Technology for preparing hippophae rhamnoides fruit juice beverage by quick-freezing separation and superhigh pressure sterilization

A technology for ultra-high pressure sterilization and seabuckthorn juice, applied in ultra-high pressure food processing, preservation of fruits/vegetables through freezing/refrigeration, food science, etc., can solve the problem of destroying nutrients and aromatic substances, degradation of active ingredients, long storage time, etc. problem, to achieve the effect of easier absorption of nutrients, stable performance, and uniform raw material composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

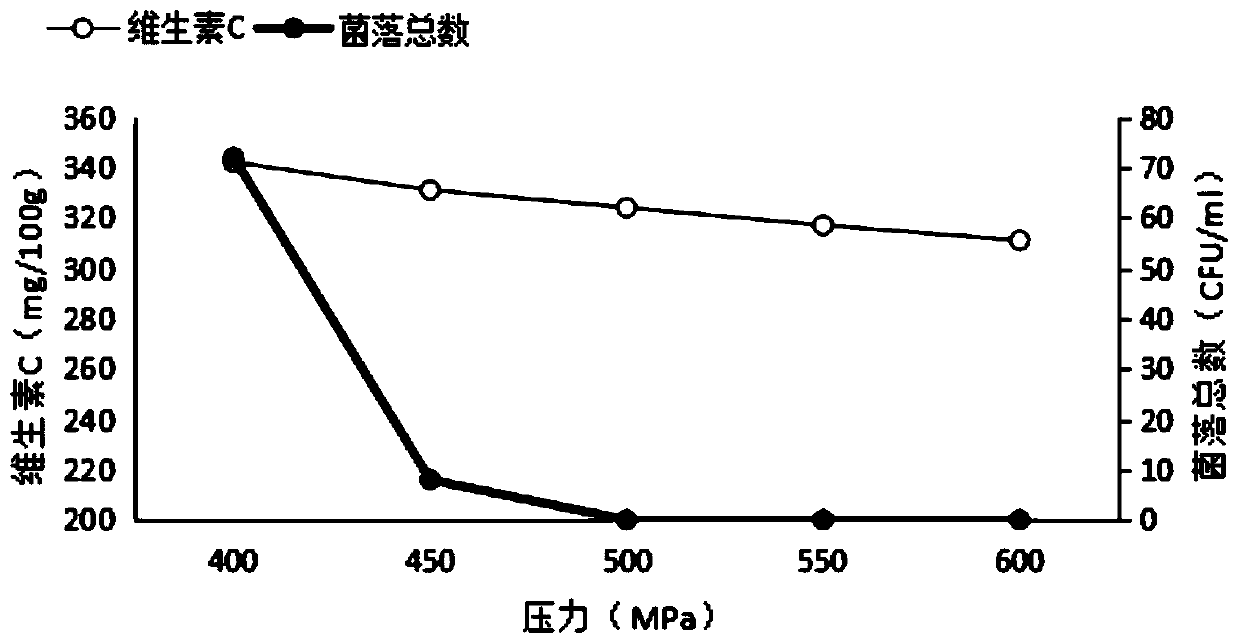

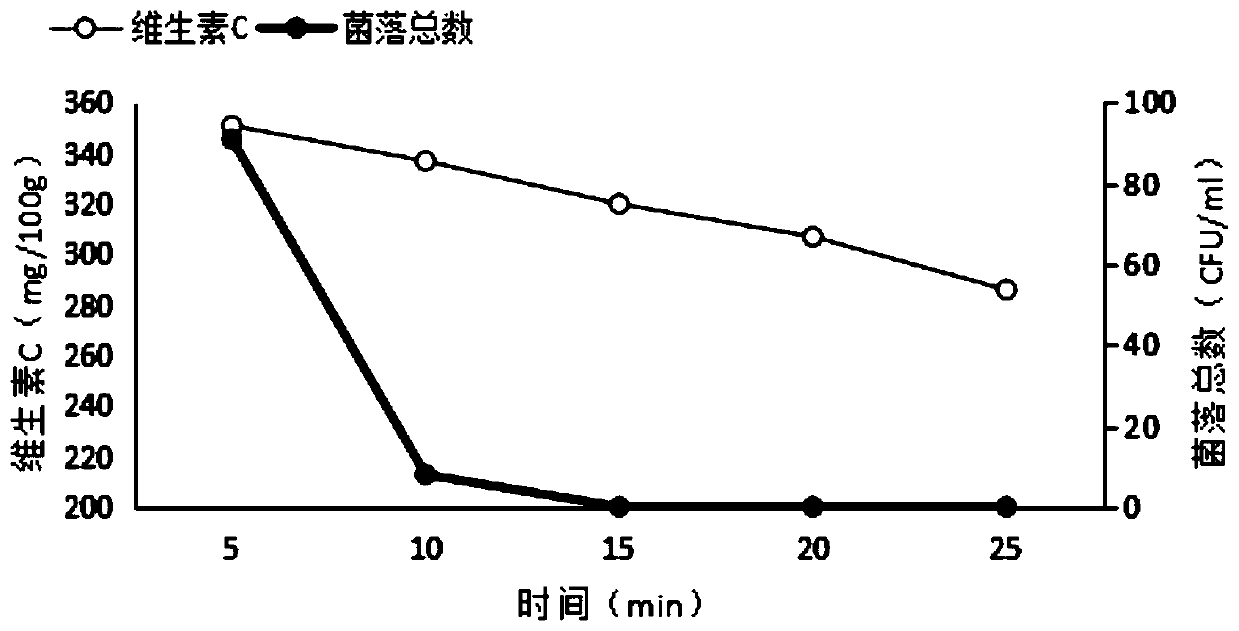

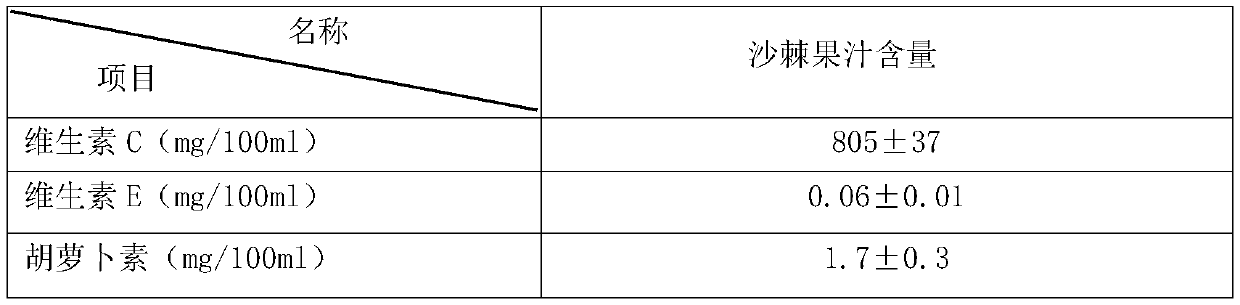

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing by specific embodiment:

[0025] 1. Materials and methods

[0026] 1.1 Raw materials: seabuckthorn fresh fruit: origin Datong County; fructooligosaccharide liquid; steviol glycosides.

[0027] 1.2 Instruments and equipment

[0028] SD-CG-5 type fruit thresher (Henan Xinxiang Shengda Technology Co., Ltd.), SK-DJ-3 type beater (Beijing Aeronautical Manufacturing Engineering Research Institute 202 Center), 2000L enzymatic hydrolysis tank (Jiangsu Kewei Machinery Co., Ltd.) , 2000L batching tank (Hengyang Tianda Pharmaceutical and Chemical Equipment Machinery Co., Ltd.), 130G-L colloid mill, GYB homogenizer (Shanghai Donghua High Pressure Homogenizer Factory), horizontal bag-fill-seal packaging machine ( Kunshan Shangwei Packaging Co., Ltd.), ultra-high pressure sterilizer (Shanxi Sanshuihe Company).

[0029] 2. Process steps

[0030] 2.1 Quick freezing and peeling of branches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com