Supported transition metal carbide as well as preparation method and application thereof

A technology of transition metals and transition metal salts, applied in chemical instruments and methods, catalyst activation/preparation, water treatment of special compounds, etc., can solve problems such as ozone oxidation reactions that have not yet been seen, and achieve environmental and energy problems and high effluent quality , the effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

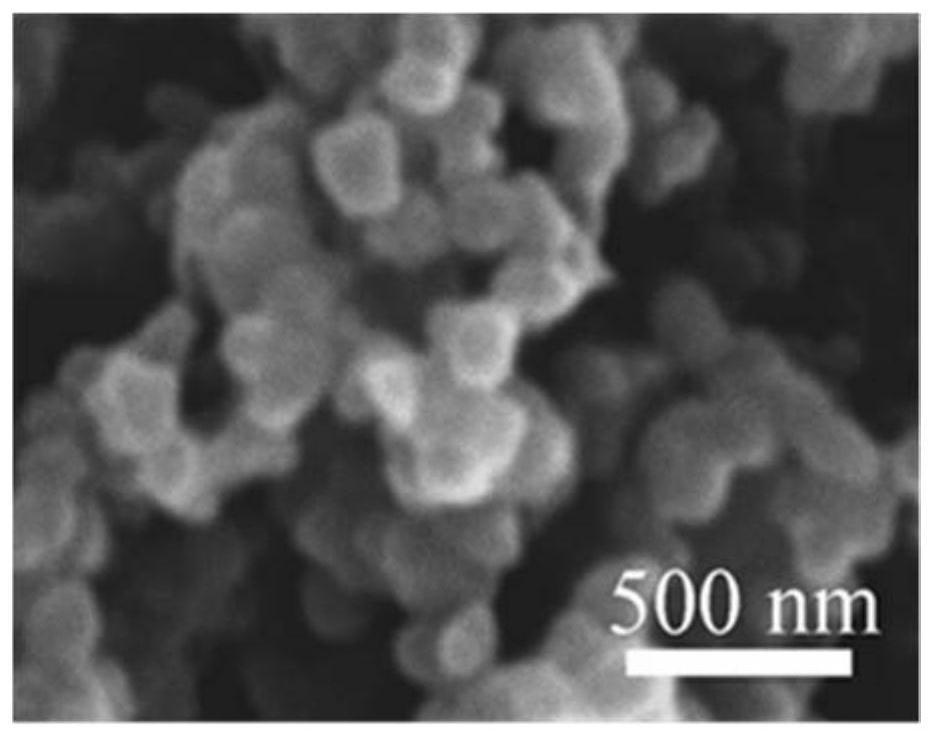

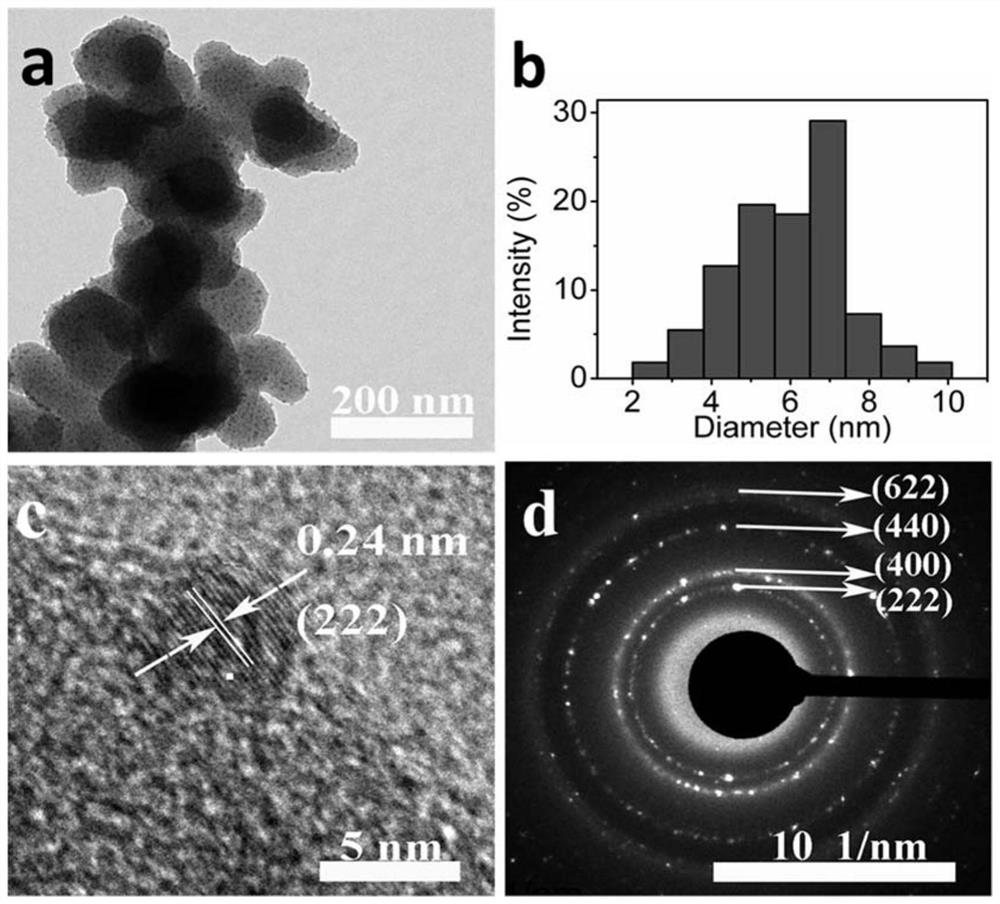

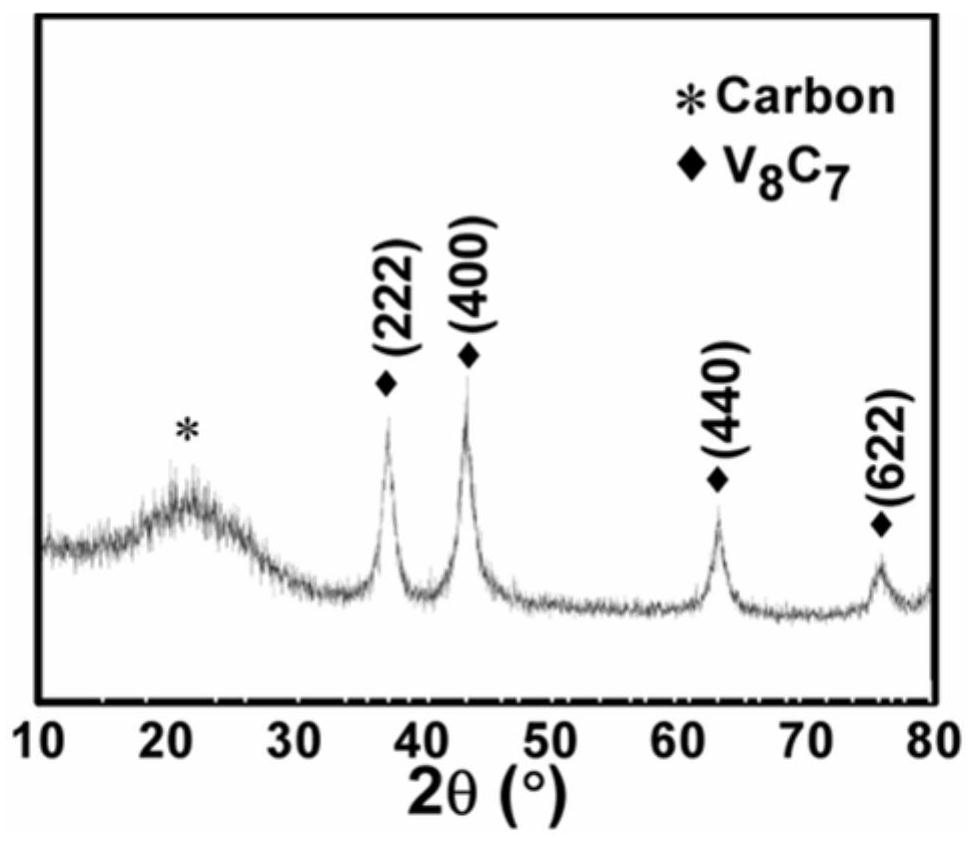

[0059] Embodiment 1, preparation and catalytic oxidation reaction of supported transition metal carbides of the present invention

[0060] Supported transition metal carbide V 8 C 7 The preparation of / CS: reactant 0.47g ammonium metavanadate (NH 4 VO 3 ) and 4.0g glucose (C 6 h 12 o 6 ) was added to 40ml of deionized water at 60°C, and stirred continuously at constant temperature for 1h. The mixture obtained is added into a 60ml hydrothermal reaction kettle, and the stainless steel jacket of the hydrothermal reaction kettle is installed. The hydrothermal reactor was placed in an oven at 160° C. for 15 h. After natural cooling, the mixture was alternately washed several times with deionized water and ethanol, and centrifuged to obtain a brown precipitate (metal organic framework precursor). The precipitate was dried in a vacuum oven at 70°C, and the obtained dried precipitate was loaded into a corundum boat and placed in the center of a tube furnace. In the Ar flow of...

Embodiment 2

[0062] Example 2, preparation of supported transition metal carbides of the present invention and catalytic oxidation reaction Supported transition metal carbides W 2 The preparation of C / CS: reactant 1.07g phosphotungstic acid (H 3 PW 12 o 40 ) and 4.0g glucose (C 6 h 12 o 6 ) was added to 40ml of deionized water at 60°C, and stirred continuously at constant temperature for 1h. The mixture obtained is added into a 60ml hydrothermal reaction kettle, and the stainless steel jacket of the hydrothermal reaction kettle is installed. The hydrothermal reactor was placed in an oven at 160° C. for 15 h. After natural cooling, the mixture was alternately washed several times with deionized water and ethanol, and centrifuged to obtain a brown precipitate (metal organic framework precursor). The precipitate was dried in a vacuum oven at 70°C, and the obtained dried precipitate was loaded into a corundum boat and placed in the center of a tube furnace. In the Ar flow of 40ml / min, ...

Embodiment 3

[0064] Example 3, preparation and catalytic oxidation reaction of supported transition metal carbides of the present invention

[0065] Supported transition metal carbide Fe 3 The preparation of C / CS: reactant 1.08g ferric nitrate (Fe(NO 3 ) 3 ) and 4.0g glucose (C 6 h 12 o 6 ) was added to 40ml of deionized water at 60°C, and stirred continuously at constant temperature for 1h. The mixture obtained is added into a 60ml hydrothermal reaction kettle, and the stainless steel jacket of the hydrothermal reaction kettle is installed. The hydrothermal reactor was placed in an oven at 160° C. for 15 h. After natural cooling, the mixture was alternately washed several times with deionized water and ethanol, and centrifuged to obtain a brown precipitate (metal organic framework precursor). The precipitate was dried in a vacuum oven at 70°C, and the obtained dried precipitate was loaded into a corundum boat and placed in the center of a tube furnace. In an Ar flow of 40ml / min, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com