Self-supporting water electrolysis material with dual carbon sandwich structure and preparation method thereof

A sandwich structure, self-supporting technology, applied in the direction of electrolysis process, electrolysis components, chemical instruments and methods, etc., to achieve the effect of good conductivity, excellent activity, and wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

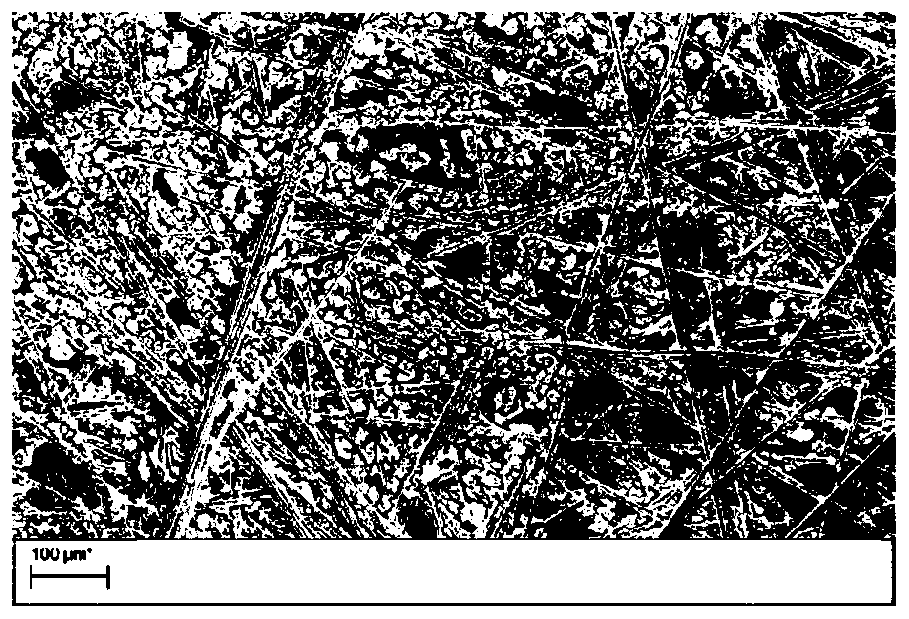

Image

Examples

Embodiment 1

[0027] 1. Select carbon paper as the substrate, place it in ultrapure water and ethanol for 60 minutes, and then place it in a vacuum oven to dry at 80°C for 12 hours.

[0028] 2. Dissolve 1.7mg of ammonium molybdate and 7mg of thiourea in 2mL of water, then add 50mg of silicon dioxide (100nm, 30wt.%), stir and mix well, and then sonicate for 60min.

[0029] 3. Take the mixed solution in step 2 and drop-coat it directly on the carbon paper, so that the precursor is evenly loaded on the carbon paper. After drying at room temperature, place it in a vacuum dryer and dry it for 10 hours at a drying temperature of 80°C; Chemical vapor deposition method, the obtained product was transferred to a tube furnace, under an argon atmosphere, the temperature was programmed to rise to 400°C at a rate of 10°C / min, the gas flow rate was 80mL / min, and then kept for 240min.

[0030] 4. Seal the product obtained in step 3 and place it in 50mL hydrofluoric acid solution (10wt.%) for 120min. After...

Embodiment 2

[0033] 1. Select carbon cloth as the substrate, place it in ultrapure water and ethanol for ultrasonic cleaning for 60 minutes, and then dry it in a vacuum oven at 80°C for 12 hours.

[0034] 2. Dissolve 1.7mg of ammonium molybdate and 7mg of thiourea in 2mL of water, then add 50mg of silicon dioxide (100nm, 30wt.%), stir and mix, and then sonicate for 120min.

[0035] 3. Take the mixed solution in step 2 and drop-coat it directly on the carbon cloth, so that the precursor is evenly loaded on the carbon cloth. After drying at room temperature, place it in a vacuum dryer for 10 hours at a drying temperature of 60°C; Chemical vapor deposition method, the obtained product was transferred to a tube furnace, under an argon atmosphere, the temperature was programmed to rise to 400°C at a rate of 10°C / min, the gas flow rate was 80mL / min, and then kept for 240min.

[0036]4. Seal the product obtained in step 3 and place it in 50mL hydrofluoric acid solution (10wt.%) for 120min. After ...

Embodiment 3

[0039] 1. Select carbon felt as the substrate, place it in ultrapure water and ethanol in order to ultrasonically clean it for 60 minutes, and then place it in a vacuum oven at 80°C for 12 hours.

[0040] 2. Dissolve 1.7mg of ammonium molybdate and 7mg of thiourea in 2mL of water, then add 50mg of silicon dioxide (100nm, 30wt.%), stir and mix well, and then sonicate for 80min.

[0041] 3. Take the mixed solution in step 2 and drop-coat it directly on the carbon felt, so that the precursor is evenly loaded on the carbon felt. After drying at room temperature, place it in a vacuum dryer for 10 hours at a drying temperature of 100°C; Chemical vapor deposition method, the obtained product was transferred to a tube furnace, under an argon atmosphere, the temperature was programmed to rise to 400°C at a rate of 10°C / min, the gas flow rate was 80mL / min, and then kept for 240min.

[0042] 4. Seal the product obtained in step 3 and place it in 50mL hydrofluoric acid solution (10wt.%) f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap