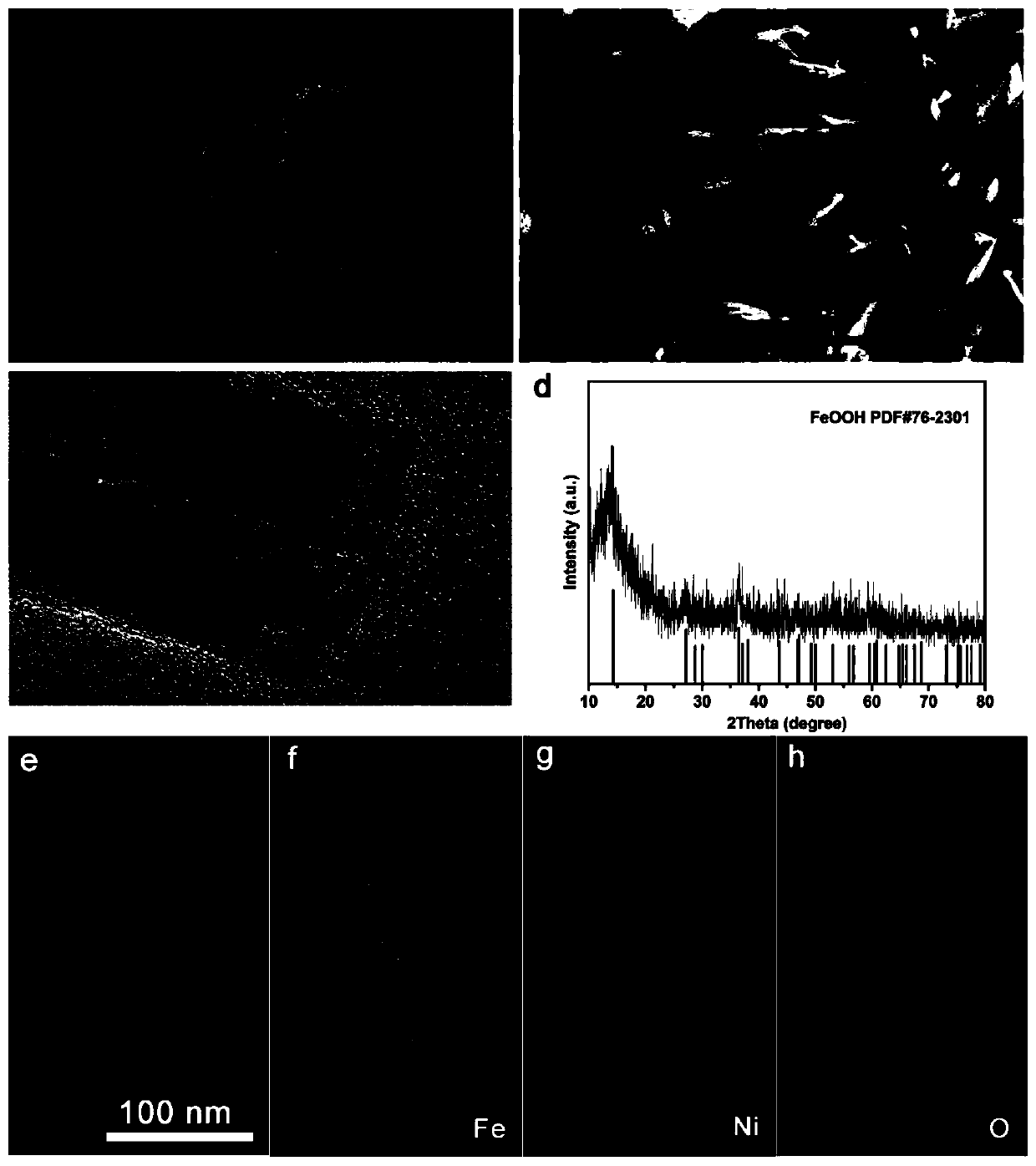

Preparation method and applications of Ni-doped FeOOH/NF synthesized by using millisecond laser direct writing technology

A laser direct writing technology, applied in the field of nickel foam, achieves the effect of convenient operation, easy control, and high OER catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Configure 50 mL of hydrochloric acid solution with a concentration of 3 mol / L: Measure 12.99 mL of 36% hydrochloric acid in a 100 mL beaker with a graduated cylinder, then add 37.01 mL of deionized water, and stir evenly with a glass rod;

[0023] (2) Get a foam nickel of 2cm*2cm, soak the foam nickel in the prepared solution of step (1) for 30min and take it out, then rinse the foam nickel five times with deionized water to wash off the hydrochloric acid on the surface;

[0024] (3) Configure 30 mL of FeCl with a concentration of 0.036 mol / L 2 4H 2 O solution: Weigh 214.6mgFeCl 2 4H 2 O was dissolved in 30mL of deionized water, and stirred with a glass rod until the powder was completely dissolved to obtain an iron salt solution;

[0025] (4) placing the foamed nickel obtained in step (2) in the prepared iron salt solution of step (3) to form a sample;

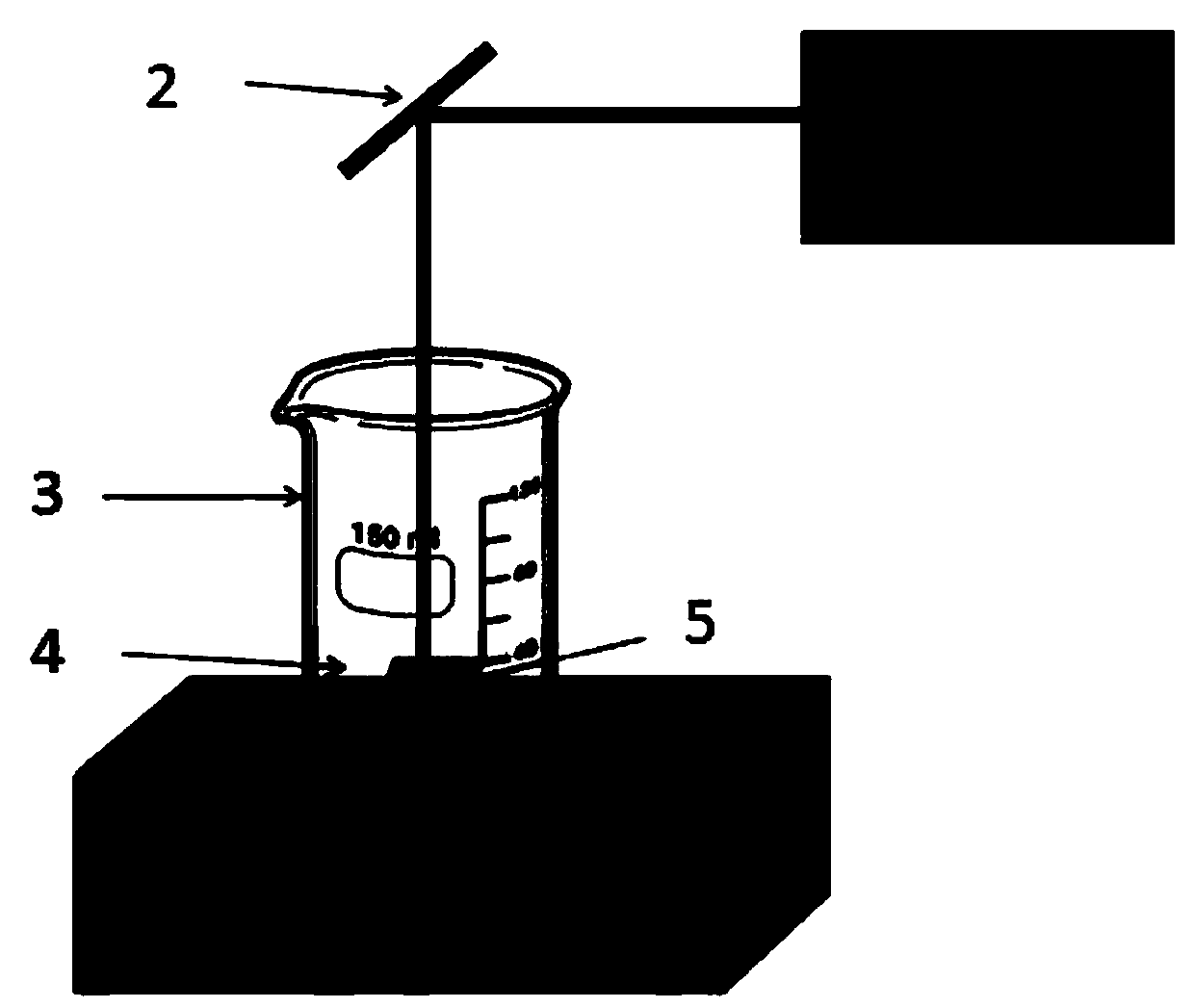

[0026] (5) Place the sample obtained in step (4) on an electric translation stage, then irradiate the sample...

Embodiment 2

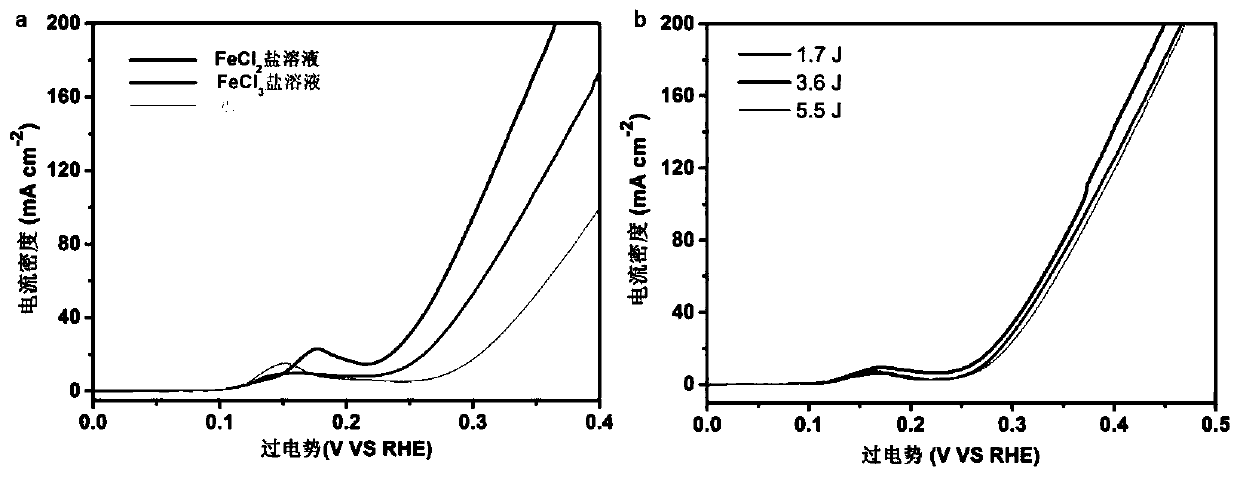

[0028] Its basic steps are the same as in Example 1, except that in step (3), the concentration of configuration 30mL is 0.036mol / L of FeCl 3 ·6H 2 O solution: weigh 291.7 mg of FeCl 3 ·6H 2 O was dissolved in 30 mL of deionized water and stirred with a glass rod until the powder was completely dissolved.

Embodiment 3

[0030] The basic steps are the same as those in Example 1, except that in step (5), the energy of the millisecond laser is 1.7J.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com