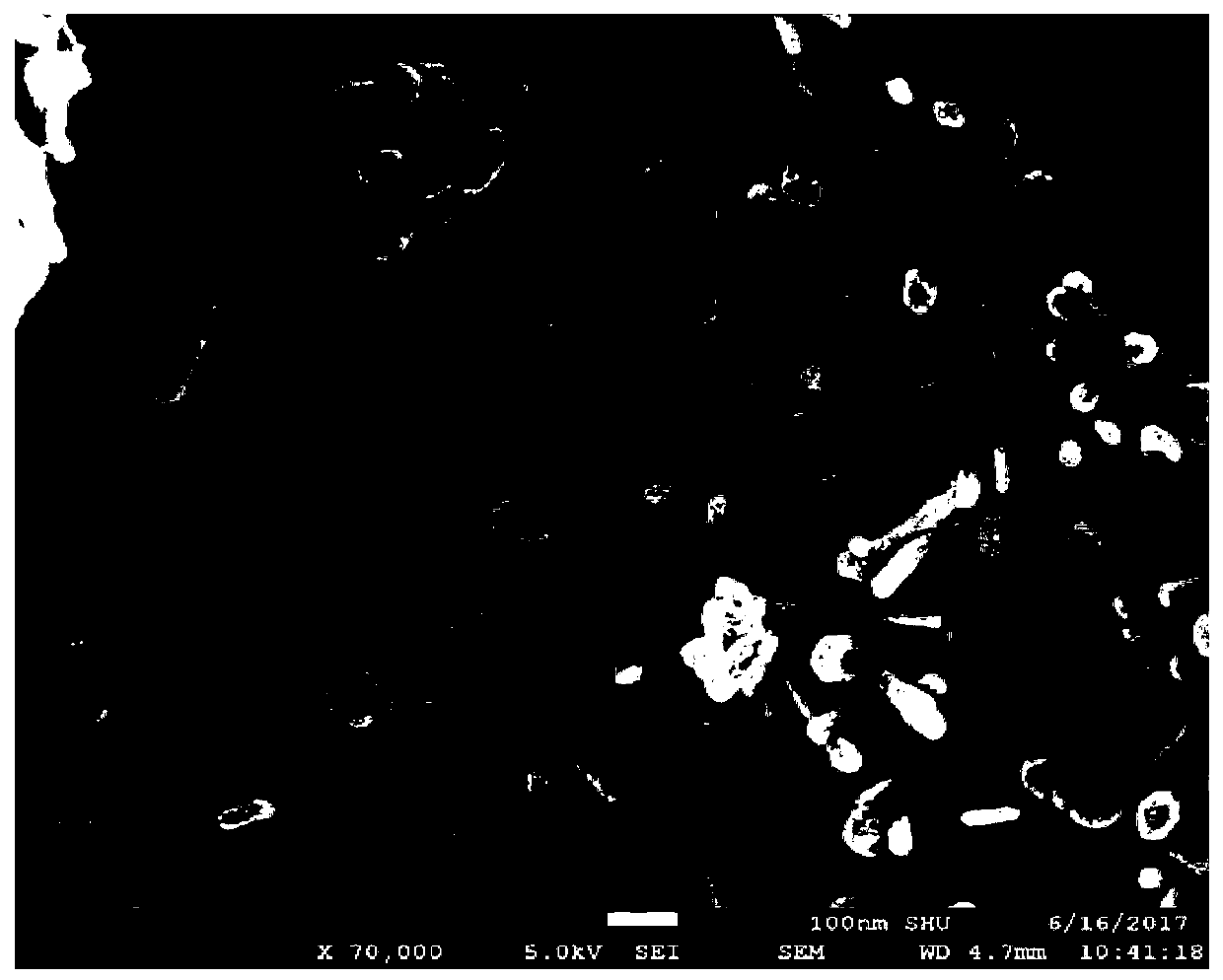

[0058] (1), take sepiolite clay (sepiolite), glass powder and solid waste according to the mass percentage in Table 3 and weigh the powder, sepiolite: glass powder mass ratio is 4:1, add powder mass 10% water, ball milled in a planetary ball mill for 6 hours to obtain uniform raw material powder 1;

[0059] (2), after weighing attapulgite: microsilica fume: fly ash according to the mass percentage, add water with 10% powder mass, and ball mill in a planetary ball mill for 6 hours to obtain uniform raw material powder 2;

[0060] (3) Add the raw material powder 1 and the raw material powder 2 into the mold respectively, spread the material in layers (layered material spreading), and press to form at 20 MPa. Dry the green body in a blast drying oven according to the process of 40°C for 4 hours and 70°C for 2 hours, with a total thickness of 5mm;

[0061] (4) Put the dried green body into a muffle furnace and fire at 700°C for 90 minutes.

[0062] The flexural strength of the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com