Cyanide-free tin electroplating solution and electroplating method thereof

A technology of electroplating solution and tin salt, which is applied in the field of cyanide-free electroplating solution and its electroplating, which can solve problems such as the influence of coating color, slow deposition rate, easy mold growth in the plating solution, etc., and achieve excellent electroplating effect, better use feeling, good looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

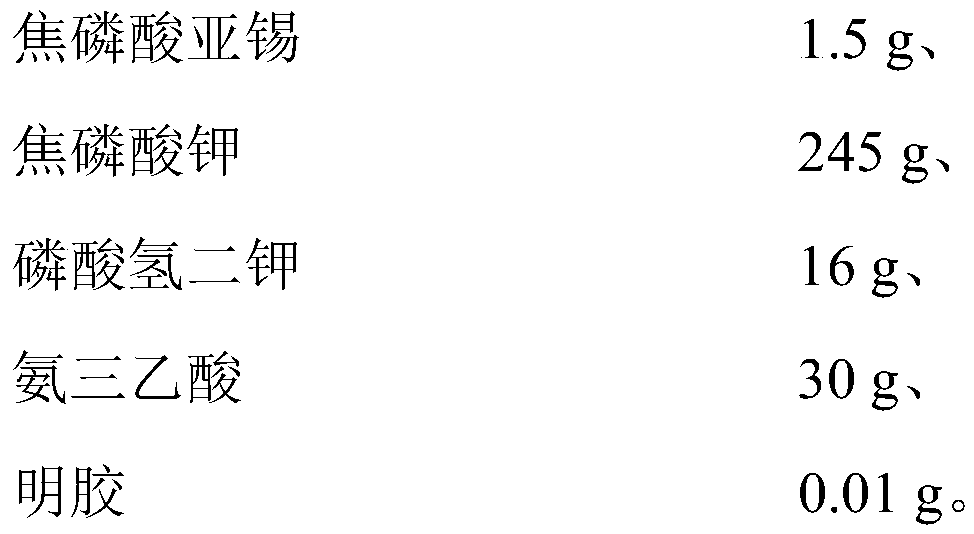

[0033] The present embodiment electroplating solution has included following components:

[0034]

[0035] The electroplating method using the present embodiment electroplating solution is:

[0036] (1) Preparation of electroplating solution: dissolve the following components in hot water at 25° C. to form an electroplating solution, containing 245 g of potassium pyrophosphate in the described per liter of electroplating solution; 16 g of dipotassium hydrogen phosphate; 30 g of nitrilotriacetic acid and 0.01 g of gelatin;

[0037] (2) Use pH test paper to detect the pH value of the solution, and use sodium hydroxide or phosphoric acid to adjust so that the pH value of the solution is 8;

[0038] (3) Use distilled water to configure stannous pyrophosphate solution, stir to make it fully dissolve;

[0039] (4) Add the electroplating solution obtained in step (1) into the electrolytic tank, use a current of 0.15A, and electrolyze for 60 minutes under the condition of hot wate...

Embodiment 2

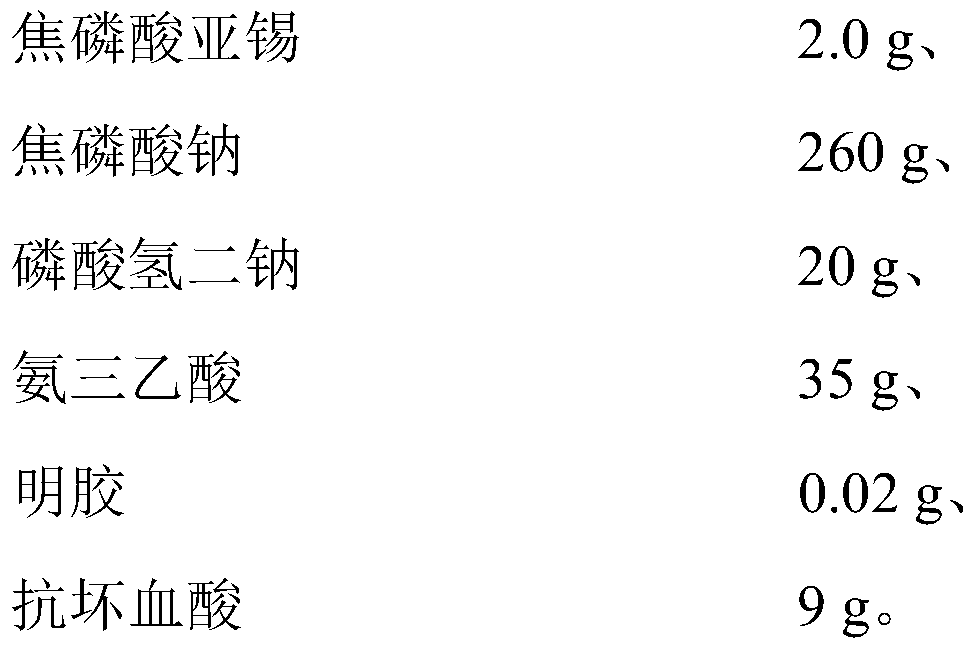

[0041] The present embodiment electroplating solution has included following components:

[0042]

[0043] The electroplating method using the present embodiment electroplating solution is:

[0044] (1) Preparation of electroplating solution: dissolving each raw material component in hot water to form an electroplating solution, containing 260g of pyrophosphate in the described per liter of electroplating solution; buffering agent 20g; auxiliary complexing agent 35g and gelatin 0.02g;

[0045] (2) Use pH test paper to detect the pH value of the solution, and use sodium hydroxide or phosphoric acid to adjust so that the pH value of the solution is 8;

[0046] (3) Use distilled water to dissolve ascorbic acid, configure antioxidant solution, stannous pyrophosphate solution, stir to make it fully dissolved;

[0047] (4) Add the electroplating solution obtained in step (1) into the electrolytic tank, use a current of 0.25A, electrolyze for 70 minutes under hot water conditions...

Embodiment 3

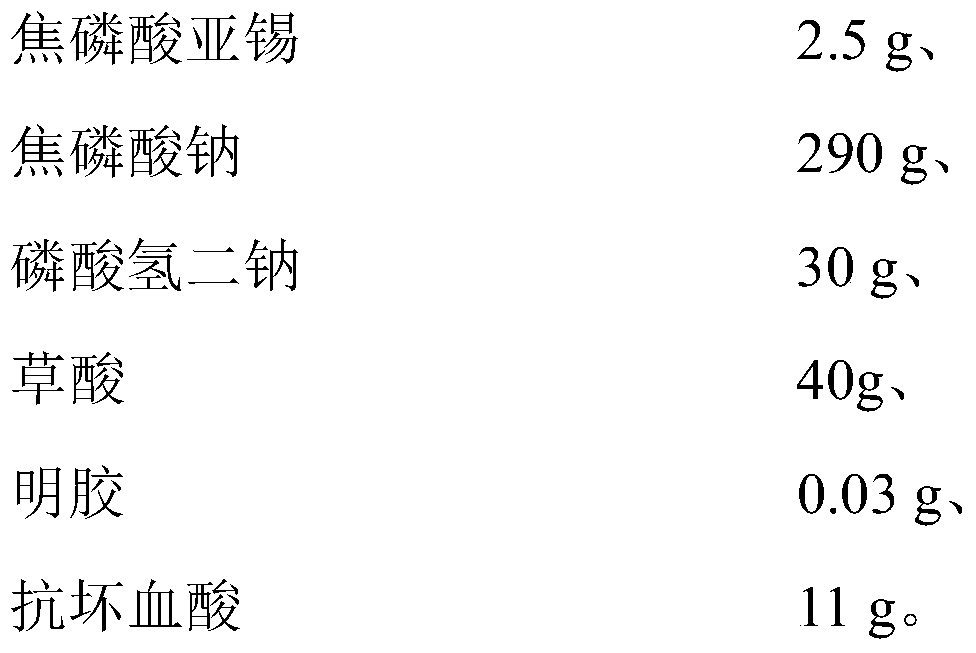

[0049] The present embodiment electroplating solution has included following components:

[0050]

[0051] The electroplating method of cyanide-free electroplating solution is the same as embodiment 2 in the present embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com