Efficient green manufacturing process of amino acid

A manufacturing process and green manufacturing technology, applied in microorganism-based methods, microorganisms, bacteria, etc., can solve the problems of large amount of acid and alkali, high Baume degree and viscosity of waste liquid, environmental pollution, etc., and reduce the amount of acid and alkali used. and water consumption, reduce Baume degree and viscosity, and improve the effect of greening level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] An efficient green manufacturing process for amino acids, which includes the following steps:

[0041] 1) An optimized glutamic acid fermentation medium, which includes fermentation medium A and fermentation medium B; the fermentation medium A is added first, and then the fermentation medium B is added at intervals of 24 hours.

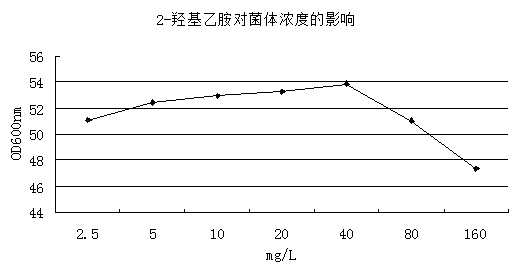

[0042] The preparation method of described fermentation medium A is: get each raw material: glucose 80g / L, yeast extract 20g / L, K 2 HPO 4 2g / L, MgSO 4 ·7H 2 O 50mg / L, 2-hydroxyethylamine 40mg / L, CeCl 3 10mg / L, MnSO 4 ·H 2 O 3mg / L, FeSO 4 ·7H 2 O 3mg / L, VB 1 10mg / L, biotin 7μg / L; After mixing all raw materials evenly, adjust the pH to 6.5, sterilize at 121°C for 15min, and cool naturally to prepare fermentation medium A;

[0043] The preparation method of the fermentation medium B is as follows: take each raw material: succinic acid 5g / L, urea 2g / L, chitosan 80mg / L; after stirring each raw material evenly, adjust the pH to 6.5, and ster...

Embodiment 2

[0049] An efficient green manufacturing process for amino acids, which includes the following steps:

[0050] 1) An optimized glutamic acid fermentation medium, which includes fermentation medium A and fermentation medium B; the fermentation medium A is added first, and then the fermentation medium B is added at intervals of 24 hours.

[0051] The preparation method of described fermentation medium A is: get each raw material: glucose 100g / L, yeast extract 25g / L, K 2 HPO 4 1g / L, MgSO 4 ·7H 2 O 70mg / L, 2-hydroxyethylamine 20mg / L, CeCl 3 5mg / L, MnSO 4 ·H 2 O 2mg / L, FeSO 4 ·7H 2 O 2mg / L, VB 1 5mg / L, biotin 5μg / L; After mixing all raw materials evenly, adjust the pH to 6.5, sterilize at 121°C for 15min, and cool naturally to prepare fermentation medium A;

[0052] The preparation method of the fermentation medium B is as follows: take each raw material: succinic acid 7g / L, urea 2g / L, chitosan 50mg / L; after stirring each raw material evenly, adjust the pH to 6.5, and ster...

Embodiment 3

[0057] 1. CeCl 3 Effects of rare earth salts on cell concentration, glutamic acid content and sugar-acid conversion rate.

[0058] The fermentation medium is: glucose 80g / L, yeast extract 20g / L, K 2 HPO 4 2g / L, MgSO 4 ·7H 2 O 50mg / L, CeCl 3 0-40mg / L, MnSO 4 ·H 2 O 3mg / L, FeSO 4 ·7H 2 O 3mg / L, VB 1 10mg / L, biotin 7μg / L;

[0059] The fermentation process is the same as in Example 1, and the 100L fermenter contains 70L fermentation medium.

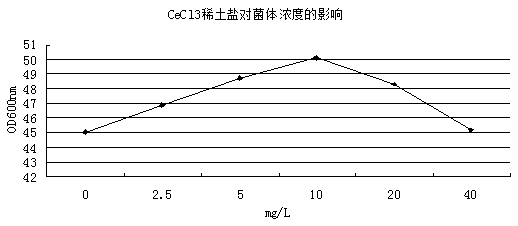

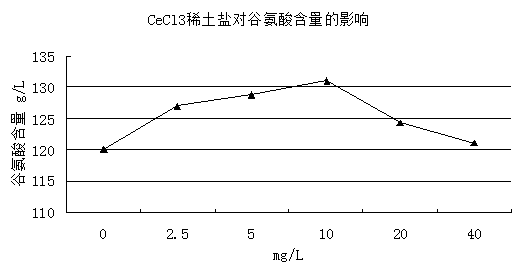

[0060] Set CeCl 3 The added concentration is 0, 2.5, 5, 10, 20, 40mg / L, such as Figure 1-2 As shown, with CeCl 3 The concentration of bacteria and glutamic acid content increased with the increase of the amount of addition. When the amount of addition was 10mg / L, the concentration of bacteria and glutamic acid content reached the peak value, and then showed a downward trend, but during the whole process, sugar-acid The conversion did not change significantly (figure not shown); indicating that CeCl 3 Rare earth salts can pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com