A kind of mulberry fresh fruit enzyme and preparation method thereof

A technology for mulberries and fresh fruits, applied in the field of beverage processing, can solve the problems of single metabolites, long time consumption, easy generation of miscellaneous bacteria, etc., and achieve the effects of rich aroma, shortening fermentation time, and enriching the product market.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

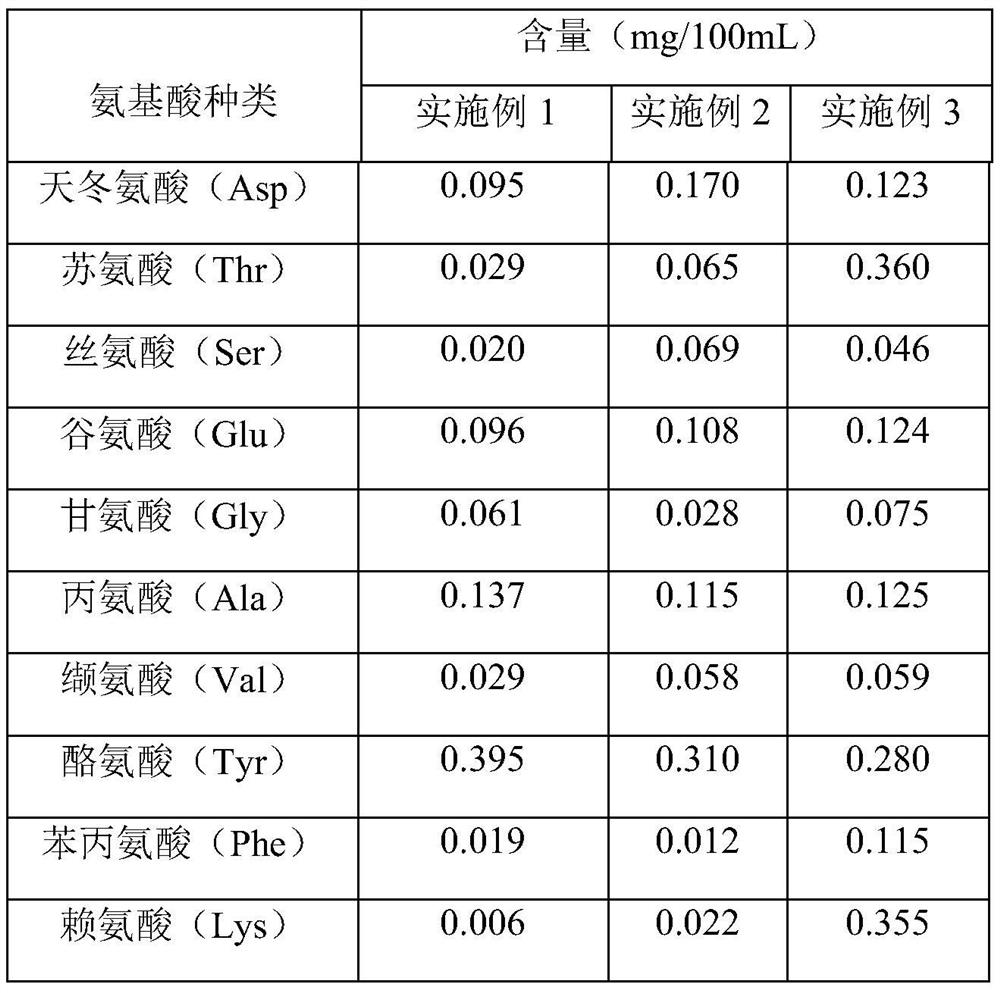

Embodiment 1

[0036] The preparation method of described mulberry fresh fruit enzyme is carried out according to the following steps:

[0037] Take 40L of fresh mulberry juice, press 1×10 6 The ratio of u / t was added with pectinase for enzymatic hydrolysis for 3 hours, then 0.5kg of glucose and 1kg of beef dipping powder were added, and the mixture was evenly mixed.

[0038] The above mixture was placed in a fermenter, sterilized at 115° C. for 15 min, and after the sterilization was completed, it was left to cool naturally.

[0039] Access to the fermentation strain mixture (Streptococcus thermophilus, Continococcus leuencephalon, the mass ratio of the two is 1:1), and ferment for 6 days at 37 ° C under the conditions of 100r / min. The inoculum of the strain mixture is the material 3%, and the number of viable bacteria in the bacterial solution is 3.0×10 8 cfu / mL.

[0040] After the fermentation, the fermented liquid was moved to other containers and matured for 3 months.

[0041] The a...

Embodiment 2

[0047] The preparation method of described mulberry fresh fruit enzyme is carried out according to the following steps:

[0048] Take 40L of fresh mulberry juice, press 2×10 6 The ratio of u / t was added with pectinase for enzymatic hydrolysis for 2 hours, then 1kg of white sugar and 1.5kg of beef dipping powder were added, and the mixture was evenly mixed.

[0049] The above mixture was placed in a fermenter, sterilized at 117° C. for 15 min, and after the sterilization was completed, it was left to cool naturally.

[0050] Access to the fermentation strain mixture (Acetobacter pasteuriana, Lactobacillus, the mass ratio of the two is 1:1), fermented at 39 ° C, 100r / min for 4d, the inoculum of the strain mixture is the material. 4%, the number of viable bacteria in the bacterial solution is 3 × 10 8 cfu / mL.

[0051] After the fermentation, the fermented liquid was moved to other containers and matured for 3 months.

[0052] The after-ripening enzymes were centrifuged and fi...

Embodiment 3

[0058] The preparation method of described mulberry fresh fruit enzyme is carried out according to the following steps:

[0059] Take 40L of fresh mulberry juice, press 5×10 5 In the ratio of u / t, add pectinase for enzymatic hydrolysis for 2 to 4 hours, then add 0.5kg of glucose and 1.5kg of beef dipping powder, and mix evenly.

[0060] The above mixture was placed in a fermenter, sterilized at 120° C. for 15 min, and after the sterilization was completed, it was left to cool naturally.

[0061] The fermented strain mixture (mixture of Continococcus leuencephalae, Acetobacter pasteurii, and Lactobacillus, the mass ratio of the three is 1:1:1), was fermented for 6 days at 37°C and 100 r / min. The inoculation amount of the mixed solution is 3% of the material, and the number of viable bacteria in the bacterial solution is 3×10 8 cfu / mL.

[0062] After the fermentation, the fermented liquid was moved to other containers and matured for 3 months.

[0063] The after-ripening enz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com