Method for manufacturing superconducting cable conductor film

A superconducting cable and thin film technology, which is applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of inability to deposit uniform thin films on non-planar substrates, small thin film area, and poor uniformity, so as to avoid Diaphragm leak phenomenon, simple equipment, good density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

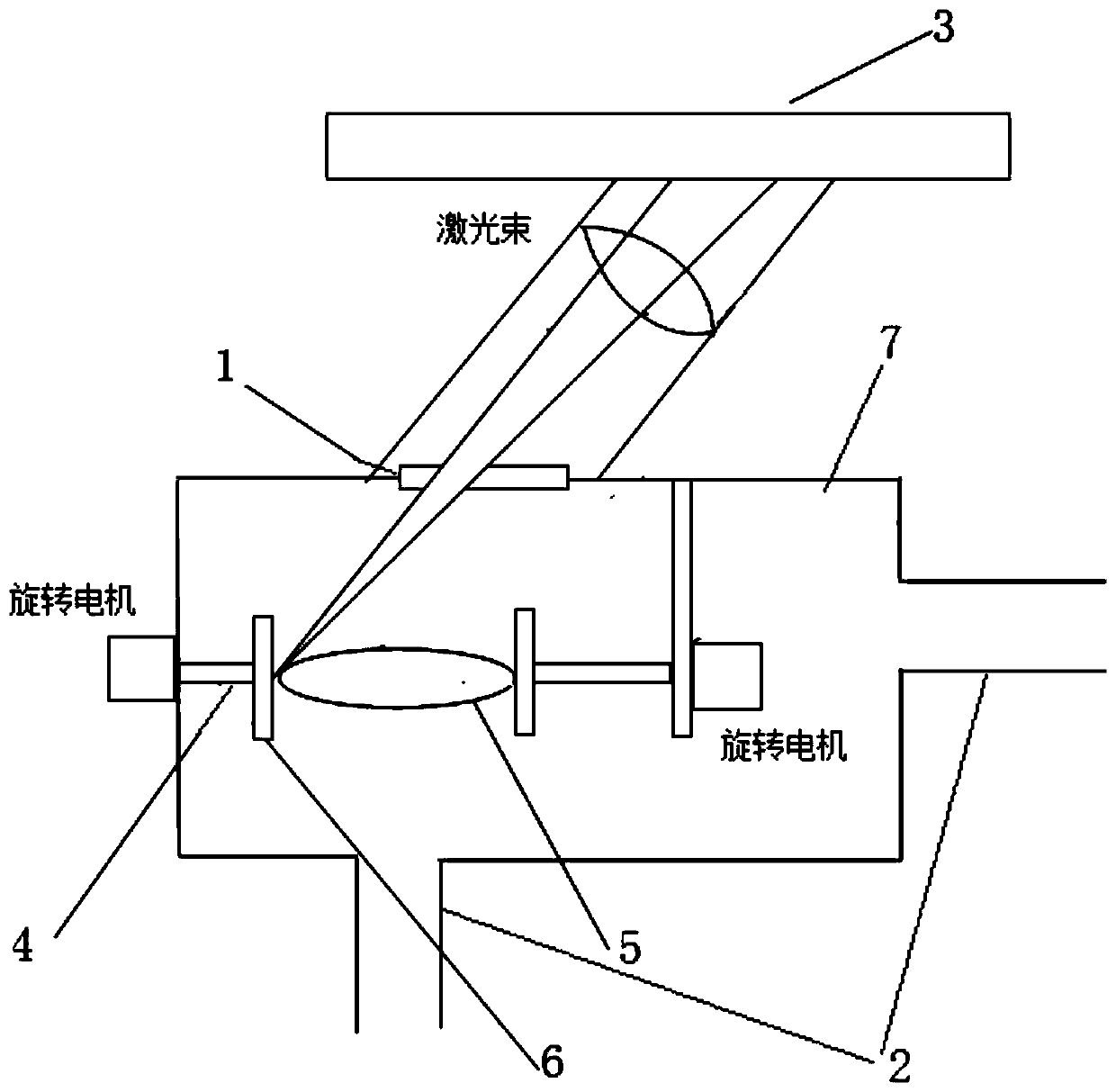

[0022] A method for manufacturing a film for a superconducting cable conductor, using a pulsed laser deposition molecular beam epitaxy film preparation system to produce a substrate film, such as figure 1 As shown, all components of the system are thickened stainless steel components, equipped with two-way observation port, laser bombardment window 1, gas inlet and outlet 2, equipped with turbomolecular pump, excimer pulse laser 3. The subject part is the substrate surface deposition chamber. The deposition chamber is equipped with a laser bombardment target seat 4, a rotating substrate heating base 5, a laser bombardment window 1 and the like. The spare materials include cylindrical iron-based superconductor target 6, oxygen source, argon gas source, hydrochloric acid solution (50%), deionized water, acetone, an appropriate amount of absolute ethanol, and an ultrasonic generator.

[0023] Connect the equipment of the preparation system well, power on and debug and make it re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com