Method for processing copper-cobalt ore

A technology of copper-cobalt ore and copper-cobalt, which is applied in the direction of solid separation and flotation, can solve the problems of reduced recovery rate, increased slag viscosity, and high MgO content of flotation concentrate, and achieves the effect of small environmental impact and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

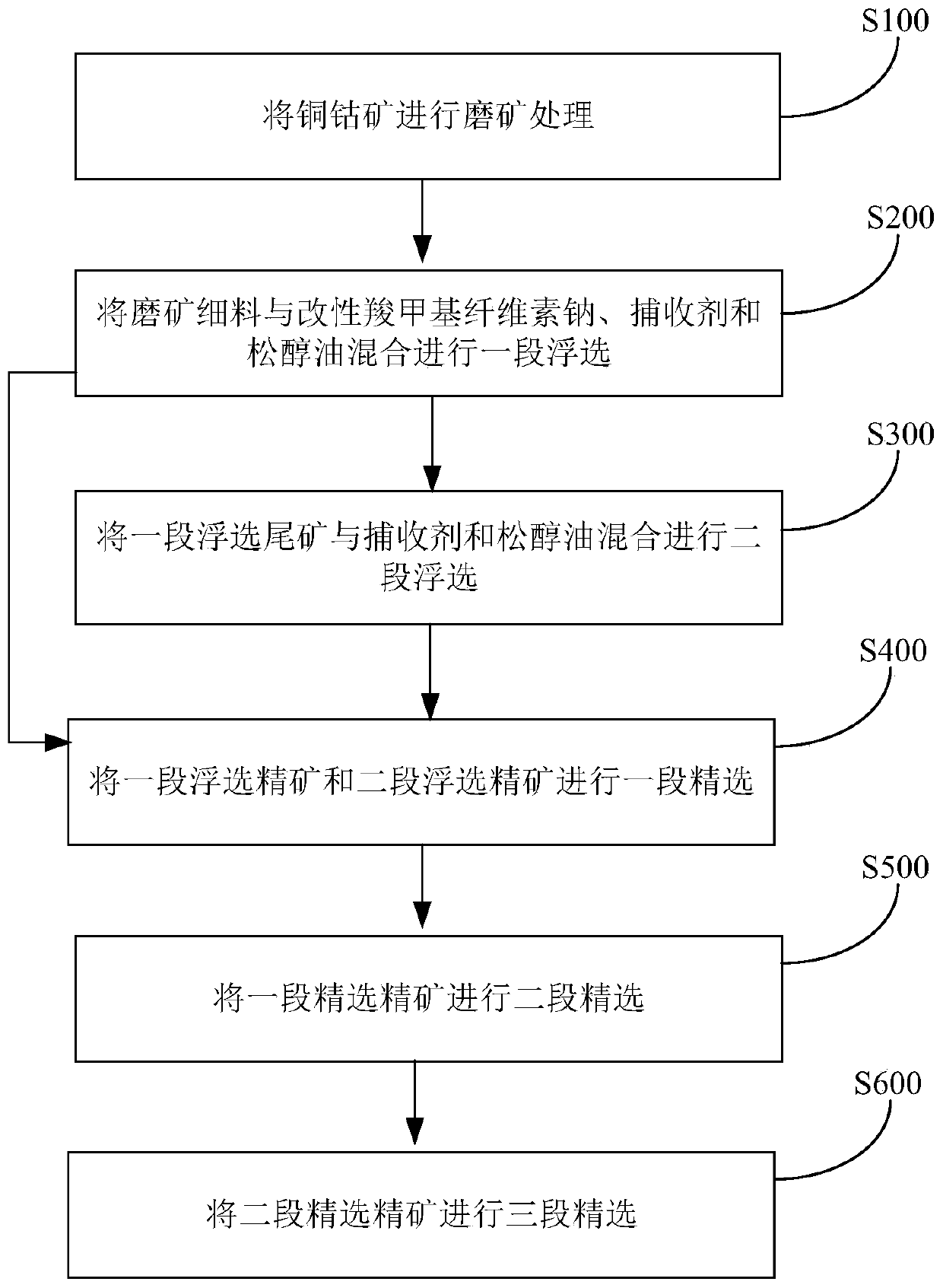

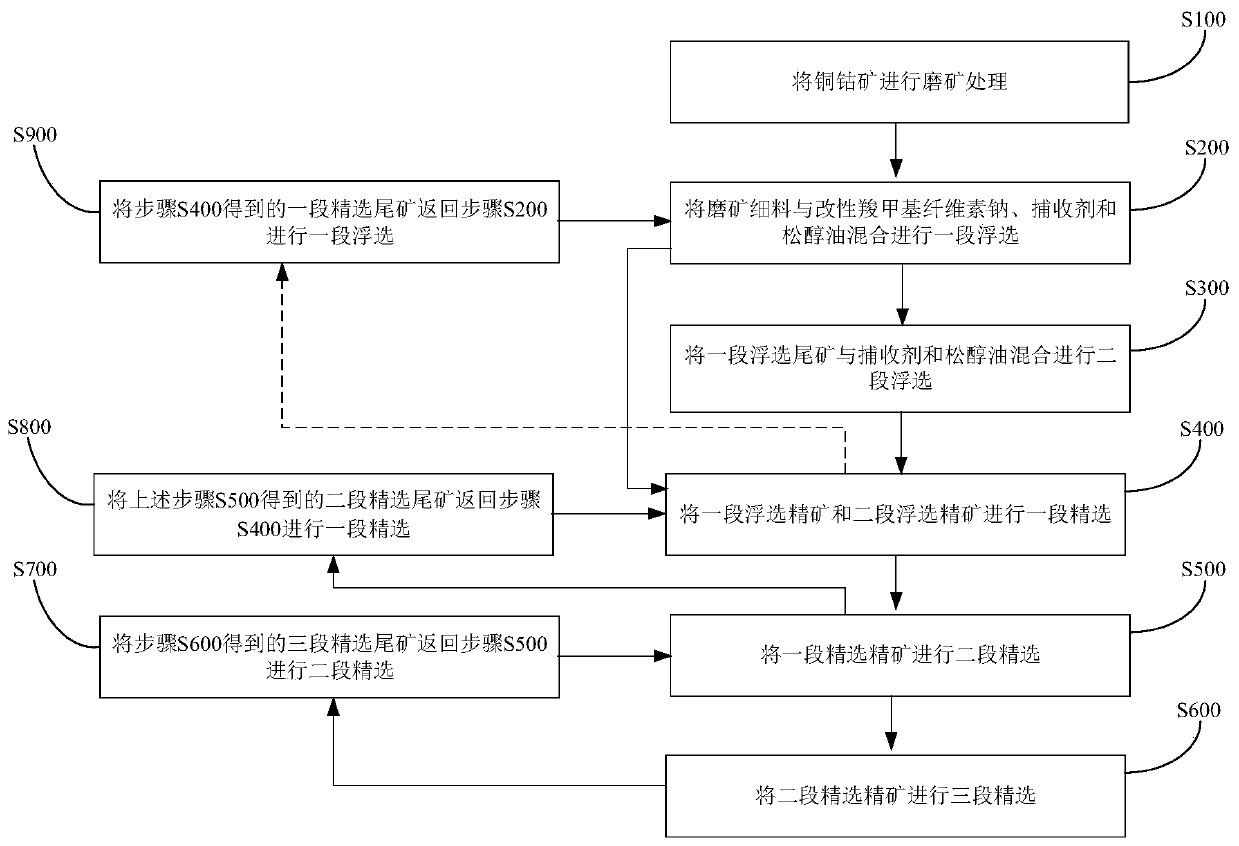

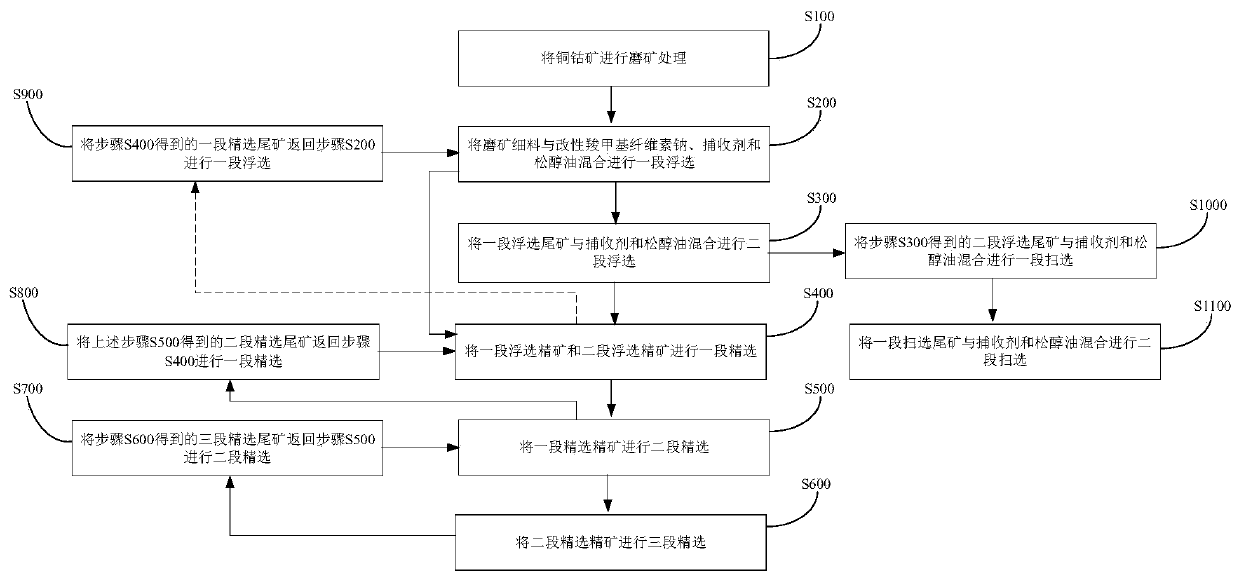

[0064] see Figure 5 Shown is a flow chart of a method for processing copper-cobalt ore. The grade of copper in a copper-cobalt ore is 5.40wt%, the grade of cobalt is 0.060wt%, and the grade of magnesium is 8.50wt%.

[0065] (1) Grinding the copper-cobalt ore with a ball mill, 60% of the obtained grinding fines have a particle size not higher than 0.074mm;

[0066] (2) Mix the grinding fines with modified sodium carboxymethyl cellulose, butyl xanthate and terpineol oil to carry out one-stage flotation, so as to obtain one-stage flotation concentrate and one-stage flotation tailings, wherein, based on 1t For copper cobalt ore, the consumption of modified sodium carboxymethyl cellulose is 500g, the consumption of butyl xanthate is 80g, the consumption of terpineol oil is 40g, and the one-stage flotation time is 5min;

[0067] (3) Mix the first-stage flotation tailings with butyl xanth and terpineol oil for second-stage flotation, so as to obtain the second-stage flotation conc...

Embodiment 2

[0080] see Figure 5 Shown is a flow chart of a method for processing copper-cobalt ore. The copper grade in a copper-cobalt ore is 5.45wt%, the cobalt grade is 0.066wt%, and the magnesium grade is 8.58wt%.

[0081] (1) Grinding the copper-cobalt ore with a ball mill, 60% of the obtained grinding fines have a particle size not higher than 0.074mm;

[0082] (2) Mix the grinding fines with modified sodium carboxymethyl cellulose, butyl xanthate and terpineol oil to carry out one-stage flotation, so as to obtain one-stage flotation concentrate and one-stage flotation tailings, wherein, based on 1t Copper-cobalt ore, the consumption of modified sodium carboxymethyl cellulose is 300g, the consumption of butyl xanthate is 80g, the consumption of terpineol oil is 40g, and the flotation time of one stage is 5min;

[0083] (3) Mix the first-stage flotation tailings with butyl xanth and terpineol oil for second-stage flotation, so as to obtain the second-stage flotation concentrate an...

Embodiment 3

[0096] see Figure 5 Shown is a flow chart of a method for processing copper-cobalt ore. The grade of copper in a copper-cobalt ore is 5.35wt%, the grade of cobalt is 0.056wt%, and the grade of magnesium is 8.28wt%.

[0097] (1) Grinding the copper-cobalt ore with a ball mill, 60% of the obtained grinding fines have a particle size not higher than 0.074mm;

[0098] (2) Mix the grinding fines with modified sodium carboxymethyl cellulose, collector (the mass ratio of butyl xanthate and butyl ammonium black medicine 1:1) and terpineol oil for one-stage flotation, so as to obtain a stage Flotation concentrate and one-stage flotation tailings, wherein, based on 1t of copper-cobalt ore, the dosage of modified carboxymethyl cellulose sodium is 400g, the dosage of collector is 80g, the dosage of terpineol oil is 40g, and the dosage of one-stage flotation The selected time is 5 minutes;

[0099] (3) Mix the first-stage flotation tailings with collector (butyl xanthate and butylammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com