Method for preparing modified boron nitride nanosheets by water-phase shearing method

A technology of boron nitride and nanosheets, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problem of increasing the risk and complexity of experiments, destroying the lattice structure of boron nitride, reducing the performance of boron nitride, etc. problems, to achieve the effect of controllable peeling process, simple operation, and improved stability and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

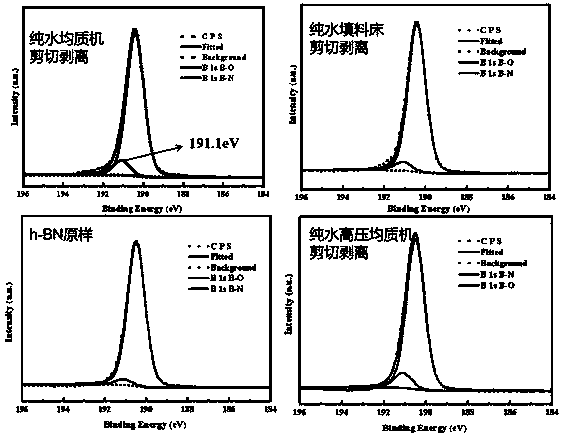

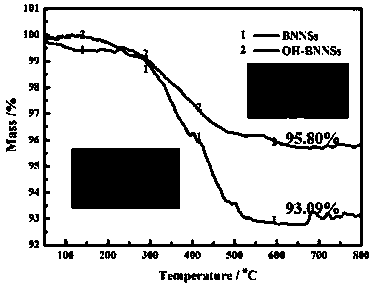

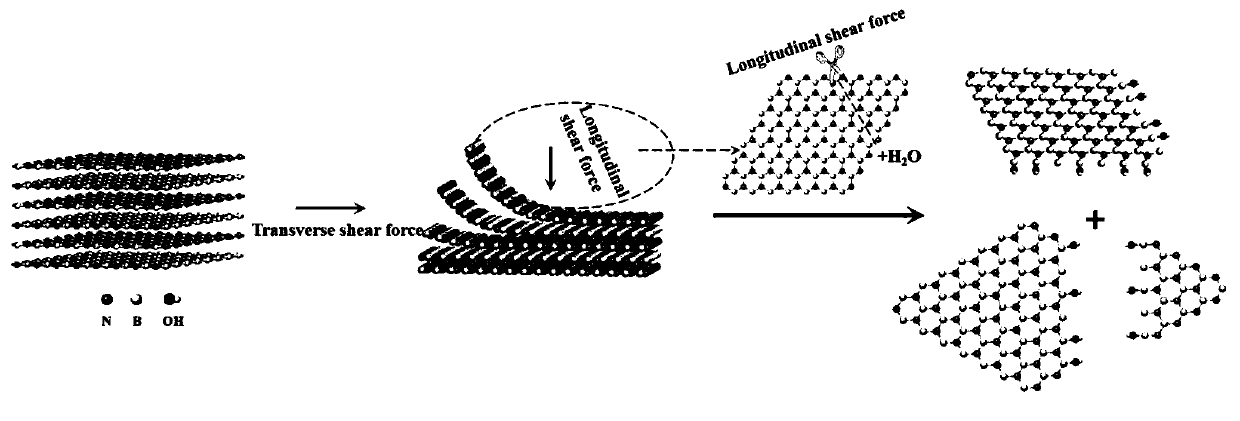

[0024] Embodiment 1, preparing boron nitride nanosheets;

[0025] First weigh 0.5g of sodium lauryl sulfate and dissolve it in 500ml deionized water, then weigh 10g of h-BN and disperse it into the prepared aqueous solution of sodium lauryl sulfate, the mixture of sodium lauryl sulfate and h-BN The mass ratio is 1:20.

[0026] The shearing homogenizer shears and strips the prepared h-BN suspension, the speed of the shearing homogenizer is 6000r / min, and the shearing stripping time is 14h. Afterwards, the suspension was centrifuged at a speed of 6000 r / min for 10 minutes, and the supernatant was taken to obtain a OH-BNNSs dispersion with a concentration of 0.88 mg / ml. The obtained supernatant was repeatedly filtered, washed, and freeze-dried to obtain OH-BNNSs powder.

[0027] The shear type homogenizer described in the present invention is the FJ300-SH digital display high-speed dispersion homogenizer produced by Shanghai Specimen Model Factory.

Embodiment 2

[0029] The difference from Example 1 is that the surfactant used is dodecyl hydroxypropyl sulfobetaine, and the rest of the process is the same. After shearing and stripping, the concentration of the supernatant is 0.82mg / ml.

Embodiment 3

[0031] The difference from Example 1 is that the surfactant used is polyvinyl alcohol, and the rest of the process is the same. After shearing and stripping, the concentration of the supernatant is 0.93 mg / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com