Low-density environment-friendly ablation-resistant ethylene propylene rubber and preparation method thereof

An ethylene-propylene rubber and ablation-resistant technology, which is applied in the field of rubber manufacturing, can solve the problems of poor low temperature resistance, high density, and inability to meet the functional requirements of new flight equipment, and achieve low density, low odor, and good ablation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

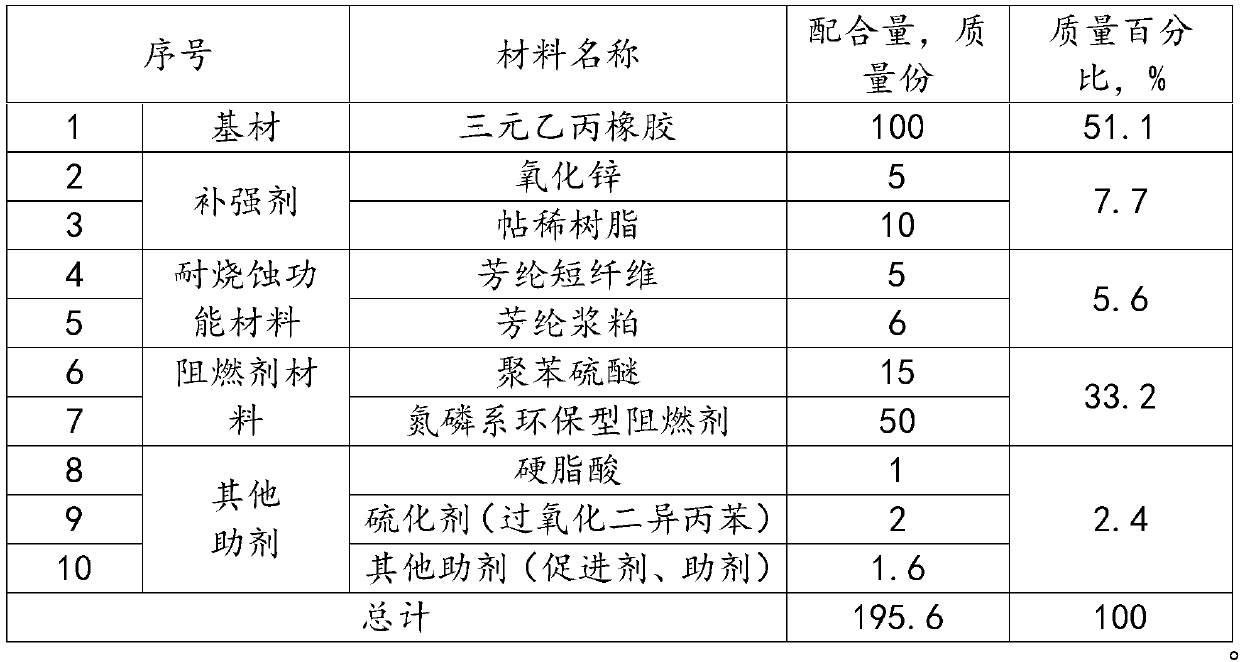

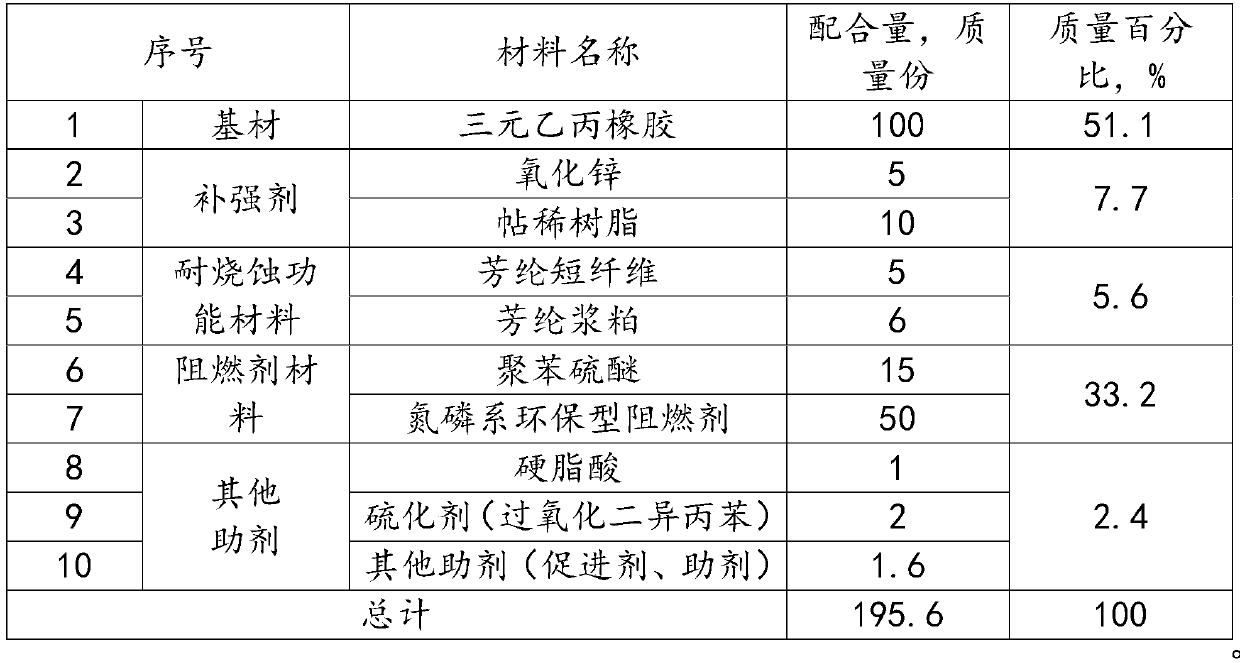

[0036] The components and proportioning scheme of the above-mentioned rubber are shown in Table 1 below:

[0037]

[0038]

[0039] Table 1.

[0040] The preparation method of the compound rubber material of above-mentioned rubber comprises the following steps:

[0041] Use a double-roll mill for material mixing, adjust the roller distance to 1-2 mm, and add EPDM raw rubber at a temperature of 0-50°C; after the raw rubber is pressed into continuous sheets and translucent, adjust the kneading Machine roll distance to 3 ~ 4mm, add 5 grams of zinc oxide, 50 grams of nitrogen-phosphorus environmentally friendly flame retardants, 1 gram of stearic acid, 2 grams of dicumyl peroxide, 1.6 grams of accelerators and additives, polystyrene 15 grams of sulfide, 6 grams of aramid pulp, 10 grams of thin resin, and 5 grams of aramid short fiber. After the feeding is completed, the film is rolled 5 times and the film is removed; the film that has been rolled is ground by a three-roller...

Embodiment 2

[0065] The components and proportioning scheme of the rubber of the present embodiment are shown in Table 3 below:

[0066]

[0067] table 3.

[0068] In this example, other preparation steps are consistent with Example 1.

Embodiment 3

[0070] The components and proportioning scheme of the rubber of the present embodiment are shown in Table 4 below:

[0071]

[0072]

[0073] Table 4.

[0074] In this example, other preparation steps are consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com