Environment-friendly graphene oxide modified ultra-high performance concrete and preparation method thereof

An ultra-high performance, environmentally friendly technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of low buckling ratio and toughness of concrete, avoid environmental pollution risks, save costs, and improve buckling. The effect of ratio and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

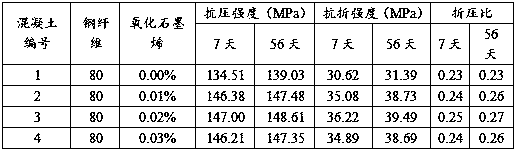

[0027] Example 1: Comparison of the influence of the addition amount of graphene oxide in environmentally friendly graphene oxide modified ultra-high performance concrete.

[0028] Including cementitious materials consisting of 401.50 parts of cement, 159.40 parts of silica fume, 318.79 parts of fly ash, and 82.71 parts of slag powder, quartz sand composed of 543.96 parts of coarse quartz sand, 391.65 parts of medium quartz sand, and 315.5 parts of fine quartz sand, It also includes 80 parts of steel fiber, water, graphene oxide and polycarboxylate high-performance water reducer, the mass ratio of water to cementitious material is 0.16, and the mass of graphene oxide is 0.01-0.03% of the mass of cement The mass of the polycarboxylic acid high-performance water reducer is 0.3% of the mass of the gelling material.

[0029] Concrete selected raw material ratio is as shown in Table 1:

[0030] Table 1

[0031]

[0032] Step by step to make ultra-high performance concrete:

...

Embodiment 2

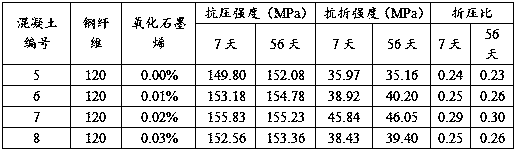

[0045] Example 2: Comparison of the influence of the addition amount of graphene oxide in environmentally friendly graphene oxide modified ultra-high performance concrete.

[0046] According to the proportion of raw materials as shown in Table 3:

[0047] table 3

[0048]

[0049] Four groups of ultra-high performance concrete were prepared, and group 5 did not contain graphene oxide. The 7-day and 56-day compressive strength tests, and the 7-day and 56-day flexural strength tests were carried out on the 4 groups of concrete samples respectively. The results are shown in Table 4.

[0050] Table 4

[0051]

[0052] The results are similar to Example 1, that is, under the same steel fiber ratio, the appropriate amount of graphene oxide increases the compressive strength, flexural strength and folding ratio of concrete. However, when the content of graphene oxide is 0.03%, the compressive strength, flexural strength and folding ratio begin to decrease, so the optimized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com