High-performance water-based drilling fluid for maintaining stable shale strength and preparation method thereof

A water-based drilling fluid and high-performance technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of insufficient performance such as temperature resistance, field application limitations, and high processing costs, etc., to achieve improved shale Stability, maintenance of particle size distribution, effect of improving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

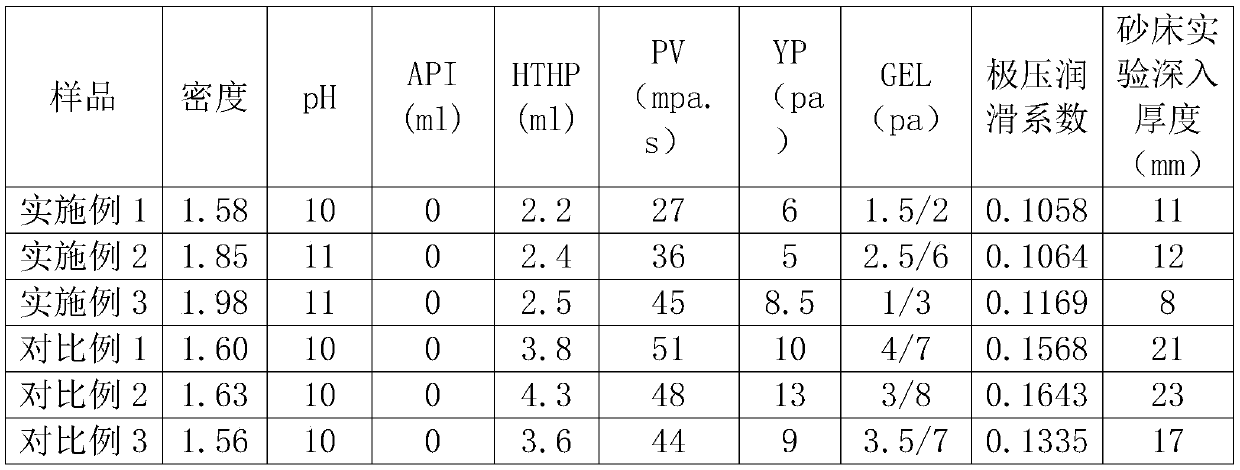

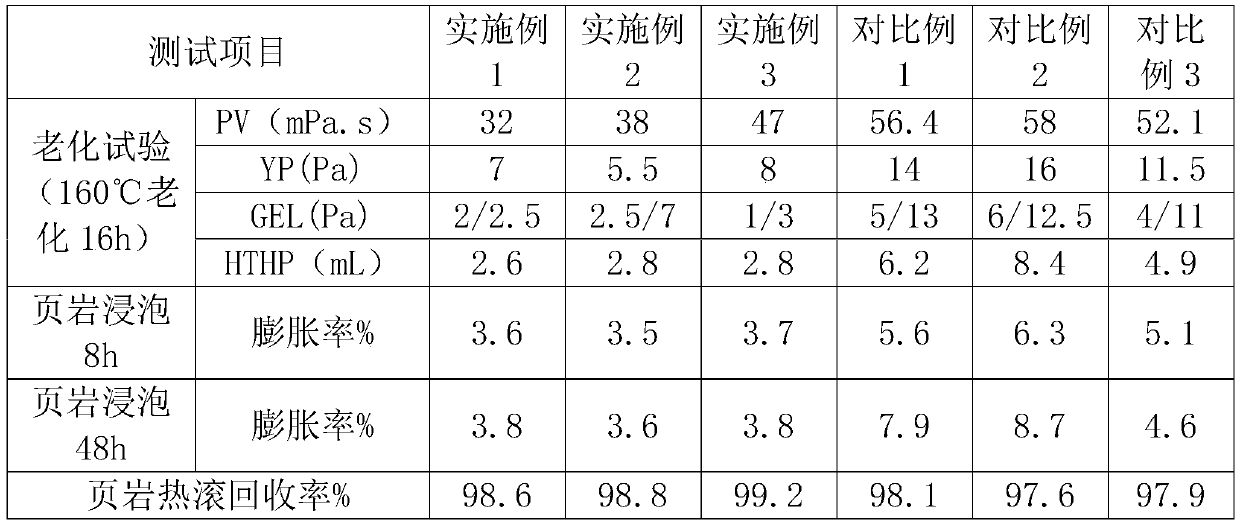

Examples

Embodiment 1

[0029] A high-performance water-based drilling fluid for maintaining stable shale strength, comprising the following raw materials in parts by weight: 8 parts of bentonite for drilling, 0.8 parts of sodium hydroxide, 20 parts of composite plugging agent, 14 parts of fluid loss reducer, polymer 12 parts of alcohol anti-slump agent, 8 parts of long-chain alcohol amine ester extreme pressure friction reducer, 12 parts of potassium chloride, 2 parts of polyamine inhibitor, 260 parts of weighting agent, 400 parts of water;

[0030] The composite plugging agent is a mixture of 16 parts of styrene latex and 4 parts of nano-strengthening agent; the nano-strengthening agent is modified porous SiO 2 Nanoparticles, the particle size range is 100-150nm, the pore size range is 5-10nm, porous SiO 2 C3-C16 groups are grafted on the surface of nanoparticles, the group contains a five-membered ring structure, contains amino and hydroxyl functional groups, and 12% of the hydrogen atoms in the g...

Embodiment 2

[0040]A high-performance water-based drilling fluid that maintains stable shale strength, comprising the following raw materials in parts by weight: 10 parts of bentonite for drilling, 0.9 parts of sodium hydroxide, 24 parts of composite plugging agent, 18 parts of fluid loss reducer, polymer 13 parts of alcohol anti-slump agent, 10 parts of long-chain alcohol amine ester extreme pressure friction reducer, 16 parts of potassium chloride, 3 parts of polyamine inhibitor, 300 parts of weighting agent, 400 parts of water;

[0041] The composite plugging agent is a mixture of 16 parts of nitrile latex and 8 parts of nano-strengthening agent; the nano-strengthening agent is modified porous SiO 2 Nanoparticles, the particle size range is 10-100nm, the pore size range is 2-4nm, porous SiO 2 C8-C18 groups are grafted on the surface of nanoparticles, the groups do not contain ring structures, contain amino, carboxyl and mercapto functional groups, and 6% of the hydrogen atoms in the gro...

Embodiment 3

[0046] A high-performance water-based drilling fluid for maintaining stable shale strength, comprising the following raw materials in parts by weight: 12 parts of bentonite for drilling, 1.0 parts of sodium hydroxide, 30 parts of composite plugging agent, 20 parts of fluid loss reducer, polymer 15 parts of alcohol anti-slump agent, 12 parts of long-chain alcohol amine ester extreme pressure friction reducer, 20 parts of potassium chloride, 4 parts of polyamine inhibitor, 400 parts of weighting agent, 400 parts of water;

[0047] The composite plugging agent is a mixture of 18 parts of styrene latex and 12 parts of nano-strengthening agent; the nano-strengthening agent is modified porous SiO 2 Nanoparticles, the particle size range is 400-600nm, the pore size range is 20-30nm, porous SiO 2 C16-C36 groups are grafted on the surface of nanoparticles, which contain benzene rings, amino and carboxyl functional groups, and 30% of the hydrogen atoms in the groups are replaced by fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com