Heparin sodium high in clarity

A heparin sodium, high-purity technology, applied in the direction of blood diseases, extracellular fluid diseases, non-central analgesics, etc., can solve the problems of reduced insoluble particles, residual protein and nucleic acid, etc., to achieve reduced insoluble particles, low cost, The effect of simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

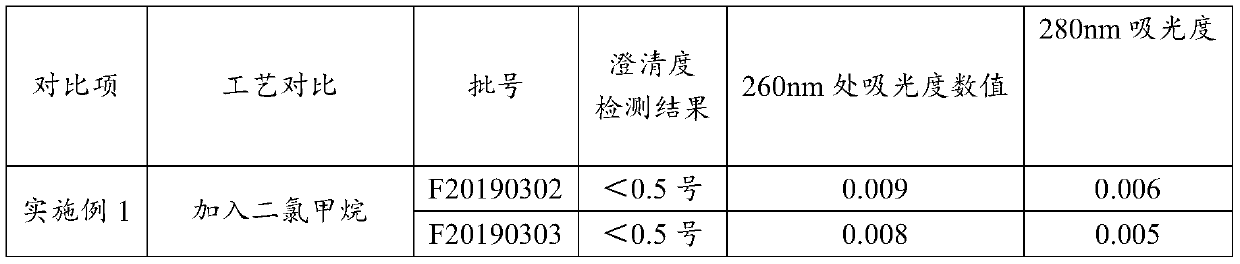

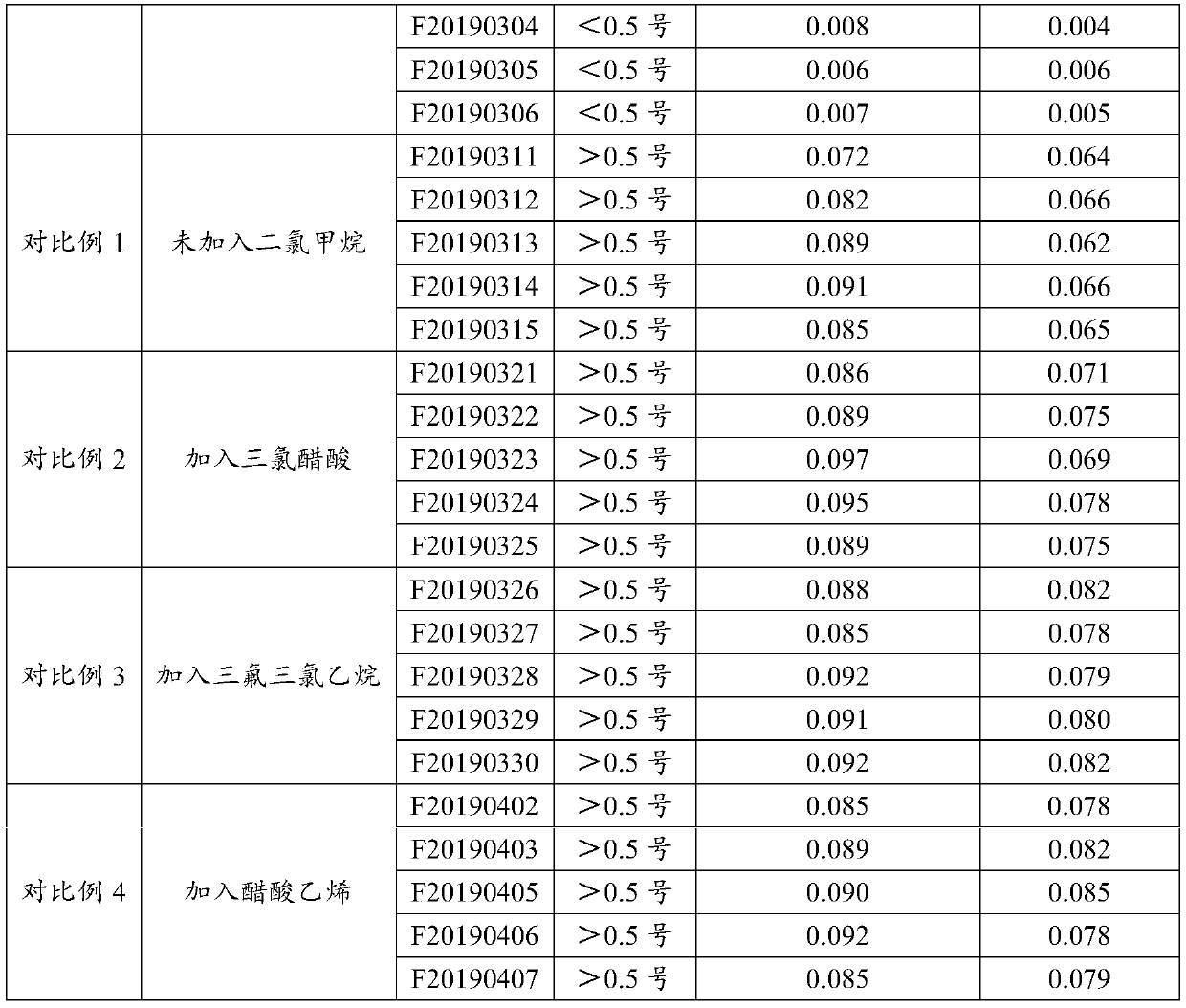

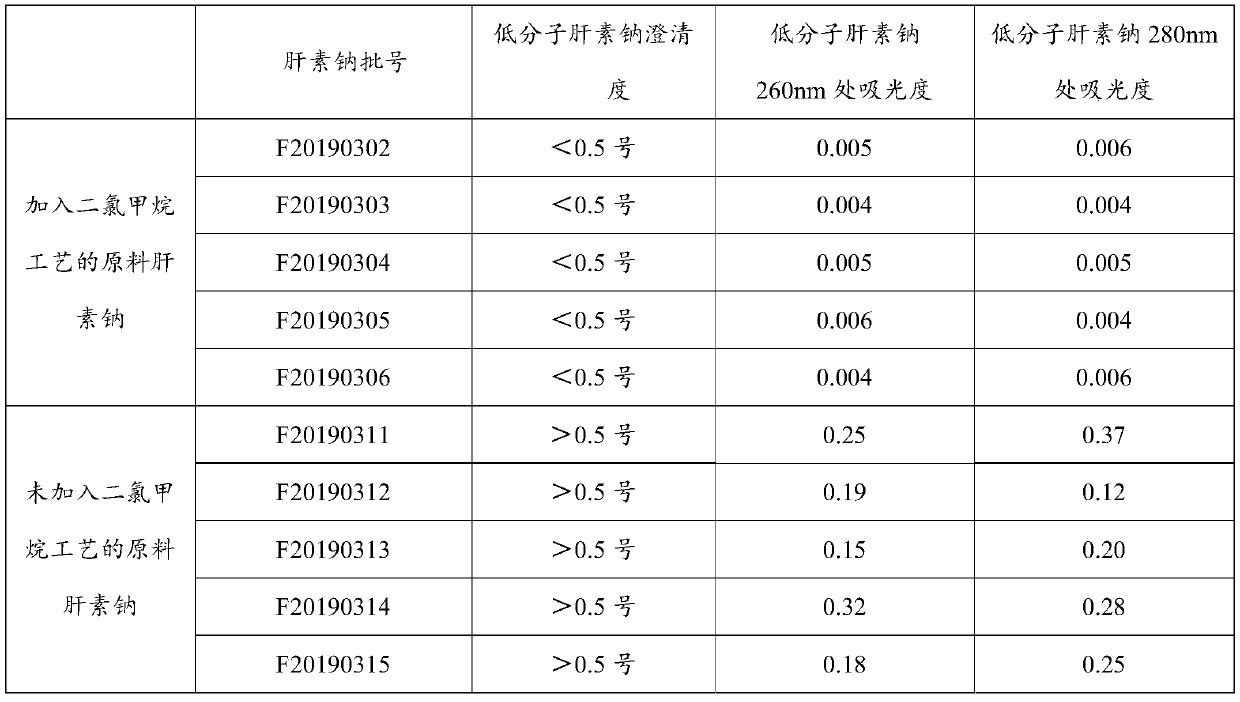

Examples

Embodiment 1

[0039] A preparation process for high-purity heparin sodium, specifically comprising the following steps:

[0040] 1. Enzymatic deproteinization: dilute the crude heparin sodium with purified water to a 10% (w / v) concentration solution, raise the temperature to 45.0°C, adjust the pH value to 7-9, add the dissolved 2709 protease, and keep the temperature and pH, keep stirring for 6 hours, then add calcium chloride solution, keep stirring, and filter with plate and frame filter;

[0041]2. Oxidation: adjust the temperature of the filtrate to room temperature °C, adjust the pH value of the feed liquid to 10-11 with 4mol / L sodium hydroxide solution, and add 30% of the feed liquid volume to 1% of the feed liquid volume under the condition of maintaining pH 10-11. For hydrogen peroxide oxidation, check the pH change of the feed liquid every half hour. If the pH is lower than 10, adjust it to the range of 10-11 in time, and add 0.5% hydrogen peroxide. The overall hydrogen peroxide ad...

Embodiment 2

[0048] A preparation process for high-purity heparin sodium, specifically comprising the following steps:

[0049] 1. Enzymatic deproteinization: Dilute the crude heparin sodium with purified water to a solution with a concentration of 5% (w / v), raise the temperature to 55.0°C, adjust the pH value to 7-9, add dissolved 2709 protease, and keep the temperature and pH, keep stirring for 6 hours, then add calcium chloride solution, keep stirring, and filter with plate and frame filter;

[0050] 2. Oxidation: adjust the temperature of the filtrate to room temperature °C, adjust the pH value of the feed liquid to 10-11 with 4mol / L sodium hydroxide solution, and add 30% of the feed liquid volume to 1% of the feed liquid volume under the condition of maintaining pH 10-11. For hydrogen peroxide oxidation, check the pH change of the feed liquid every half hour. If the pH is lower than 10, adjust it to the range of 10-11 in time, and add 0.5% hydrogen peroxide. The overall hydrogen perox...

Embodiment 3

[0057] A preparation process for high-purity heparin sodium, specifically comprising the following steps:

[0058] 1. Enzymatic deproteinization: dilute the crude heparin sodium with purified water to a solution with a concentration of 15% (w / v), raise the temperature to 35.0°C, adjust the pH value to 7-9, add dissolved 2709 protease, and keep the temperature and pH, after stirring for 6 hours, add calcium chloride solution, continue stirring, and filter with a plate and frame filter;

[0059] 2. Oxidation: adjust the temperature of the filtrate to room temperature °C, adjust the pH value of the feed liquid to 10-11 with 4mol / L sodium hydroxide solution, and add 30% of the feed liquid volume to 1% of the feed liquid volume under the condition of maintaining pH 10-11. For hydrogen peroxide oxidation, check the pH change of the feed liquid every half hour. If the pH is lower than 10, adjust it to the range of 10-11 in time, and add 0.5% hydrogen peroxide. The overall hydrogen pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com