Preparation method of L-theanine

A technology of theanine and glutamic acid, which is applied in the field of preparation of L-theanine, can solve the problems of low yield and low safety, and achieve the effects of simple post-processing, improved safety and easy acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

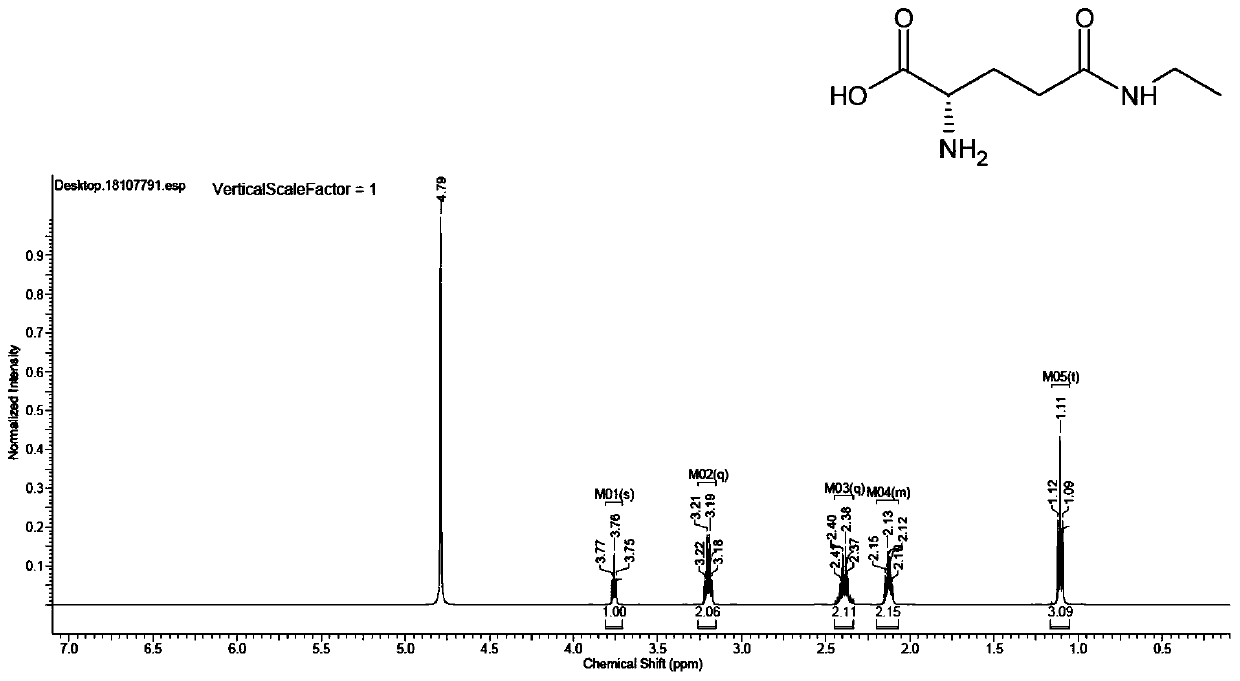

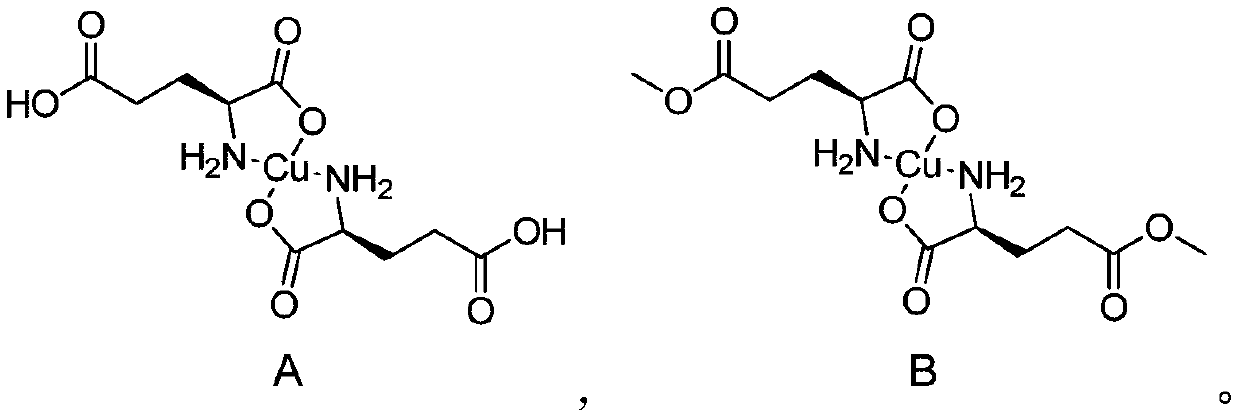

[0053] The reaction scheme of the preparation method of the present embodiment is as follows:

[0054]

Embodiment 1

[0056] The present embodiment provides a kind of preparation method of L-theanine, comprises the following steps:

[0057] (1) Add 20.0g of L-glutamic acid to a 500mL reaction vessel, add 100g of water, start stirring, add the prepared copper acetate aqueous solution dropwise at 30°C, continue to react for 0.5h after the dropwise addition, and then filter under reduced pressure , wash the precipitate with a small amount of water to obtain 22.8 grams of L-copper glutamate chelate (chelate A) crude product;

[0058] Wherein, the preparation method of copper acetate aqueous solution is: stirring and dissolving 16.3g of copper acetate monohydrate in 100g of water.

[0059] (2) Add the L-copper glutamate chelate crude product obtained in step (1) into a 500mL reaction vessel, add 160mL of methanol, add 16.0g of concentrated sulfuric acid with a mass fraction of 98% under stirring conditions, and add 16.0g of concentrated sulfuric acid at 30°C After reacting for 3 hours, the reacti...

Embodiment 2

[0064] The present embodiment refers to the preparation method of Example 1, the difference is only that step (3) is as follows:

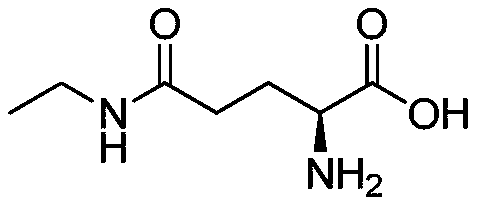

[0065] The L-glutamic acid-5-methyl ester copper chelate crude product obtained in step (2) was added in a 500mL reaction vessel, 180g of water was added, and an aqueous solution of ethylamine (70% by mass) 24.0 g was added dropwise at 30°C. g, after reacting for 3 hours, add 30.3 g of EDTA disodium salt, then raise the temperature of the reaction solution to 60°C for 3 hours, stop the reaction, concentrate the water in the reaction solution to dryness, and obtain crude L-theanine;

[0066] Recrystallize the crude L-theanine with ethanol to obtain L-theanine; the specific recrystallization method includes: adding 160 g of ethanol to the crude L-theanine above, heating to reflux and stirring for 1-2 hours, and filtering while hot, After cooling and crystallization, filter and dry to obtain 19.0 g of L-theanine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com