A method for simultaneous preparation of mycelium fiber and ethanol by fungal fermentation of food waste

A technology of food waste and fungi, which is applied in the field of synchronous preparation of mycelium fiber and ethanol by fungal fermentation of food waste, can solve the problems of affecting fermentation efficiency, low utilization rate, and difficulty in oil extraction and recovery, so as to improve separation efficiency and increase additional value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

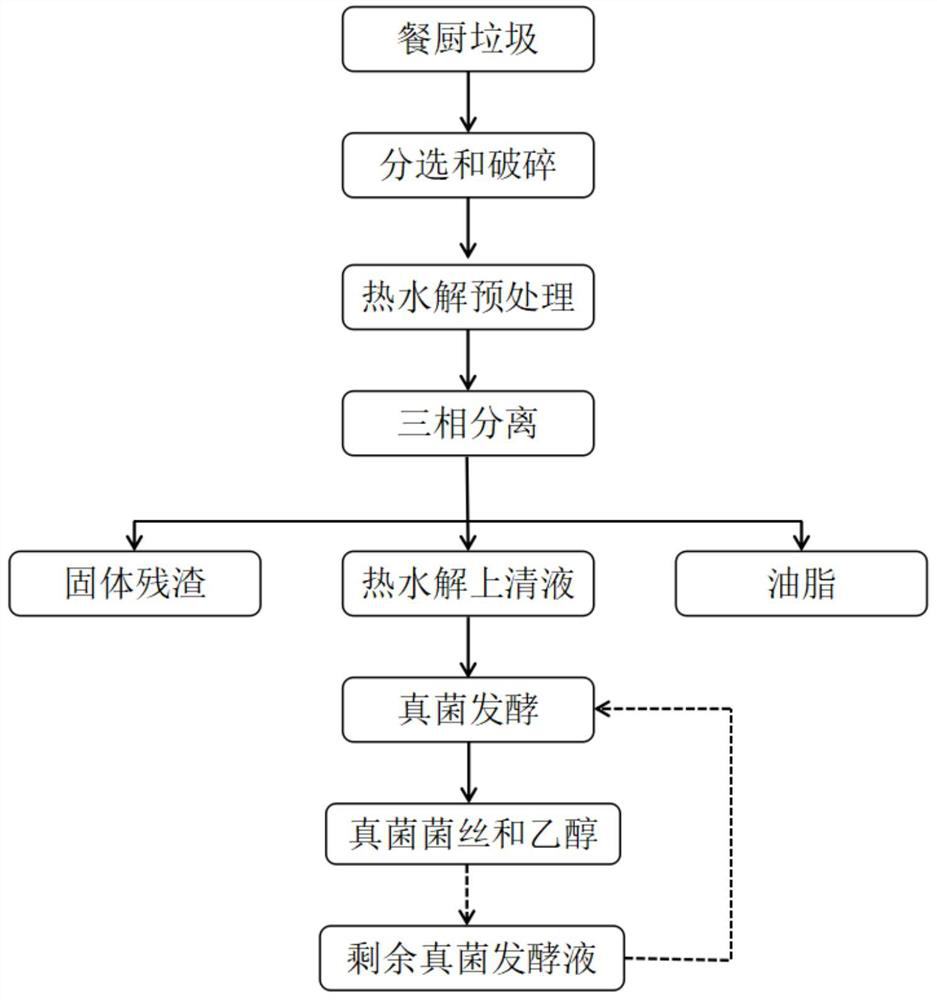

[0025] see figure 1 , figure 1 It is a schematic flowchart of a method for synchronously preparing mycelium fiber and ethanol by fungal fermentation of food waste. This embodiment provides a method for synchronously preparing mycelium fiber and ethanol by fungal fermentation of food waste. The specific process is as follows:

[0026] After draining the kitchen waste from the campus restaurant, sort out impurities such as plastic, metal, fabric, bone and chopsticks, and then perform high-speed mechanical crushing with a speed of 25,000 rpm and a crushing time of 3 minutes. Dilute the homogeneous kitchen waste obtained after crushing with water, adjust the solid content to about 13wt.%, and then perform thermal hydrolysis pretreatment. The pretreatment temperature is 120°C, the treatment time is 1h, the stirring speed is 200rpm, and the reaction is over. Afterwards, the temperature was lowered to 50°C by condensing water. After thermal hydrolysis, the kitchen waste is centrifu...

Embodiment 2

[0028] This embodiment provides a method for synchronously preparing mycelium fiber and ethanol by fungal fermentation of food waste, and the specific process is as follows:

[0029] The food waste fermented liquid that reclaims mycelia fiber and ethanol through a fungus (Aspergillus niger) fermentation in Example 1 is sterilized again, and the food waste COD concentration after one fermentation is 70.8g / L, and the total sugar concentration is 70.8g / L. The remaining fungal fermentation liquid after sterilization was inoculated with Aspergillus niger suspension again for fungal fermentation. After 5 days of shaking culture at 28°C and 150rpm, the concentration of fungal mycelium fibers reached 14.0g / L, and the concentration of ethanol was greater than 6.0g / L.

Embodiment 3

[0031] This embodiment provides a method for synchronously preparing mycelium fiber and ethanol by fungal fermentation of food waste, and the specific process is as follows:

[0032] After the fungal fermentation of the thermal hydrolyzate of food waste is completed, mycelium particles are recovered by vacuum filtration method, and the suction filtration screen is 200 mesh. The recovered mycelium particles are decomposed by adding water. During the decompression process, the concentration of mycelium fibers is 1.0wt.%, the decompression speed is 3500rpm, and the decompression time is 1min. The diluted net concentration is 0.1wt.%. After stirring or bubbling, the mycelium fibers are evenly dispersed. After standing for 10 seconds, the negative pressure generated by the dehydration element under the net is used to filter, so that the mycelium fibers are evenly deposited on the net. On the surface, a paper sheet is formed, and the formed paper sheet is dehydrated by pressure filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com