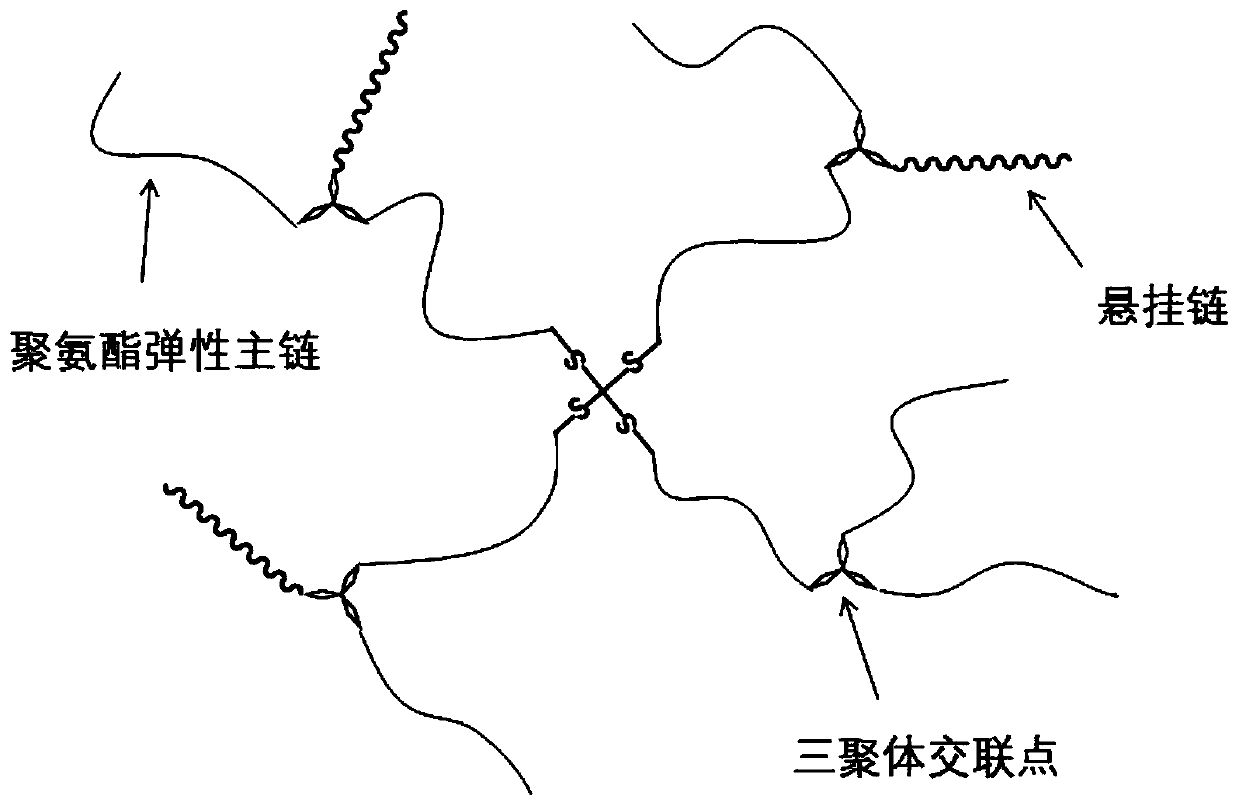

High-temperature-resistant wide-temperature-range high-damping polyurethane elastomer material and preparation method thereof

A technology of polyurethane elastomer and high temperature resistance, which is applied in the field of damping materials, can solve the problems of further improvement of mechanical properties and high temperature resistance, and achieve the effects of widening the damping temperature range, improving damping performance, and improving damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

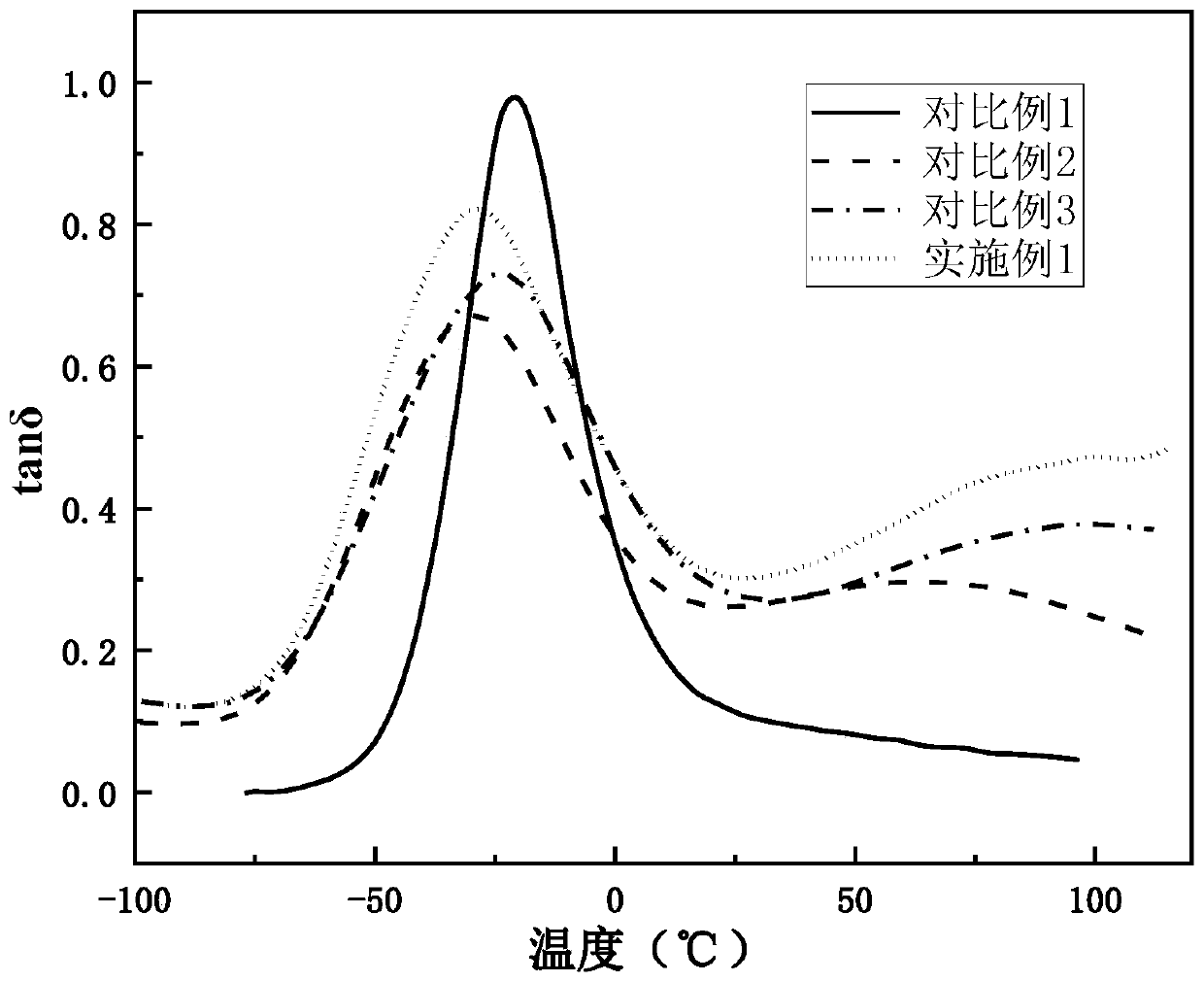

Examples

Embodiment 1

[0048] A method for preparing a high-temperature-resistant high-damping elastomer based on dynamic covalent bonds and suspension chains, comprising the following process steps:

[0049] (1) In terms of weight fraction, 20 parts of polybutylene adipate (molecular weight: 2000) was stirred at 110°C while vacuuming to remove water for 2 hours. After the water removal was completed, the temperature was lowered to 75°C and N 2 Protection, add 4 parts of isophorone diisocyanate and 0.02 parts of catalyst dibutyltin dilaurate, maintain the temperature at 75 ° C, stir for 4 hours to obtain a prepolymer, N 2 Save under atmosphere;

[0050] (2) In terms of weight fraction, 2 parts of 4,4'-diaminodiphenyl disulfide (DTDA) were dissolved in N,N-dimethylformamide and added to the prepolymer, and reacted at 70°C for 1 hour to obtain Polyurethane prepolymer after chain extension with disulfide bond small molecules;

[0051] (3) by weight fraction, in N 2 Under the protection of atmosphere...

Embodiment 2

[0054] A method for preparing a high-temperature-resistant high-damping elastomer based on dynamic covalent bonds and suspension chains, comprising the following process steps:

[0055] (1) In terms of weight fraction, 20 parts of polybutylene adipate (molecular weight: 2000) was stirred at 110°C while vacuuming to remove water for 2 hours. After the water removal was completed, the temperature was lowered to 75°C and N 2 Protection, add 4 parts of isophorone diisocyanate and 0.02 parts of catalyst dibutyltin dilaurate, maintain the temperature at 75 ° C, stir for 4 hours to obtain a prepolymer, N 2 Save under atmosphere;

[0056] (2) In terms of weight fraction, 2 parts of 4,4'-diaminodiphenyl disulfide (DTDA) were dissolved in N,N-dimethylformamide and added to the prepolymer, and reacted at 70°C for 1 hour to obtain Polyurethane prepolymer after chain extension with disulfide bond small molecules;

[0057] (3) by weight fraction, in N 2 Under the protection of the atmosp...

Embodiment 3

[0060] A method for preparing a high-temperature-resistant high-damping elastomer based on dynamic covalent bonds and suspension chains, comprising the following process steps:

[0061] (1) In terms of weight fraction, 20 parts of polybutylene adipate (molecular weight: 2000) was stirred at 110°C while vacuuming to remove water for 2 hours. After the water removal was completed, the temperature was lowered to 75°C and N 2 Protection, add 4 parts of isophorone diisocyanate and 0.02 parts of catalyst dibutyltin dilaurate, maintain the temperature at 75 ° C, stir for 4 hours to obtain a prepolymer, N 2 Save under atmosphere;

[0062] (2) In terms of weight fraction, 4 parts of 4,4'-diaminodiphenyl disulfide (DTDA) were dissolved in N,N-dimethylformamide and added to the prepolymer, and reacted at 70°C for 1 hour to obtain Polyurethane prepolymer after chain extension with disulfide bond small molecules;

[0063] (3) by weight fraction, in N 2 Under the protection of atmosphere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com